Search Results (Searched for: stepper spindle)

- Will_cnc

- Will_cnc

Today 09:33

Replied by Will_cnc on topic Step By Step Help Needed . EL8 Leadshine to PI 5

Step By Step Help Needed . EL8 Leadshine to PI 5

Category: EtherCAT

Hi JRC,Thanks for sharing your spindle configuration — it was really helpful. I’ve also replaced the original spindle motor with a 1000W servo from StepperOnline, and I’m pleased with how it’s performing so far - machine has its limitations but for aluminium it seems good so far. I’ve nearly completed my enclosures; I just need to install a coolant system and add the chip tray and filtration underneath to separate the swarf properly.I’m running the Probe Basic interface as well, which I find very intuitive and easy to use.I have the ATC fitted to my machine but haven’t configured it yet. Do you have an ATC installed on yours? If so, would you be willing to share your configuration files (INI, HAL, etc.)? That would be a huge help.Also, I’d really appreciate a bit more detail on the cylinders you’re using to counterbalance the spindle weight.I’m currently designing a 3D-printed cover for the ATC and would be happy to share it once it’s finished.Thanks again Will

- mooser

- mooser

07 Feb 2026 14:24

Adding Feed Rate (IPM or IPR) to the lathe screen was created by mooser

Adding Feed Rate (IPM or IPR) to the lathe screen

Category: AXIS

Is there an easy way to get the feed rate to show up on the screen somewhere? (old 2.7x version)

For various reasons (I use some css and when it's working well I'd like to know what combination of rpm and feed it's actually using) I'd like to see the actual feed the z-axis is on my lathe as it cuts whatever given diameter. I've got a add-on panel showing the actual spindle RPM so although not as straight forward there should be a way of showing the actual FEED of whatever axis. Since somewhere in there should be the pulse rate of the stepper I think it might be available or would I need to have an encoder on that motor/ballscrew and calculate out the feed that way ???

Mooser

For various reasons (I use some css and when it's working well I'd like to know what combination of rpm and feed it's actually using) I'd like to see the actual feed the z-axis is on my lathe as it cuts whatever given diameter. I've got a add-on panel showing the actual spindle RPM so although not as straight forward there should be a way of showing the actual FEED of whatever axis. Since somewhere in there should be the pulse rate of the stepper I think it might be available or would I need to have an encoder on that motor/ballscrew and calculate out the feed that way ???

Mooser

- krille

- krille

02 Feb 2026 18:08

Raspberry pi 5 freze was created by krille

Raspberry pi 5 freze

Category: General LinuxCNC Questions

Hi and so much thanks to the people made all the work with the linuxcnc for raspberry pi 5 ,its a great job.

I have downloaded 4.8.9 and it's a great distro working so fine from beguining and today after a week or two the program stop and freze after 5-10 min. I can still run the stepper from the keyboard and the speedometer on the spindle is i ok and run but the rest of the program stop . the only way to go on is a hard rebot and then it start fine and then the problem starts again . Are there people who can help me in the right direction

I use the byte2bot board in Lathe config. /krister

I have downloaded 4.8.9 and it's a great distro working so fine from beguining and today after a week or two the program stop and freze after 5-10 min. I can still run the stepper from the keyboard and the speedometer on the spindle is i ok and run but the rest of the program stop . the only way to go on is a hard rebot and then it start fine and then the problem starts again . Are there people who can help me in the right direction

I use the byte2bot board in Lathe config. /krister

- zham

- zham

31 Jan 2026 20:28

Need help selecting a Spindle and VFD was created by zham

Need help selecting a Spindle and VFD

Category: Milling Machines

Hi all,

I am completely new to this as you can probably tell. I recently bought an old Gerber Dimension 200 for cheap. It’s a beefy chassis that will allow for a great machine by doing some upgrades. I’m doing a complete overhaul of electronics, spindle, steppers, limit switches etc. All of which will be run off a 7i96 board with the SpinX1. I am a bit confused on how to choose a spindle. I’d like it to integrate with the Mesa board well obviously. The wiring just doesn’t make sense to me on what goes where. If anyone has a solid recommendation for a spindle kit or the like please let me know. Will only be doing wood and aluminum, with the occasional steel sheet. Thank you guys for your time and knowledge.

