Search Results (Searched for: THCAD)

- rodw

03 Feb 2025 12:05

Replied by rodw on topic Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Category: Show Your Stuff

QTplasmac stores the THCAD scaling settings in the GUI as per the previous screen dump the OP shared.No, 7I96 TB2 pin 12 is the correct 5V source.

What are the scaling factors that you used?

(there must be a missing hal file where plasma voltage scaling/offset is done)

- Hakan

- Hakan

02 Feb 2025 20:42

EtherCAT IO and frequency counter for plasma cutter was created by Hakan

EtherCAT IO and frequency counter for plasma cutter

Category: Show Your Stuff

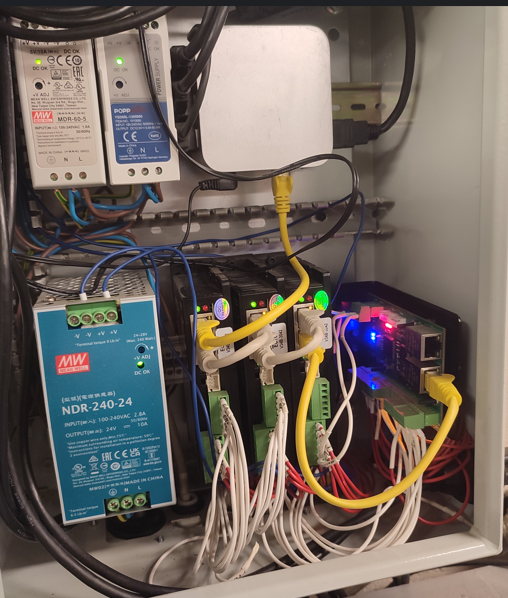

Here is my latest EtherCAT card, the EaserCAT 6000, with 12 digital inputs, 4 digital outputs, and one frequency counter input for THCAD output.

It's the one down in the corner. There are three RTelligent ECT60 EtherCAT stepper motor drivers as well.

The inputs are limit switches for X, Y, Z, e-stop, floating, break-away and arc-OK.

Plasma-on is controlled by output 1.

There is one frequency counter input. Come to think of it it wouldn't be difficult to add another frequency counter for ohmic sensing, but I don't think my plasma cutter supports that, a Herocut 55X.

More details are here, including all schematics and source code.

github.com/MetalMusings/MyOwnEtherCATDevice

I haven't been cutting a whole lot with it yet. The worry has been the frequency counter that had some interference, seems to have been due to poor cable choice. With that sorted, voltage reading is now stable and THC works just fine.

It's the one down in the corner. There are three RTelligent ECT60 EtherCAT stepper motor drivers as well.

The inputs are limit switches for X, Y, Z, e-stop, floating, break-away and arc-OK.

Plasma-on is controlled by output 1.

There is one frequency counter input. Come to think of it it wouldn't be difficult to add another frequency counter for ohmic sensing, but I don't think my plasma cutter supports that, a Herocut 55X.

More details are here, including all schematics and source code.

github.com/MetalMusings/MyOwnEtherCATDevice

I haven't been cutting a whole lot with it yet. The worry has been the frequency counter that had some interference, seems to have been due to poor cable choice. With that sorted, voltage reading is now stable and THC works just fine.

