Search Results (Searched for: raspberry pi 3)

- f355

19 Oct 2025 05:41

- unknown

- unknown

18 Oct 2025 23:15

- f355

18 Oct 2025 13:29

- meister

- meister

18 Oct 2025 12:19

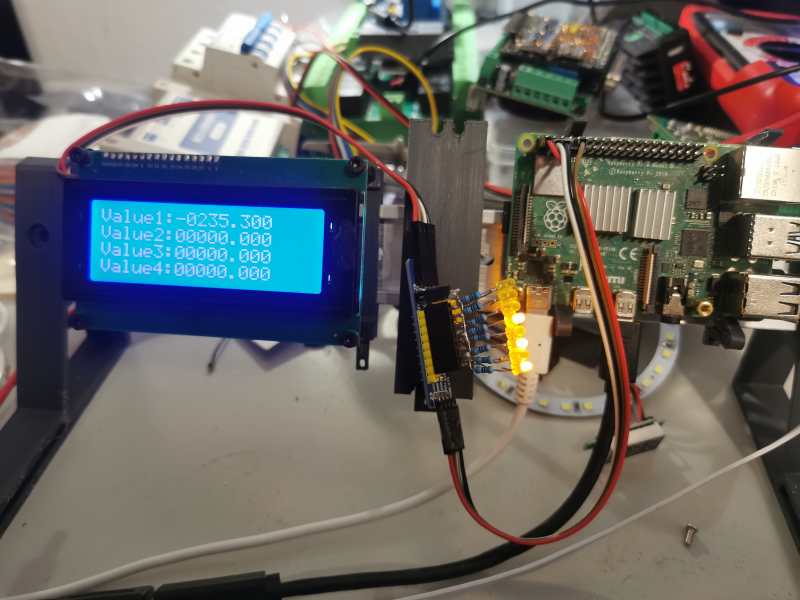

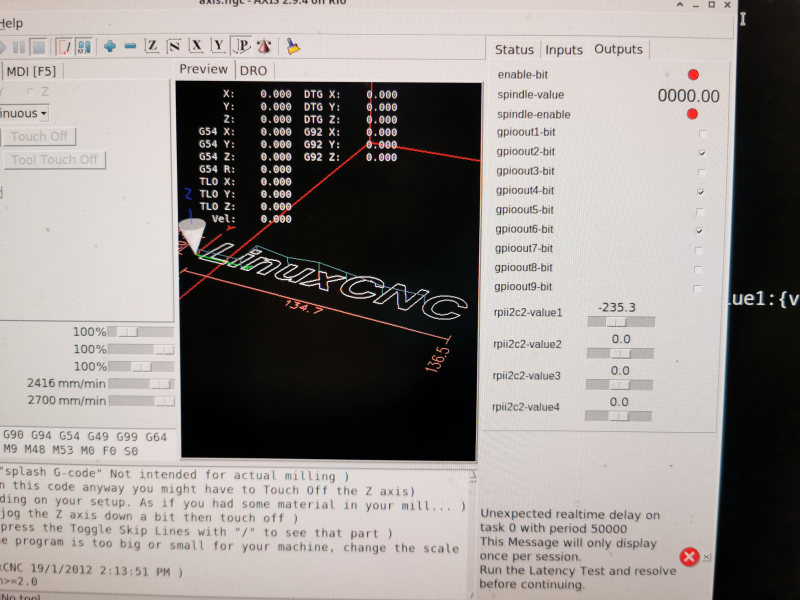

Raspberry PI4/5 I2C support for non realtime IO/ADC/LCD was created by meister

Raspberry PI4/5 I2C support for non realtime IO/ADC/LCD

Category: General LinuxCNC Questions

- unknown

- unknown

18 Oct 2025 10:49 - 16 Nov 2025 02:58

- unknown

- unknown

18 Oct 2025 08:42

Replied by unknown on topic Update LinuxCNC 2.9.5 on debian 13

Update LinuxCNC 2.9.5 on debian 13

Category: Installing LinuxCNC

- f355

18 Oct 2025 05:54

Replied by f355 on topic Update LinuxCNC 2.9.5 on debian 13

Update LinuxCNC 2.9.5 on debian 13

Category: Installing LinuxCNC

- f355

17 Oct 2025 23:11

Replied by f355 on topic Update LinuxCNC 2.9.5 on debian 13

Update LinuxCNC 2.9.5 on debian 13

Category: Installing LinuxCNC

- f355

17 Oct 2025 20:48

Replied by f355 on topic Update LinuxCNC 2.9.5 on debian 13

Update LinuxCNC 2.9.5 on debian 13

Category: Installing LinuxCNC

- unknown

- unknown

17 Oct 2025 20:23

Replied by unknown on topic Update LinuxCNC 2.9.5 on debian 13

Update LinuxCNC 2.9.5 on debian 13

Category: Installing LinuxCNC

- f355

17 Oct 2025 18:25

Replied by f355 on topic Update LinuxCNC 2.9.5 on debian 13

Update LinuxCNC 2.9.5 on debian 13

Category: Installing LinuxCNC

- unknown

- unknown

14 Oct 2025 06:19

Replied by unknown on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- Ul

- Ul

13 Oct 2025 18:22 - 13 Oct 2025 18:36

Replied by Ul on topic Tipps für aktuelle LinuxCNC Hardware gesucht

Tipps für aktuelle LinuxCNC Hardware gesucht

Category: Deutsch

- Ul

- Ul

12 Oct 2025 21:31

Replied by Ul on topic Tipps für aktuelle LinuxCNC Hardware gesucht

Tipps für aktuelle LinuxCNC Hardware gesucht

Category: Deutsch

- unknown

- unknown

12 Oct 2025 10:52

Replied by unknown on topic Probleme WIFI Rasperry Pi5 mit 2.9.6

Probleme WIFI Rasperry Pi5 mit 2.9.6

Category: Deutsch

Time to create page: 0.551 seconds