I am completely new to this as you can probably tell. I recently bought an old Gerber Dimension 200 for cheap. It’s a beefy chassis that will allow for a great machine by doing some upgrades. I’m doing a complete overhaul of electronics, spindle, steppers, limit switches etc. All of which will be run off a 7i96 board with the SpinX1. I am a bit confused on how to choose a spindle. I’d like it to integrate with the Mesa board well obviously. The wiring just doesn’t make sense to me on what goes where. If anyone has a solid recommendation for a spindle kit or the like please let me know. Will only be doing wood and aluminum, with the occasional steel sheet. Thank you guys for your time and knowledge.

- Derriell

- Derriell

28 Jan 2026 01:07 - 28 Jan 2026 02:40

LinuxCNC conversion of Chinese 6040ZH Mach3 router was created by Derriell

LinuxCNC conversion of Chinese 6040ZH Mach3 router

Category: Milling Machines

Hi

I'm new to CNC machines. I want to mill 3D aluminum on a smallish budget. That is the reason why I bough this used machine, my first one. Since I don't want to learn and buy end-of-life software and I like the power and flexibility that comes with open source projects like LinuxCNC the decision to convert it was easy.

It is a Chinese 6040ZH router, 60x40cm bed, 4 axis, rod rails on all axis, 1.5kw spindle, 57BYGH56-4011YD stepper motors (1.26Nm holding torque, 2.8A), 24V system, running mach3 with a USB connection.

Here is a link: www.lygroupchina.com/gantry-cnc-router/h...c-machine-1500w.html

I' ve decided not to invest much into the machine because it has some mechanical design flaws and try to make the best out of it.

Since the controller board runs with a USB-Connection there is no way to run it directly with LinuxCNC. I wanted to know if its possible to reuse the electrical components and it seems so, the stepper motor controllers and the VFD for the spindle. Untested so far.

My plan is to use a MESA i796S board. If you have another suggestion let me know. Unfortunately they are out of stock currently.

The stepper motor controllers are 20 pin modules that stick on some kind of motherboard which also hosts the Mach3 controller, namely a Mach3-R-V1.3. With some reverse engineering I'm confident that I could figure out the function of the pins of the stepper motor controllers. The IC of the drivers seems to be a TB6600HQ or a clone. It has a voltage range of 8-42V, supports operating current of 4.5A, about 150w. It says www.shyidiao.com on them.

Front side from left to right (with the heat spreader remove from the IC. On the bottom left are two optocouplers):

GND, +5V, Pulse, Direction, Stepper RED, Stepper BLUE, Stepper GREEN, Stepper BLACK, +24V, +24V

Back side from left to right (reversed direction from above):

+24V, +24V, Stepper BLACK, Stepper GREEN, Stepper BLUE, Stepper RED, GND, GND, GND, GND

The soldering joints are very likely determining the microstepping of the drivers. If the configuration is from left to right: 1, 1/2, 1/4, 1/8, 1/16 and 1/32 then they are set to a reasonable 1/8.

The spindle driver runs independent of the 24V system. It has two ways to receive an input:

+12V, +5V, i5V (analog Input), SGND (signal ground), FWD (run forward), REV (reverse), BCD2, BCD1, BCD0, ErrB, ErrA

LinuxCNC can handle the TB6600HQ so if its correct they should run with it. Also the spindle can either be run with the analog input or the 3 bit digital one. I still have to decide which one to use. I like the possibility to run the stepper drivers and motors with 36V. That could be a nice upgrade from 24V.

I need a controller board that can handle 4 axis, this VFD, at least one limit switch, touch probe, automatic tool setting and in the future the possibility to attach sensors to close the loop (linear glass scale). The MESA i796S should be able to do that.

A question that is still open to me is how to physically connect the drivers to the MESA board?

Feel free to correct me or give suggestions etc. I hope the MESA cards are back in stock soon.

Bes

I'm new to CNC machines. I want to mill 3D aluminum on a smallish budget. That is the reason why I bough this used machine, my first one. Since I don't want to learn and buy end-of-life software and I like the power and flexibility that comes with open source projects like LinuxCNC the decision to convert it was easy.

It is a Chinese 6040ZH router, 60x40cm bed, 4 axis, rod rails on all axis, 1.5kw spindle, 57BYGH56-4011YD stepper motors (1.26Nm holding torque, 2.8A), 24V system, running mach3 with a USB connection.

Here is a link: www.lygroupchina.com/gantry-cnc-router/h...c-machine-1500w.html

I' ve decided not to invest much into the machine because it has some mechanical design flaws and try to make the best out of it.