- Badutis

- Badutis

02 Feb 2025 17:10

Replied by Badutis on topic CNC Plasma cutters, DIY, building info and guide

CNC Plasma cutters, DIY, building info and guide

Category: Plasma & Laser

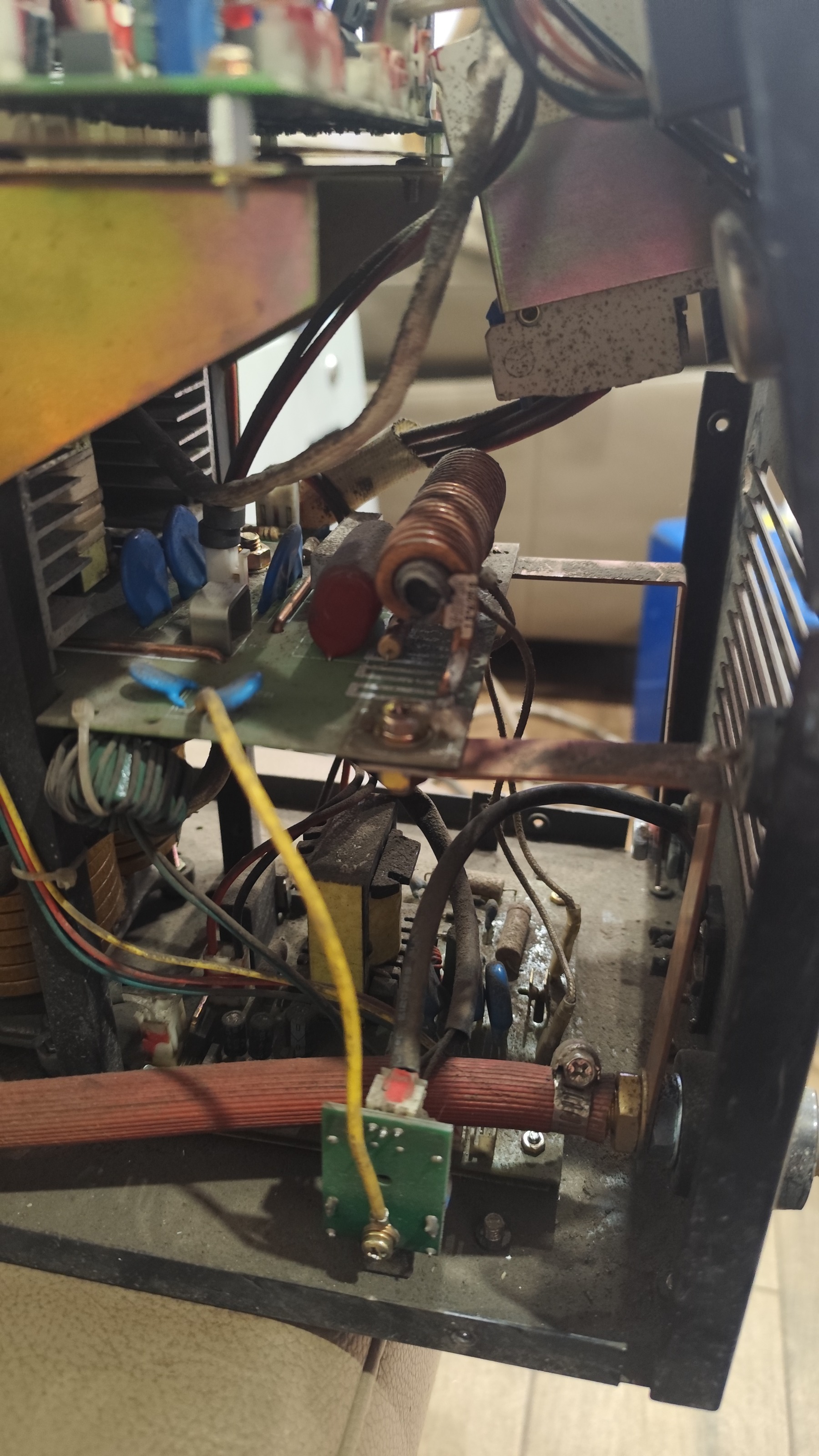

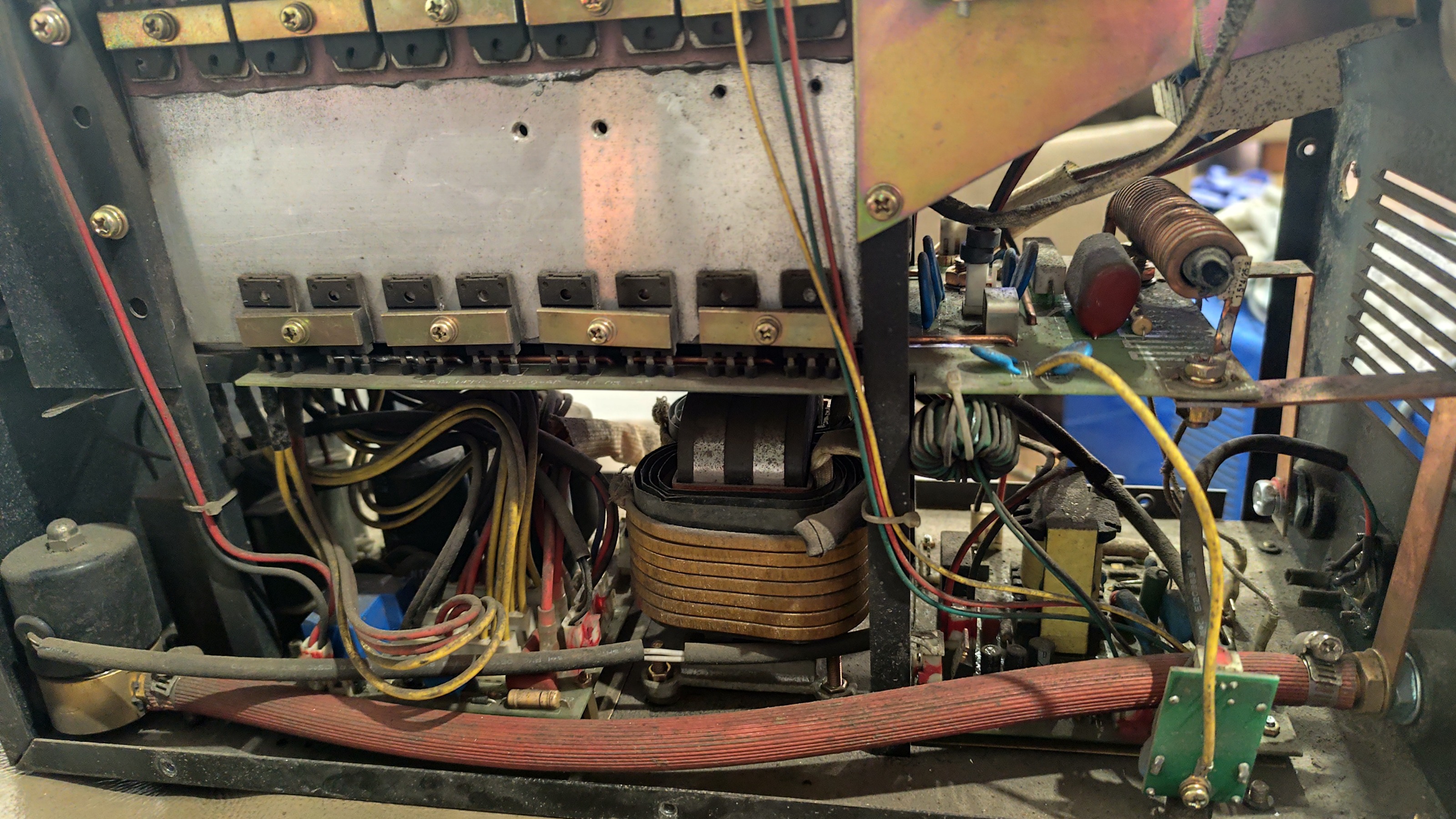

thanks tommylight for your quick reply. Well, I'm not sure about that in Arc Pilot, that's why I wrote likely. I relied on the information I was able to find on the Internet. However, I have no doubt that you are right and cutter is not an Arc Pilot. Does it change anything? I think I saw somewhere that you have implemented projects with HF plasma and THCAD300. Could you tell me where exactly those wires should be connected? anyway, if it is necessary to make this cutter work with CNC, I also have PROMA THC 150,

- rodw

02 Feb 2025 12:01

Replied by rodw on topic Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Category: Show Your Stuff

Well the THCAD data is in hal so you are nearly there

what have you got set for

Voltage scale and voltage offset here?

linuxcnc.org/docs/stable/html/plasma/qtp...lasma:parameters-tab

Maybe PCW can see something missing on the night shift...

what have you got set for

Voltage scale and voltage offset here?

linuxcnc.org/docs/stable/html/plasma/qtp...lasma:parameters-tab

Maybe PCW can see something missing on the night shift...

