Search Results (Searched for: THCAD)

- PCW

11 Nov 2024 14:22 - 11 Nov 2024 14:24

- PCW

11 Nov 2024 14:10 - 11 Nov 2024 14:11

Replied by PCW on topic THCAD2 - HF start will kill it?

THCAD2 - HF start will kill it?

Category: Plasma & Laser

- tommylight

11 Nov 2024 13:38

Replied by tommylight on topic THCAD2 - HF start will kill it?

THCAD2 - HF start will kill it?

Category: Plasma & Laser

- stickys

- stickys

11 Nov 2024 12:16

THCAD2 - HF start will kill it? was created by stickys

THCAD2 - HF start will kill it?

Category: Plasma & Laser

- Robbin

- Robbin

11 Nov 2024 09:08

- tommylight

05 Nov 2024 12:15

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- tcbmetalworks

- tcbmetalworks

05 Nov 2024 01:55

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- rodw

04 Nov 2024 21:50

Replied by rodw on topic THCAD selection including ohmic sensing

THCAD selection including ohmic sensing

Category: Plasmac

- grijalvap

04 Nov 2024 21:15

Replied by grijalvap on topic THCAD selection including ohmic sensing

THCAD selection including ohmic sensing

Category: Plasmac

- rodw

04 Nov 2024 19:12

Replied by rodw on topic THCAD selection including ohmic sensing

THCAD selection including ohmic sensing

Category: Plasmac

- grijalvap

04 Nov 2024 17:45 - 04 Nov 2024 17:47

Replied by grijalvap on topic THCAD selection including ohmic sensing

THCAD selection including ohmic sensing

Category: Plasmac

- Creative25

- Creative25

03 Nov 2024 11:34

Replied by Creative25 on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- tommylight

03 Nov 2024 11:31

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- tcbmetalworks

- tcbmetalworks

03 Nov 2024 04:33

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- sin-do-re

- sin-do-re

02 Nov 2024 22:36 - 02 Nov 2024 22:39

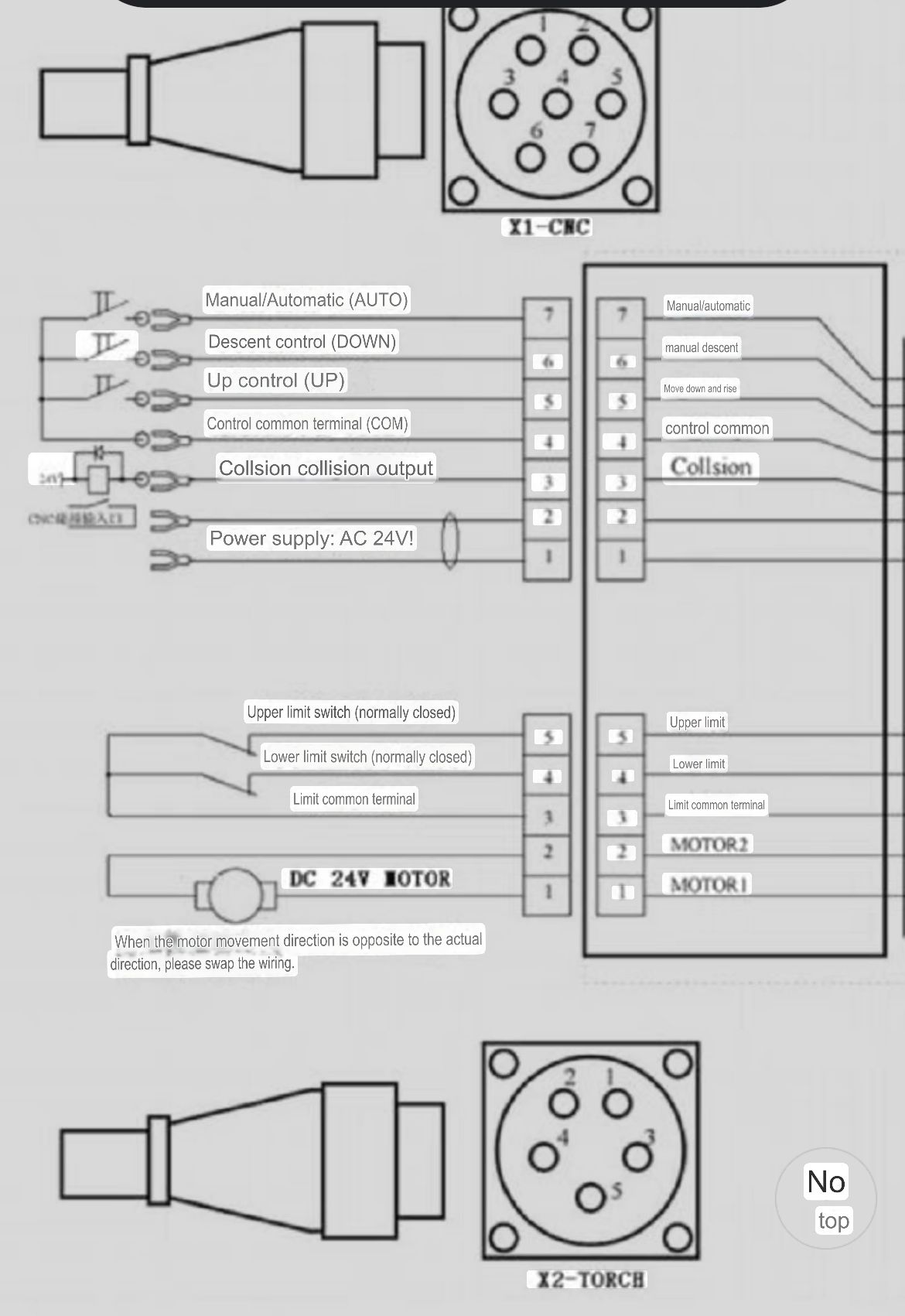

Integrating a CHC-200F Capacitive sensor as a THC was created by sin-do-re

Integrating a CHC-200F Capacitive sensor as a THC

Category: General LinuxCNC Questions

Time to create page: 0.905 seconds