- It has rod rails and not linear guides

- The leaver arm on Y-axis to the rod rails is bigger than it needs to be. The rods could have been placed higher

Since the controller board runs with a USB-Connection there is no way to run it directly with LinuxCNC. I wanted to know if its possible to reuse the electrical components and it seems so, the stepper motor controllers and the VFD for the spindle. Untested so far.

My plan is to use a MESA i796S board. If you have another suggestion let me know. Unfortunately they are out of stock currently.

The stepper motor controllers are 20 pin modules that stick on some kind of motherboard which also hosts the Mach3 controller, namely a Mach3-R-V1.3. With some reverse engineering I'm confident that I could figure out the function of the pins of the stepper motor controllers. The IC of the drivers seems to be a TB6600HQ or a clone. It has a voltage range of 8-42V, supports operating current of 4.5A, about 150w. It says www.shyidiao.com on them.

Front side from left to right (with the heat spreader remove from the IC. On the bottom left are two optocouplers):

GND, +5V, Pulse, Direction, Stepper RED, Stepper BLUE, Stepper GREEN, Stepper BLACK, +24V, +24V

Back side from left to right (reversed direction from above):

+24V, +24V, Stepper BLACK, Stepper GREEN, Stepper BLUE, Stepper RED, GND, GND, GND, GND

The soldering joints are very likely determining the microstepping of the drivers. If the configuration is from left to right: 1, 1/2, 1/4, 1/8, 1/16 and 1/32 then they are set to a reasonable 1/8.

The spindle driver runs independent of the 24V system. It has two ways to receive an input:

- an analog input with voltage range 0-5V, currently wired to a potentiometer to manually control the spindle

- three digital inputs, allowing for 8 fixed speeds

+12V, +5V, i5V (analog Input), SGND (signal ground), FWD (run forward), REV (reverse), BCD2, BCD1, BCD0, ErrB, ErrA

LinuxCNC can handle the TB6600HQ so if its correct they should run with it. Also the spindle can either be run with the analog input or the 3 bit digital one. I still have to decide which one to use. I like the possibility to run the stepper drivers and motors with 36V. That could be a nice upgrade from 24V.

I need a controller board that can handle 4 axis, this VFD, at least one limit switch, touch probe, automatic tool setting and in the future the possibility to attach sensors to close the loop (linear glass scale). The MESA i796S should be able to do that.

A question that is still open to me is how to physically connect the drivers to the MESA board?

- Buy these 20 Pin sockets and make a board with them? Probably costly and time consuming

- Solder the connections directly to the pins on the module and attach them somehow. Dirty, easy, quick, downside is, I can't plug them back in the motherboard

- Solder the connecting wires to the motherboard and plug the drivers into the board. Could be neat because the machine could be back ported to Mach3. Possible unwanted side effects on the board. Of course I would unplug the Mach3 controller chip.

Feel free to correct me or give suggestions etc. I hope the MESA cards are back in stock soon.

Bes

- Mark Kraus

- Mark Kraus

26 Jan 2026 21:40

Having Trouble getting encoder to work. Amt102-v 5 wire was created by Mark Kraus

Having Trouble getting encoder to work. Amt102-v 5 wire

Category: Basic Configuration

I was wondering if someone could take a look at my hal and ini files and tell me why i have not encoder count on my halshow but the at speed light is green. All of this worked in uccnc before i switched over. I set the encoder to 1024 ppr. I have 5volts going to encoder.

# Generated by PNCconf at Mon Jan 26 15:37:21 2026

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=1 num_pwmgens=1 num_stepgens=5 sserial_port_0=0xxxxxxx"

setp hm2_7i96s.0.pwmgen.pwm_frequency 5000

setp hm2_7i96s.0.pwmgen.pdm_frequency 6000000

setp hm2_7i96s.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt near

addf hm2_7i96s.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf near.0 servo-thread

addf hm2_7i96s.0.write servo-thread

setp hm2_7i96s.0.dpll.01.timer-us -50

setp hm2_7i96s.0.stepgen.timer-number 1

# external output signals

# --- SPINDLE-BRAKE ---

net spindle-brake => hm2_7i96s.0.ssr.00.out-00

# --- COOLANT-MIST ---

net coolant-mist => hm2_7i96s.0.ssr.00.out-01

# --- SPINDLE-CW ---

net spindle-cw => hm2_7i96s.0.outm.00.out-04

# --- SPINDLE-CCW ---

net spindle-ccw => hm2_7i96s.0.outm.00.out-05

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i96s.0.inm.00.input-00

# --- ALL-LIMIT ---

net all-limit <= hm2_7i96s.0.inm.00.input-01

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.000500

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i96s.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i96s.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i96s.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i96s.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i96s.0.stepgen.00.step_type 0