- RNJFAB

- RNJFAB

02 Feb 2025 11:05 - 02 Feb 2025 11:23

So i have done the calculator, and fudged the numbers to get the voltage back around 0v

Confirm - 1/32 setting on board.

Confirm - Plasma is set to 20:1.

Confirm - torch starts and the light on the THCAD 10 flashes faster.

Replied by RNJFAB on topic Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Category: Show Your Stuff

So i have done the calculator, and fudged the numbers to get the voltage back around 0v

Confirm - 1/32 setting on board.

Confirm - Plasma is set to 20:1.

Confirm - torch starts and the light on the THCAD 10 flashes faster.

- Badutis

- Badutis

02 Feb 2025 11:00

hi guys I bought a MESA 7I96+THCAD300 for my CNC plasma machine project a couple of years ago. So I don't really remember how and why I chose THCAD300, although I have plasma machines Stahlwerk CUT 70, as far as I know, with ARC pilot type ignition. And if I understand correctly I need THCAD 10? Is there any way to modify or adapt the THCAD300 I have to my needs? Should I buy a new one? If new, what kind?

Replied by Badutis on topic CNC Plasma cutters, DIY, building info and guide

CNC Plasma cutters, DIY, building info and guide

Category: Plasma & Laser

Warning: Spoiler!

- rodw

02 Feb 2025 07:18

Replied by rodw on topic Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Category: Show Your Stuff

So the 9v battery tells you it's working, The light in the board should flash faster at 9 volts

Make sure the scaling link on the board is set to 1/32. Next step is to check the encoder velocity in halshow. It should be hovering around the 0 volt frequency (1/32 thereof). if not, debug the reason

There are some encoder settings in hal but they appear to be set OK

Next step is to ensure the thcad calibration settings are set for qtplasmac. There is a link to an online calculator to determine the correct settings in the QTplasmac docs.

Make sure the scaling link on the board is set to 1/32. Next step is to check the encoder velocity in halshow. It should be hovering around the 0 volt frequency (1/32 thereof). if not, debug the reason

There are some encoder settings in hal but they appear to be set OK

Next step is to ensure the thcad calibration settings are set for qtplasmac. There is a link to an online calculator to determine the correct settings in the QTplasmac docs.

- RNJFAB

- RNJFAB

02 Feb 2025 04:57 - 02 Feb 2025 07:01

Replied by RNJFAB on topic Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Homemade CNC Plasma - hypertherm, Mesa, gear drives, nema 34.

Category: Show Your Stuff

not sure about debouncing on the limit switches.

Mesa 7i96,THCAD10, closed loop nema34. hypertherm xp45 with cpc port.

all fixed with the 24v field power. thanks Rod.

next problem is the thc is not reading. I have checked the THC with 9V battery and it works there, so guessing the problem lies in my INI or HAL files.

# Generated by PNCconf at Sun Feb 2 06:15:46 2025

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = T17

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = qtvcp qtplasmac

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/cnc/linuxcnc/nc_files

INCREMENTS = 10mm 1mm 100mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 83.333333

MAX_LINEAR_VELOCITY = 183.333333

MIN_LINEAR_VELOCITY = 1.666667

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

GEOMETRY = xyz

CYCLE_TIME = 100

[FILTER]

PROGRAM_EXTENSION = .ngc,.nc,.tap GCode File (*.ngc, *.nc, *.tap)

ngc = qtplasmac_gcode

nc = qtplasmac_gcode

tap = qtplasmac_gcode

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G21 G40 G49 G80 G90 G92.1 G94 G97 M52P1

SUBROUTINE_PATH = ./:../../nc_files

USER_M_PATH = ./:../../nc_files

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

CARD0=hm2_7i96.0

[HAL]

HALUI = halui

HALFILE = T17.hal

HALFILE = qtplasmac_comp.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 4

KINEMATICS = trivkins coordinates=XYYZ

[TRAJ]

SPINDLES = 3

COORDINATES = XYYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 18.33

MAX_LINEAR_VELOCITY = 183.33

NO_FORCE_HOMING = 1

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

# MAX_VEL & MAX_ACC need to be twice the corresponding joint value

MAX_VELOCITY = 366.6666666666667

MAX_ACCELERATION = 4000.0

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -5.0

MAX_LIMIT = 1300.0

[JOINT_0]

TYPE = LINEAR

HOME = 10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 183.33333333333334

MAX_ACCELERATION = 2000.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 229.17

STEPGEN_MAXACCEL = 2500.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 52.0833

MIN_LIMIT = -5.0

MAX_LIMIT = 1300.0

HOME_OFFSET = -10.000000

HOME_SEARCH_VEL = -50.000000

HOME_LATCH_VEL = -25.000000

HOME_FINAL_VEL = 16.666667

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Y]

# MAX_VEL & MAX_ACC need to be twice the corresponding joint value

MAX_VELOCITY = 366.6666666666667

MAX_ACCELERATION = 5000.0

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -5.0

MAX_LIMIT = 2520.0

[JOINT_1]

TYPE = LINEAR

HOME = 10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 183.33333333333334

MAX_ACCELERATION = 2500.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 229.17

STEPGEN_MAXACCEL = 3125.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 52.0833