setp hm2_7i96s.0.stepgen.00.control-type 1

setp hm2_7i96s.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i96s.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i96s.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i96s.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net all-limit => joint.0.neg-lim-sw-in

net all-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.000500

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i96s.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i96s.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i96s.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i96s.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i96s.0.stepgen.01.step_type 0

setp hm2_7i96s.0.stepgen.01.control-type 1

setp hm2_7i96s.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => hm2_7i96s.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_7i96s.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_7i96s.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net all-limit => joint.1.neg-lim-sw-in

net all-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.000500

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i96s.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_7i96s.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_7i96s.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_7i96s.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i96s.0.stepgen.02.step_type 0

setp hm2_7i96s.0.stepgen.02.control-type 1

setp hm2_7i96s.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output => hm2_7i96s.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_7i96s.0.stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_7i96s.0.stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net all-limit => joint.2.neg-lim-sw-in

net all-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---PWM Generator signals/setup---

setp hm2_7i96s.0.pwmgen.00.output-type 1

setp hm2_7i96s.0.pwmgen.00.scale [SPINDLE_0]OUTPUT_SCALE

net spindle-output => hm2_7i96s.0.pwmgen.00.value

net spindle-enable => hm2_7i96s.0.pwmgen.00.enable

# ---Encoder feedback signals/setup---

setp hm2_7i96s.0.encoder.00.counter-mode 0

setp hm2_7i96s.0.encoder.00.filter 1

setp hm2_7i96s.0.encoder.00.index-invert 0

setp hm2_7i96s.0.encoder.00.index-mask 0

setp hm2_7i96s.0.encoder.00.index-mask-invert 0

setp hm2_7i96s.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= hm2_7i96s.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i96s.0.encoder.00.velocity

net spindle-vel-fb-rpm <= hm2_7i96s.0.encoder.00.velocity-rpm

net spindle-index-enable <=> hm2_7i96s.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 1.666667

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

# Generated by PNCconf at Mon Jan 26 15:37:21 2026

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = Bridgeportsimple2

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = qtvcp qtdragon

PREFERENCE_FILE_PATH = WORKINGFOLDER/qtdragon.pref

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_0_OVERRIDE = 2.000000

MIN_SPINDLE_0_OVERRIDE = 0.500000

DEFAULT_SPINDLE_0_SPEED = 500

MIN_SPINDLE_0_SPEED = 100

MAX_SPINDLE_0_SPEED = 2500

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/debian/linuxcnc/nc_files

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 1.000000

MIN_LINEAR_VELOCITY = 0.016670

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

CYCLE_TIME = 100

[MDI_COMMAND_LIST]

MDI_COMMAND = G0 Z0;X0 Y0

MDI_COMMAND = G53 G0 Z0;G53 G0 X0 Y0

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G20 G40 G90 G94 G97 G64 P0.001

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1200000

[HMOT]

# **** This is for info only ****

CARD0=hm2_7i96s.0

[HAL]

HALUI = halui

HALFILE = Bridgeportsimple2.hal

HALFILE = custom.hal

POSTGUI_HALFILE = qtvcp_postgui.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 0.15

MAX_LINEAR_VELOCITY = 1.48

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 1.1666666666666667

MAX_ACCELERATION = 10.0

MIN_LIMIT = -7.0

MAX_LIMIT = 8.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 1.1666666666666667

MAX_ACCELERATION = 10.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 2.33

STEPGEN_MAXACCEL = 20.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 5000

DIRHOLD = 5000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 4000.0

BACKLASH = 0.001

MIN_LIMIT = -7.0

MAX_LIMIT = 8.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 10.0

MIN_LIMIT = -8.0

MAX_LIMIT = 8.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 10.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 2.00

STEPGEN_MAXACCEL = 20.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 5000

DIRHOLD = 5000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = -16000.0

BACKLASH = 0.001

MIN_LIMIT = -8.0

MAX_LIMIT = 8.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 1.4833333333333334

MAX_ACCELERATION = 10.0

MIN_LIMIT = -3.0

MAX_LIMIT = 5.0

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 1.4833333333333334

MAX_ACCELERATION = 10.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 2.97

STEPGEN_MAXACCEL = 20.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 2000

DIRHOLD = 2000

STEPLEN = 2000

STEPSPACE = 2000

STEP_SCALE = -65000.0

BACKLASH = 0.001

MIN_LIMIT = -3.0

MAX_LIMIT = 5.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 1

#******************************************

[SPINDLE_0]

P = 0.0

I = 0.0

D = 0.0

FF0 = 1.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 2000.0

ENCODER_SCALE = 4096.0

OUTPUT_SCALE = 2000

OUTPUT_MIN_LIMIT = -2000

OUTPUT_MAX_LIMIT = 2000

# Include your custom HAL commands here

# This file will not be overwritten when you run PNCconf again

# Custom spindle analog PWM setup for 7i96S TB2 (pot replacement mode)

# This file will not be overwritten when you run PNCconf again

setp hm2_7i96s.0.pwmgen.00.scale 3500 # Max RPM = full ~10V output

# Let pncconf's existing connection handle the value signal

# (it usually connects pwmgen.00.value to spindle-output or similar)

# Enable the PWMgen when spindle is on

#net spindle-on spindle.0.on => hm2_7i96s.0.pwmgen.00.enable

# Optional: Digital FWD enable on TB3 (OUT4 for example)

# net spindle-on hm2_7i96s.0.ssr.00.out-04 # Adjust out-04 to match your assignment

# ============================================

# Spindle Encoder RPM Display Fix (Ultimate Final - No Encoder Pin Nets)

# Only setp for encoder config + single bridge net on display side

# Zero duplicate warnings, pncconf-safe

# ============================================

# Encoder configuration (setp only - completely safe)

setp hm2_7i96s.0.encoder.00.counter-mode 0 # Quadrature A/B/Z

setp hm2_7i96s.0.encoder.00.filter 1 # Filter noise/blips

# Scale - CHANGE THIS to your actual PPR × 4

# Test: Spin shaft 1 full turn by hand → count change / 4 = PPR

# Common AMT102-V settings: 400 CPR → 1600, 1000 → 4000, 1024 → 4096

setp hm2_7i96s.0.encoder.00.scale 4096 # ← EDIT THIS LINE !!!

# Optional: Invert A/B if direction is reversed (counts decrease on forward spin)

# setp hm2_7i96s.0.encoder.00.phase-a-invert 1

# setp hm2_7i96s.0.encoder.00.phase-b-invert 1

# Route pncconf's existing velocity signal to QtDragon RPM display pin

# This is the only net - it never touches encoder pins

# net spindle-vel-fb-rpm => spindle.0.speed-in-rpm

# Optional: Extra smoothing to eliminate random blips when stopped

# Uncomment if blips persist after scale fix

# loadrt lowpass

# addf lowpass.0 servo-thread

# setp lowpass.0.gain 0.05 # Lower = smoother (0.01–0.1 range)

# net spindle-velocity-filtered lowpass.0.out => spindle.0.speed-in-rpm

# Generated by PNCconf at Mon Jan 26 15:37:21 2026

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_eth board_ip="10.10.10.10" config="num_encoders=1 num_pwmgens=1 num_stepgens=5 sserial_port_0=0xxxxxxx"

setp hm2_7i96s.0.pwmgen.pwm_frequency 5000

setp hm2_7i96s.0.pwmgen.pdm_frequency 6000000

setp hm2_7i96s.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt near

addf hm2_7i96s.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf near.0 servo-thread

addf hm2_7i96s.0.write servo-thread

setp hm2_7i96s.0.dpll.01.timer-us -50

setp hm2_7i96s.0.stepgen.timer-number 1

# external output signals

# --- SPINDLE-BRAKE ---

net spindle-brake => hm2_7i96s.0.ssr.00.out-00

# --- COOLANT-MIST ---

net coolant-mist => hm2_7i96s.0.ssr.00.out-01

# --- SPINDLE-CW ---

net spindle-cw => hm2_7i96s.0.outm.00.out-04

# --- SPINDLE-CCW ---

net spindle-ccw => hm2_7i96s.0.outm.00.out-05

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= hm2_7i96s.0.inm.00.input-00