MIN_LIMIT = -5.0

MAX_LIMIT = 2520.0

HOME_OFFSET = -10.000000

HOME_SEARCH_VEL = -50.000000

HOME_LATCH_VEL = -25.000000

HOME_FINAL_VEL = 16.666667

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = -2

[JOINT_2]

TYPE = LINEAR

HOME = 10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 183.33333333333334

MAX_ACCELERATION = 2500.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 229.17

STEPGEN_MAXACCEL = 3125.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 52.0833

MIN_LIMIT = -5.0

MAX_LIMIT = 2520.0

HOME_OFFSET = -10.000000

HOME_SEARCH_VEL = -50.000000

HOME_LATCH_VEL = -25.000000

HOME_FINAL_VEL = 16.666667

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = -2

#******************************************

#******************************************

[AXIS_Z]

# MAX_VEL & MAX_ACC need to be twice the corresponding joint value

MAX_VELOCITY = 66.66666666666667

MAX_ACCELERATION = 400.0

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -150.0

MAX_LIMIT = 5.0

[JOINT_3]

TYPE = LINEAR

HOME = -10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 33.333333333333336

MAX_ACCELERATION = 200.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 41.67

STEPGEN_MAXACCEL = 250.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 392.1569

MIN_LIMIT = -150.0

MAX_LIMIT = 5.0

HOME_OFFSET = 5.000000

HOME_SEARCH_VEL = 8.333333

HOME_LATCH_VEL = 8.333333

HOME_FINAL_VEL = -8.333333

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = 1

#******************************************

# Generated by PNCconf at Sun Jan 26 20:35:25 2025

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS num_spindles=[TRAJ]SPINDLES

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=0xxxxxxx"

setp [HMOT](CARD0).watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.y2,pid.z,pid.s

loadrt plasmac

addf [HMOT](CARD0).read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.y2.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf plasmac servo-thread

addf [HMOT](CARD0).write servo-thread

setp [HMOT](CARD0).dpll.01.timer-us -50

setp [HMOT](CARD0).stepgen.timer-number 1

# ---PLASMA INPUT DEBOUNCE---

#values for these are in custom.hal

loadrt dbounce names=db_breakaway,db_float,db_ohmic,db_arc-ok

addf db_float servo-thread

addf db_ohmic servo-thread

addf db_breakaway servo-thread

addf db_arc-ok servo-thread

# ---JOINT ASSOCIATED WITH THE Z AXIS---

net plasmac:axis-position joint.3.pos-fb => plasmac.axis-z-position

# ---PLASMA INPUTS---

# ---all modes---

net plasmac:float-switch => db_float.in

net plasmac:breakaway => db_breakaway.in

net plasmac:ohmic-probe => db_ohmic.in

net plasmac:ohmic-sense-in => plasmac.ohmic-sense-in

# ---modes 0 & 1

net plasmac:arc-voltage-in => plasmac.arc-voltage-in

# ---modes 1 & 2

net plasmac:arc-ok-in => db_arc-ok.in

# ---mode 2

net plasmac:move-up <= plasmac.move-up

net plasmac:move-down <= plasmac.move-down

# ---PLASMA OUTPUTS---

# ---all modes---

net plasmac:ohmic-enable <= plasmac.ohmic-enable

net plasmac:scribe-arm <= plasmac.scribe-arm

net plasmac:scribe-on <= plasmac.scribe-on

# external output signals

# --- PLASMAC:TORCH-ON ---

net plasmac:torch-on => [HMOT](CARD0).ssr.00.out-00

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= [HMOT](CARD0).gpio.000.in_not

# --- BOTH-HOME-X ---

net both-home-x <= [HMOT](CARD0).gpio.001.in_not

# --- BOTH-HOME-Y ---

net both-home-y <= [HMOT](CARD0).gpio.002.in_not

# --- BOTH-HOME-Y2 ---

net both-home-y2 <= [HMOT](CARD0).gpio.003.in_not

# --- BOTH-HOME-Z ---

net both-home-z <= [HMOT](CARD0).gpio.004.in_not

# --- PLASMAC:FLOAT-SWITCH ---

net plasmac:float-switch <= [HMOT](CARD0).gpio.005.in_not

# --- PLASMAC:BREAKAWAY ---

net plasmac:breakaway <= [HMOT](CARD0).gpio.006.in_not

# --- Encoder ---

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.01.dirsetup [JOINT_0]DIRSETUP

setp [HMOT](CARD0).stepgen.01.dirhold [JOINT_0]DIRHOLD

setp [HMOT](CARD0).stepgen.01.steplen [JOINT_0]STEPLEN

setp [HMOT](CARD0).stepgen.01.stepspace [JOINT_0]STEPSPACE

setp [HMOT](CARD0).stepgen.01.position-scale [JOINT_0]STEP_SCALE

setp [HMOT](CARD0).stepgen.01.step_type 0

setp [HMOT](CARD0).stepgen.01.control-type 1

setp [HMOT](CARD0).stepgen.01.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.01.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => [HMOT](CARD0).stepgen.01.velocity-cmd

net x-pos-fb <= [HMOT](CARD0).stepgen.01.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => [HMOT](CARD0).stepgen.01.enable

# ---setup home / limit switch signals---

net both-home-x => joint.0.home-sw-in

net both-home-x => joint.0.neg-lim-sw-in

net both-home-x => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.03.dirsetup [JOINT_1]DIRSETUP

setp [HMOT](CARD0).stepgen.03.dirhold [JOINT_1]DIRHOLD

setp [HMOT](CARD0).stepgen.03.steplen [JOINT_1]STEPLEN

setp [HMOT](CARD0).stepgen.03.stepspace [JOINT_1]STEPSPACE

setp [HMOT](CARD0).stepgen.03.position-scale [JOINT_1]STEP_SCALE

setp [HMOT](CARD0).stepgen.03.step_type 0

setp [HMOT](CARD0).stepgen.03.control-type 1

setp [HMOT](CARD0).stepgen.03.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.03.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => [HMOT](CARD0).stepgen.03.velocity-cmd

net y-pos-fb <= [HMOT](CARD0).stepgen.03.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => [HMOT](CARD0).stepgen.03.enable