# --- ALL-LIMIT ---

net all-limit <= hm2_7i96s.0.inm.00.input-01

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.000500

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_7i96s.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_7i96s.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_7i96s.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_7i96s.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_7i96s.0.stepgen.00.step_type 0

setp hm2_7i96s.0.stepgen.00.control-type 1

setp hm2_7i96s.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => hm2_7i96s.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_7i96s.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_7i96s.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net all-limit => joint.0.neg-lim-sw-in

net all-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.000500

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_7i96s.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_7i96s.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_7i96s.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_7i96s.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_7i96s.0.stepgen.01.step_type 0

setp hm2_7i96s.0.stepgen.01.control-type 1

setp hm2_7i96s.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => hm2_7i96s.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_7i96s.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_7i96s.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net all-limit => joint.1.neg-lim-sw-in

net all-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.000500

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp hm2_7i96s.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_7i96s.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_7i96s.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_7i96s.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_7i96s.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_7i96s.0.stepgen.02.step_type 0

setp hm2_7i96s.0.stepgen.02.control-type 1

setp hm2_7i96s.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_7i96s.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output => hm2_7i96s.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_7i96s.0.stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_7i96s.0.stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net all-limit => joint.2.neg-lim-sw-in

net all-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---PWM Generator signals/setup---

setp hm2_7i96s.0.pwmgen.00.output-type 1

setp hm2_7i96s.0.pwmgen.00.scale [SPINDLE_0]OUTPUT_SCALE

net spindle-output => hm2_7i96s.0.pwmgen.00.value

net spindle-enable => hm2_7i96s.0.pwmgen.00.enable

# ---Encoder feedback signals/setup---

setp hm2_7i96s.0.encoder.00.counter-mode 0

setp hm2_7i96s.0.encoder.00.filter 1

setp hm2_7i96s.0.encoder.00.index-invert 0

setp hm2_7i96s.0.encoder.00.index-mask 0

setp hm2_7i96s.0.encoder.00.index-mask-invert 0

setp hm2_7i96s.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= hm2_7i96s.0.encoder.00.position

net spindle-vel-fb-rps <= hm2_7i96s.0.encoder.00.velocity

net spindle-vel-fb-rpm <= hm2_7i96s.0.encoder.00.velocity-rpm

net spindle-index-enable <=> hm2_7i96s.0.encoder.00.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 1.666667

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

# Generated by PNCconf at Mon Jan 26 15:37:21 2026

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = Bridgeportsimple2

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = qtvcp qtdragon

PREFERENCE_FILE_PATH = WORKINGFOLDER/qtdragon.pref

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_0_OVERRIDE = 2.000000

MIN_SPINDLE_0_OVERRIDE = 0.500000

DEFAULT_SPINDLE_0_SPEED = 500

MIN_SPINDLE_0_SPEED = 100

MAX_SPINDLE_0_SPEED = 2500

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/debian/linuxcnc/nc_files

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 1.000000

MIN_LINEAR_VELOCITY = 0.016670

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

CYCLE_TIME = 100

[MDI_COMMAND_LIST]

MDI_COMMAND = G0 Z0;X0 Y0

MDI_COMMAND = G53 G0 Z0;G53 G0 X0 Y0

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G20 G40 G90 G94 G97 G64 P0.001

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1200000

[HMOT]

# **** This is for info only ****

CARD0=hm2_7i96s.0

[HAL]

HALUI = halui

HALFILE = Bridgeportsimple2.hal

HALFILE = custom.hal

POSTGUI_HALFILE = qtvcp_postgui.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 0.15

MAX_LINEAR_VELOCITY = 1.48

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 1.1666666666666667

MAX_ACCELERATION = 10.0

MIN_LIMIT = -7.0

MAX_LIMIT = 8.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 1.1666666666666667

MAX_ACCELERATION = 10.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 2.33

STEPGEN_MAXACCEL = 20.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 5000

DIRHOLD = 5000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 4000.0

BACKLASH = 0.001

MIN_LIMIT = -7.0

MAX_LIMIT = 8.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 1

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 10.0

MIN_LIMIT = -8.0

MAX_LIMIT = 8.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 1.0

MAX_ACCELERATION = 10.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 2.00

STEPGEN_MAXACCEL = 20.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 5000

DIRHOLD = 5000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = -16000.0

BACKLASH = 0.001

MIN_LIMIT = -8.0

MAX_LIMIT = 8.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 1.4833333333333334

MAX_ACCELERATION = 10.0

MIN_LIMIT = -3.0

MAX_LIMIT = 5.0

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 1.4833333333333334

MAX_ACCELERATION = 10.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 2.97

STEPGEN_MAXACCEL = 20.00

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 2000

DIRHOLD = 2000

STEPLEN = 2000

STEPSPACE = 2000

STEP_SCALE = -65000.0

BACKLASH = 0.001

MIN_LIMIT = -3.0

MAX_LIMIT = 5.0

HOME_OFFSET = 0.0

HOME_SEQUENCE = 1

#******************************************

[SPINDLE_0]

P = 0.0

I = 0.0

D = 0.0

FF0 = 1.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 2000.0

ENCODER_SCALE = 4096.0

OUTPUT_SCALE = 2000

OUTPUT_MIN_LIMIT = -2000

OUTPUT_MAX_LIMIT = 2000

# Include your custom HAL commands here

# This file will not be overwritten when you run PNCconf again

# Custom spindle analog PWM setup for 7i96S TB2 (pot replacement mode)

# This file will not be overwritten when you run PNCconf again

setp hm2_7i96s.0.pwmgen.00.scale 3500 # Max RPM = full ~10V output

# Let pncconf's existing connection handle the value signal

# (it usually connects pwmgen.00.value to spindle-output or similar)

# Enable the PWMgen when spindle is on

#net spindle-on spindle.0.on => hm2_7i96s.0.pwmgen.00.enable

# Optional: Digital FWD enable on TB3 (OUT4 for example)

# net spindle-on hm2_7i96s.0.ssr.00.out-04 # Adjust out-04 to match your assignment

# ============================================

# Spindle Encoder RPM Display Fix (Ultimate Final - No Encoder Pin Nets)

# Only setp for encoder config + single bridge net on display side

# Zero duplicate warnings, pncconf-safe

# ============================================

# Encoder configuration (setp only - completely safe)

setp hm2_7i96s.0.encoder.00.counter-mode 0 # Quadrature A/B/Z

setp hm2_7i96s.0.encoder.00.filter 1 # Filter noise/blips

# Scale - CHANGE THIS to your actual PPR × 4

# Test: Spin shaft 1 full turn by hand → count change / 4 = PPR

# Common AMT102-V settings: 400 CPR → 1600, 1000 → 4000, 1024 → 4096

setp hm2_7i96s.0.encoder.00.scale 4096 # ← EDIT THIS LINE !!!

# Optional: Invert A/B if direction is reversed (counts decrease on forward spin)

# setp hm2_7i96s.0.encoder.00.phase-a-invert 1

# setp hm2_7i96s.0.encoder.00.phase-b-invert 1

# Route pncconf's existing velocity signal to QtDragon RPM display pin

# This is the only net - it never touches encoder pins

# net spindle-vel-fb-rpm => spindle.0.speed-in-rpm

# Optional: Extra smoothing to eliminate random blips when stopped

# Uncomment if blips persist after scale fix

# loadrt lowpass

# addf lowpass.0 servo-thread

# setp lowpass.0.gain 0.05 # Lower = smoother (0.01–0.1 range)

# net spindle-velocity-filtered lowpass.0.out => spindle.0.speed-in-rpm

- Hakan

- Hakan

26 Jan 2026 08:42 - 26 Jan 2026 08:43

Replied by Hakan on topic Lichuan 4 axis stepper need help-

Lichuan 4 axis stepper need help-

Category: EtherCAT

The same thing happens when people switch between csp and pv modes (rotary axis to spindle motor and back),

they have problem with the rotary position feedback. Could there be a general way? Save the position, and later

create an offset to add to the position feedback. Sounds like that could work.