# ---setup home / limit switch signals---

net both-home-y => joint.1.home-sw-in

net both-home-y => joint.1.neg-lim-sw-in

net both-home-y => joint.1.pos-lim-sw-in

#*******************

# Tandem AXIS Y2 JOINT 2

#*******************

setp pid.y2.Pgain [JOINT_2]P

setp pid.y2.Igain [JOINT_2]I

setp pid.y2.Dgain [JOINT_2]D

setp pid.y2.bias [JOINT_2]BIAS

setp pid.y2.FF0 [JOINT_2]FF0

setp pid.y2.FF1 [JOINT_2]FF1

setp pid.y2.FF2 [JOINT_2]FF2

setp pid.y2.deadband [JOINT_2]DEADBAND

setp pid.y2.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.y2.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y2.maxerror 0.012700

net y2-index-enable => pid.y2.index-enable

net y2-enable => pid.y2.enable

net y2-pos-cmd => pid.y2.command

net y2-pos-fb => pid.y2.feedback

net y2-output <= pid.y2.output

# Step Gen signals/setup for tandem axis

setp [HMOT](CARD0).stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp [HMOT](CARD0).stepgen.02.dirhold [JOINT_2]DIRHOLD

setp [HMOT](CARD0).stepgen.02.steplen [JOINT_2]STEPLEN

setp [HMOT](CARD0).stepgen.02.stepspace [JOINT_2]STEPSPACE

setp [HMOT](CARD0).stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp [HMOT](CARD0).stepgen.02.step_type 0

setp [HMOT](CARD0).stepgen.02.control-type 1

setp [HMOT](CARD0).stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y2-pos-cmd <= joint.2.motor-pos-cmd

net y2-vel-cmd <= joint.2.vel-cmd

net y2-output => [HMOT](CARD0).stepgen.02.velocity-cmd

net y2-pos-fb <= [HMOT](CARD0).stepgen.02.position-fb

net y2-pos-fb => joint.2.motor-pos-fb

net y2-enable <= joint.2.amp-enable-out

net y2-enable => [HMOT](CARD0).stepgen.02.enable

# ---setup home / limit switch signals---

net both-home-y2 => joint.2.home-sw-in

net both-home-y2 => joint.2.neg-lim-sw-in

net both-home-y2 => joint.2.pos-lim-sw-in

#*******************

# AXIS Z JOINT 3

#*******************

setp pid.z.Pgain [JOINT_3]P

setp pid.z.Igain [JOINT_3]I

setp pid.z.Dgain [JOINT_3]D

setp pid.z.bias [JOINT_3]BIAS

setp pid.z.FF0 [JOINT_3]FF0

setp pid.z.FF1 [JOINT_3]FF1

setp pid.z.FF2 [JOINT_3]FF2

setp pid.z.deadband [JOINT_3]DEADBAND

setp pid.z.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.00.dirsetup [JOINT_3]DIRSETUP

setp [HMOT](CARD0).stepgen.00.dirhold [JOINT_3]DIRHOLD

setp [HMOT](CARD0).stepgen.00.steplen [JOINT_3]STEPLEN

setp [HMOT](CARD0).stepgen.00.stepspace [JOINT_3]STEPSPACE

setp [HMOT](CARD0).stepgen.00.position-scale [JOINT_3]STEP_SCALE

setp [HMOT](CARD0).stepgen.00.step_type 0

setp [HMOT](CARD0).stepgen.00.control-type 1

setp [HMOT](CARD0).stepgen.00.maxaccel [JOINT_3]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.00.maxvel [JOINT_3]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.3.motor-pos-cmd

net z-vel-cmd <= joint.3.vel-cmd

net z-output => [HMOT](CARD0).stepgen.00.velocity-cmd

net z-pos-fb <= [HMOT](CARD0).stepgen.00.position-fb

net z-pos-fb => joint.3.motor-pos-fb

net z-enable <= joint.3.amp-enable-out

net z-enable => [HMOT](CARD0).stepgen.00.enable

# ---setup home / limit switch signals---

net both-home-z => joint.3.home-sw-in

net both-home-z => joint.3.neg-lim-sw-in

net both-home-z => joint.3.pos-lim-sw-in

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

setp hm2_7i96.0.encoder.00.counter-mode 1

setp hm2_7i96.0.encoder.00.filter 1

setp hm2_7i96.0.encoder.00.scale -1

net plasmac:arc-voltage-in hm2_7i96.0.encoder.00.velocity => plasmac.arc-voltage-in

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---QTPLASMAC TOOLCHANGE PASSTHROUGH---

net tool:change iocontrol.0.tool-change => iocontrol.0.tool-changed

net tool:prep iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

# Include your custom HAL commands here

# This file will not be overwritten when you run PNCconf again

# ---COMMON PLASMAC DEBOUNCE---

# for the float and ohmic inputs each increment in delay is

# is a 0.001mm (0.00004") increase in any probed height result

setp db_float.delay 5

# set to zero if using internal ohmic sensing

setp db_ohmic.delay 0

setp db_breakaway.delay 5

setp db_arc-ok.delay 5

########################################

# The following variables are available for fine tuning some parameters.

# To use any of these, uncomment the required setp line and set an appropriate value.

# Dampen excessive noise on the arc voltage input

# default = 0 (volts)

#setp plasmac.lowpass-frequency 0

# The time delay from losing the arc ok signal until QtPlasmaC reacts to the arc loss.

# default = 0.0 (seconds)

#setp plasmac.arc-lost-delay 0.0

# For mode 0 Arc-OK only, the number of consecutive readings within the threshold that are required to set the Arc-OK signal.

# default = 6

#setp plasmac.arc-ok-counts 6

# For mode 0 Arc-OK only, the maximum voltage deviation that is allowed for a valid voltage to set the Arc OK signal.

#default = 10 (volts)

#setp plasmac.arc-ok-threshold 10

# The voltage above and below 0V that will display as 0V. Prevents small fluctuations from flickering the voltage display.

# default = 0 (volts)

#setp plasmac.zero-window 0

# The distance (in millimeters) away from the Z MAX_LIMIT that QtPlasmaC will allow the Z axis to travel while under machine control.

# default = 5 (mm)

#setp plasmac.max-offset 5

# The required number of consecutive times that the threshold has been exceeded before applying the void lock to the THC.

# default = 2

#setp plasmac.kerf-error-max 2

# ---OHMIC SENSE CONTACT DEBOUNCE---

setp plasmac.ohmic-sense-off-delay 3

setp plasmac.ohmic-sense-on-delay 3

Mesa 7i96,THCAD10, closed loop nema34. hypertherm xp45 with cpc port.

all fixed with the 24v field power. thanks Rod.

next problem is the thc is not reading. I have checked the THC with 9V battery and it works there, so guessing the problem lies in my INI or HAL files.

# Generated by PNCconf at Sun Feb 2 06:15:46 2025

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = T17

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = qtvcp qtplasmac

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/cnc/linuxcnc/nc_files

INCREMENTS = 10mm 1mm 100mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 83.333333

MAX_LINEAR_VELOCITY = 183.333333

MIN_LINEAR_VELOCITY = 1.666667

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

GEOMETRY = xyz

CYCLE_TIME = 100

[FILTER]

PROGRAM_EXTENSION = .ngc,.nc,.tap GCode File (*.ngc, *.nc, *.tap)

ngc = qtplasmac_gcode

nc = qtplasmac_gcode

tap = qtplasmac_gcode

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G21 G40 G49 G80 G90 G92.1 G94 G97 M52P1

SUBROUTINE_PATH = ./:../../nc_files

USER_M_PATH = ./:../../nc_files

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

CARD0=hm2_7i96.0

[HAL]

HALUI = halui

HALFILE = T17.hal

HALFILE = qtplasmac_comp.hal

HALFILE = custom.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 4

KINEMATICS = trivkins coordinates=XYYZ

[TRAJ]

SPINDLES = 3

COORDINATES = XYYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 18.33

MAX_LINEAR_VELOCITY = 183.33

NO_FORCE_HOMING = 1

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

# MAX_VEL & MAX_ACC need to be twice the corresponding joint value

MAX_VELOCITY = 366.6666666666667

MAX_ACCELERATION = 4000.0

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -5.0

MAX_LIMIT = 1300.0

[JOINT_0]

TYPE = LINEAR

HOME = 10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 183.33333333333334

MAX_ACCELERATION = 2000.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 229.17

STEPGEN_MAXACCEL = 2500.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 52.0833

MIN_LIMIT = -5.0

MAX_LIMIT = 1300.0

HOME_OFFSET = -10.000000

HOME_SEARCH_VEL = -50.000000

HOME_LATCH_VEL = -25.000000

HOME_FINAL_VEL = 16.666667

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Y]

# MAX_VEL & MAX_ACC need to be twice the corresponding joint value

MAX_VELOCITY = 366.6666666666667

MAX_ACCELERATION = 5000.0

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -5.0

MAX_LIMIT = 2520.0

[JOINT_1]

TYPE = LINEAR

HOME = 10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 183.33333333333334

MAX_ACCELERATION = 2500.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 229.17

STEPGEN_MAXACCEL = 3125.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 52.0833

MIN_LIMIT = -5.0

MAX_LIMIT = 2520.0

HOME_OFFSET = -10.000000

HOME_SEARCH_VEL = -50.000000

HOME_LATCH_VEL = -25.000000

HOME_FINAL_VEL = 16.666667

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = -2

[JOINT_2]

TYPE = LINEAR

HOME = 10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 183.33333333333334

MAX_ACCELERATION = 2500.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 229.17

STEPGEN_MAXACCEL = 3125.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 52.0833

MIN_LIMIT = -5.0

MAX_LIMIT = 2520.0

HOME_OFFSET = -10.000000

HOME_SEARCH_VEL = -50.000000

HOME_LATCH_VEL = -25.000000

HOME_FINAL_VEL = 16.666667

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = -2

#******************************************

#******************************************

[AXIS_Z]

# MAX_VEL & MAX_ACC need to be twice the corresponding joint value

MAX_VELOCITY = 66.66666666666667

MAX_ACCELERATION = 400.0

OFFSET_AV_RATIO = 0.5

MIN_LIMIT = -150.0

MAX_LIMIT = 5.0

[JOINT_3]

TYPE = LINEAR

HOME = -10.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 33.333333333333336

MAX_ACCELERATION = 200.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 41.67

STEPGEN_MAXACCEL = 250.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 392.1569

MIN_LIMIT = -150.0

MAX_LIMIT = 5.0

HOME_OFFSET = 5.000000

HOME_SEARCH_VEL = 8.333333

HOME_LATCH_VEL = 8.333333

HOME_FINAL_VEL = -8.333333

HOME_USE_INDEX = NO

HOME_IGNORE_LIMITS = YES

HOME_SEQUENCE = 1

#******************************************

# Generated by PNCconf at Sun Jan 26 20:35:25 2025

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS num_spindles=[TRAJ]SPINDLES

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=1 num_pwmgens=0 num_stepgens=5 sserial_port_0=0xxxxxxx"

setp [HMOT](CARD0).watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.y2,pid.z,pid.s

loadrt plasmac

addf [HMOT](CARD0).read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.y2.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf plasmac servo-thread

addf [HMOT](CARD0).write servo-thread

setp [HMOT](CARD0).dpll.01.timer-us -50

setp [HMOT](CARD0).stepgen.timer-number 1

# ---PLASMA INPUT DEBOUNCE---

#values for these are in custom.hal

loadrt dbounce names=db_breakaway,db_float,db_ohmic,db_arc-ok

addf db_float servo-thread

addf db_ohmic servo-thread

addf db_breakaway servo-thread

addf db_arc-ok servo-thread

# ---JOINT ASSOCIATED WITH THE Z AXIS---

net plasmac:axis-position joint.3.pos-fb => plasmac.axis-z-position

# ---PLASMA INPUTS---

# ---all modes---

net plasmac:float-switch => db_float.in

net plasmac:breakaway => db_breakaway.in

net plasmac:ohmic-probe => db_ohmic.in

net plasmac:ohmic-sense-in => plasmac.ohmic-sense-in

# ---modes 0 & 1

net plasmac:arc-voltage-in => plasmac.arc-voltage-in

# ---modes 1 & 2

net plasmac:arc-ok-in => db_arc-ok.in

# ---mode 2

net plasmac:move-up <= plasmac.move-up

net plasmac:move-down <= plasmac.move-down

# ---PLASMA OUTPUTS---

# ---all modes---

net plasmac:ohmic-enable <= plasmac.ohmic-enable

net plasmac:scribe-arm <= plasmac.scribe-arm

net plasmac:scribe-on <= plasmac.scribe-on

# external output signals

# --- PLASMAC:TORCH-ON ---

net plasmac:torch-on => [HMOT](CARD0).ssr.00.out-00

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= [HMOT](CARD0).gpio.000.in_not

# --- BOTH-HOME-X ---

net both-home-x <= [HMOT](CARD0).gpio.001.in_not

# --- BOTH-HOME-Y ---

net both-home-y <= [HMOT](CARD0).gpio.002.in_not

# --- BOTH-HOME-Y2 ---

net both-home-y2 <= [HMOT](CARD0).gpio.003.in_not

# --- BOTH-HOME-Z ---

net both-home-z <= [HMOT](CARD0).gpio.004.in_not

# --- PLASMAC:FLOAT-SWITCH ---

net plasmac:float-switch <= [HMOT](CARD0).gpio.005.in_not

# --- PLASMAC:BREAKAWAY ---

net plasmac:breakaway <= [HMOT](CARD0).gpio.006.in_not

# --- Encoder ---

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.01.dirsetup [JOINT_0]DIRSETUP

setp [HMOT](CARD0).stepgen.01.dirhold [JOINT_0]DIRHOLD

setp [HMOT](CARD0).stepgen.01.steplen [JOINT_0]STEPLEN

setp [HMOT](CARD0).stepgen.01.stepspace [JOINT_0]STEPSPACE

setp [HMOT](CARD0).stepgen.01.position-scale [JOINT_0]STEP_SCALE

setp [HMOT](CARD0).stepgen.01.step_type 0

setp [HMOT](CARD0).stepgen.01.control-type 1

setp [HMOT](CARD0).stepgen.01.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.01.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => [HMOT](CARD0).stepgen.01.velocity-cmd

net x-pos-fb <= [HMOT](CARD0).stepgen.01.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => [HMOT](CARD0).stepgen.01.enable

# ---setup home / limit switch signals---

net both-home-x => joint.0.home-sw-in

net both-home-x => joint.0.neg-lim-sw-in

net both-home-x => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.03.dirsetup [JOINT_1]DIRSETUP

setp [HMOT](CARD0).stepgen.03.dirhold [JOINT_1]DIRHOLD

setp [HMOT](CARD0).stepgen.03.steplen [JOINT_1]STEPLEN

setp [HMOT](CARD0).stepgen.03.stepspace [JOINT_1]STEPSPACE

setp [HMOT](CARD0).stepgen.03.position-scale [JOINT_1]STEP_SCALE

setp [HMOT](CARD0).stepgen.03.step_type 0

setp [HMOT](CARD0).stepgen.03.control-type 1

setp [HMOT](CARD0).stepgen.03.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.03.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => [HMOT](CARD0).stepgen.03.velocity-cmd

net y-pos-fb <= [HMOT](CARD0).stepgen.03.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => [HMOT](CARD0).stepgen.03.enable

# ---setup home / limit switch signals---

net both-home-y => joint.1.home-sw-in

net both-home-y => joint.1.neg-lim-sw-in

net both-home-y => joint.1.pos-lim-sw-in

#*******************

# Tandem AXIS Y2 JOINT 2

#*******************

setp pid.y2.Pgain [JOINT_2]P

setp pid.y2.Igain [JOINT_2]I

setp pid.y2.Dgain [JOINT_2]D

setp pid.y2.bias [JOINT_2]BIAS

setp pid.y2.FF0 [JOINT_2]FF0

setp pid.y2.FF1 [JOINT_2]FF1

setp pid.y2.FF2 [JOINT_2]FF2

setp pid.y2.deadband [JOINT_2]DEADBAND

setp pid.y2.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.y2.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y2.maxerror 0.012700

net y2-index-enable => pid.y2.index-enable

net y2-enable => pid.y2.enable

net y2-pos-cmd => pid.y2.command

net y2-pos-fb => pid.y2.feedback

net y2-output <= pid.y2.output

# Step Gen signals/setup for tandem axis

setp [HMOT](CARD0).stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp [HMOT](CARD0).stepgen.02.dirhold [JOINT_2]DIRHOLD

setp [HMOT](CARD0).stepgen.02.steplen [JOINT_2]STEPLEN

setp [HMOT](CARD0).stepgen.02.stepspace [JOINT_2]STEPSPACE

setp [HMOT](CARD0).stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp [HMOT](CARD0).stepgen.02.step_type 0

setp [HMOT](CARD0).stepgen.02.control-type 1

setp [HMOT](CARD0).stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y2-pos-cmd <= joint.2.motor-pos-cmd

net y2-vel-cmd <= joint.2.vel-cmd

net y2-output => [HMOT](CARD0).stepgen.02.velocity-cmd

net y2-pos-fb <= [HMOT](CARD0).stepgen.02.position-fb

net y2-pos-fb => joint.2.motor-pos-fb

net y2-enable <= joint.2.amp-enable-out

net y2-enable => [HMOT](CARD0).stepgen.02.enable

# ---setup home / limit switch signals---

net both-home-y2 => joint.2.home-sw-in

net both-home-y2 => joint.2.neg-lim-sw-in

net both-home-y2 => joint.2.pos-lim-sw-in

#*******************

# AXIS Z JOINT 3

#*******************

setp pid.z.Pgain [JOINT_3]P

setp pid.z.Igain [JOINT_3]I

setp pid.z.Dgain [JOINT_3]D

setp pid.z.bias [JOINT_3]BIAS

setp pid.z.FF0 [JOINT_3]FF0

setp pid.z.FF1 [JOINT_3]FF1

setp pid.z.FF2 [JOINT_3]FF2

setp pid.z.deadband [JOINT_3]DEADBAND

setp pid.z.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.00.dirsetup [JOINT_3]DIRSETUP

setp [HMOT](CARD0).stepgen.00.dirhold [JOINT_3]DIRHOLD

setp [HMOT](CARD0).stepgen.00.steplen [JOINT_3]STEPLEN

setp [HMOT](CARD0).stepgen.00.stepspace [JOINT_3]STEPSPACE

setp [HMOT](CARD0).stepgen.00.position-scale [JOINT_3]STEP_SCALE

setp [HMOT](CARD0).stepgen.00.step_type 0

setp [HMOT](CARD0).stepgen.00.control-type 1

setp [HMOT](CARD0).stepgen.00.maxaccel [JOINT_3]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.00.maxvel [JOINT_3]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.3.motor-pos-cmd

net z-vel-cmd <= joint.3.vel-cmd

net z-output => [HMOT](CARD0).stepgen.00.velocity-cmd

net z-pos-fb <= [HMOT](CARD0).stepgen.00.position-fb

net z-pos-fb => joint.3.motor-pos-fb

net z-enable <= joint.3.amp-enable-out

net z-enable => [HMOT](CARD0).stepgen.00.enable

# ---setup home / limit switch signals---

net both-home-z => joint.3.home-sw-in

net both-home-z => joint.3.neg-lim-sw-in

net both-home-z => joint.3.pos-lim-sw-in

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

setp hm2_7i96.0.encoder.00.counter-mode 1

setp hm2_7i96.0.encoder.00.filter 1

setp hm2_7i96.0.encoder.00.scale -1

net plasmac:arc-voltage-in hm2_7i96.0.encoder.00.velocity => plasmac.arc-voltage-in

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---QTPLASMAC TOOLCHANGE PASSTHROUGH---

net tool:change iocontrol.0.tool-change => iocontrol.0.tool-changed

net tool:prep iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

# Include your custom HAL commands here

# This file will not be overwritten when you run PNCconf again

# ---COMMON PLASMAC DEBOUNCE---

# for the float and ohmic inputs each increment in delay is

# is a 0.001mm (0.00004") increase in any probed height result

setp db_float.delay 5

# set to zero if using internal ohmic sensing

setp db_ohmic.delay 0

setp db_breakaway.delay 5

setp db_arc-ok.delay 5

########################################

# The following variables are available for fine tuning some parameters.

# To use any of these, uncomment the required setp line and set an appropriate value.

# Dampen excessive noise on the arc voltage input

# default = 0 (volts)

#setp plasmac.lowpass-frequency 0

# The time delay from losing the arc ok signal until QtPlasmaC reacts to the arc loss.

# default = 0.0 (seconds)

#setp plasmac.arc-lost-delay 0.0

# For mode 0 Arc-OK only, the number of consecutive readings within the threshold that are required to set the Arc-OK signal.

# default = 6

#setp plasmac.arc-ok-counts 6

# For mode 0 Arc-OK only, the maximum voltage deviation that is allowed for a valid voltage to set the Arc OK signal.

#default = 10 (volts)

#setp plasmac.arc-ok-threshold 10

# The voltage above and below 0V that will display as 0V. Prevents small fluctuations from flickering the voltage display.

# default = 0 (volts)

#setp plasmac.zero-window 0

# The distance (in millimeters) away from the Z MAX_LIMIT that QtPlasmaC will allow the Z axis to travel while under machine control.

# default = 5 (mm)

#setp plasmac.max-offset 5

# The required number of consecutive times that the threshold has been exceeded before applying the void lock to the THC.

# default = 2

#setp plasmac.kerf-error-max 2

# ---OHMIC SENSE CONTACT DEBOUNCE---

setp plasmac.ohmic-sense-off-delay 3

setp plasmac.ohmic-sense-on-delay 3

- Boogie

- Boogie

01 Feb 2025 23:52 - 01 Feb 2025 23:53

Replied by Boogie on topic The blacksmith's plasma table

The blacksmith's plasma table

Category: Plasma & Laser

Bulls eye, Tommy. It's Polish indeed. His nickname suggested me he's polish. i have the same machine (stahlwerk cut 70p) with machine torch sitting in the box for more than one year now (yes, haven't used it yet:D) and i think it's time to have some fun with it. it's HF pilot machine and i'm trying to figure out how to make it usable in cnc table. Have a bunch of Mesa cards i bought some time ago when i was visiting the States and would be nice to make it all work together. i don't have THCAD though...:/

Time to create page: 0.922 seconds