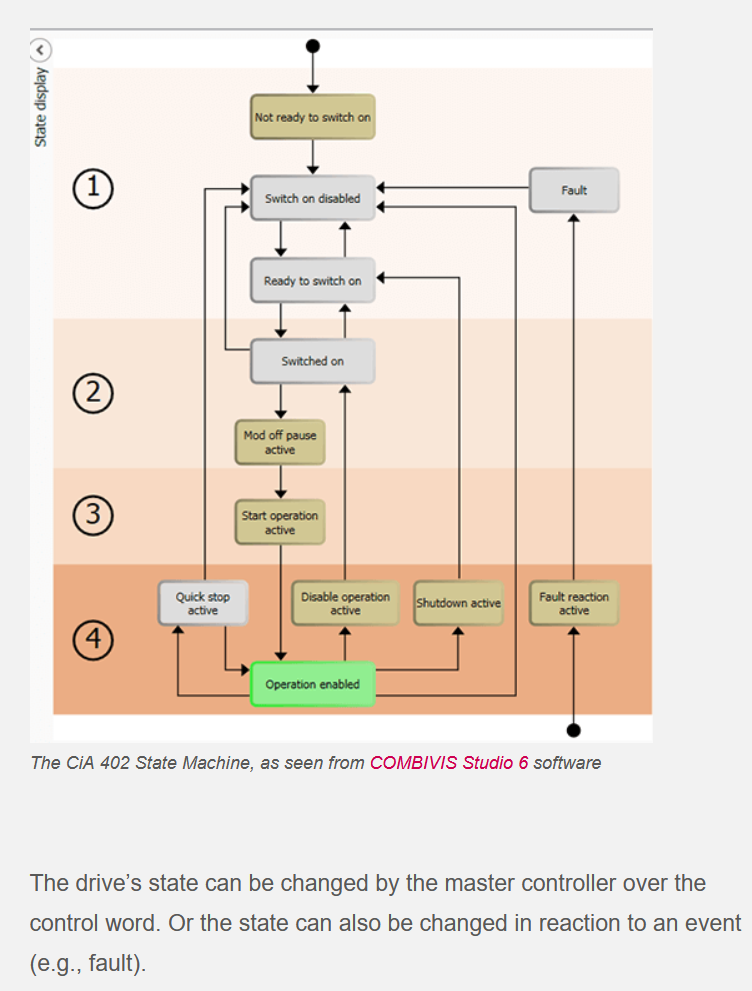

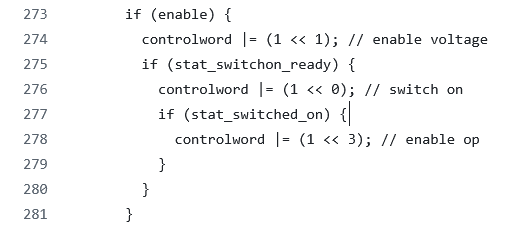

The point I wanted to make about cia402 state machine was that the device decides the state,

the cia402 component can only react and ask for a change of state.

The cia402 component really only uses two states, disabled and op enabled, controlled by the enable pin.

Either transition to and stay in disabled mode, or transition to and stay in op enabled mode.

When in op enabled state, you can switch between the different operation modes. Anyway.

Is there no message in the syslog when you have a mismatch between pdos? I would have expected something there.

they have problem with the rotary position feedback. Could there be a general way? Save the position, and later

create an offset to add to the position feedback. Sounds like that could work.

The point I wanted to make about cia402 state machine was that the device decides the state,

the cia402 component can only react and ask for a change of state.

The cia402 component really only uses two states, disabled and op enabled, controlled by the enable pin.

Either transition to and stay in disabled mode, or transition to and stay in op enabled mode.

When in op enabled state, you can switch between the different operation modes. Anyway.

Is there no message in the syslog when you have a mismatch between pdos? I would have expected something there.

- timo

- timo

25 Jan 2026 14:57 - 25 Jan 2026 15:19

Replied by timo on topic Best controll board for LinuxCNC

Best controll board for LinuxCNC

Category: General LinuxCNC Questions

As I understood open loop drivers and motors are existing and are kept in the system. (for the time beeing)

It is probably difficult to answer the question. What makes a controller better (best)?

It is probably difficult to answer the question. What makes a controller better (best)?

- cheap? (two parallel ports (PCIe cards) in old office PC)

- least amount of re-wiring? (existing parallel port machine?)

- cheaper? (but not a bit of documentation) ( FPGA cards of unknown origin)

- Is wasted time cheaper than money spent?

- easy to set up? ( pnc config)

- upgradable? (linear scales, tool changer, rigid tapping, closed loop positioning, linear motors)

I used an old parallel port machine, changing form mach3 to LinuxCNC was 90% figuring the "charge pump" out (no re-wiring, all in software), then the computer quit service and the replacement had no parallel port. (a 10$ PCIe card fixed that).

Having problems to get an encoder running a Mesa card (6i25 with daughter card) went into the machine. (solving the spindle encoder issue) (it still is a Frankenstein mixed Mesa and Parallel port).

Greetings Timo

p.s. the UC300ETH is that working with linuxcnc? Some older threads stated it does not work.

forum.linuxcnc.org/27-driver-boards/2982...moothstepper-to-mesa

- Hakan

- Hakan

24 Jan 2026 13:16 - 24 Jan 2026 13:18

Replied by Hakan on topic Lichuan 4 axis stepper need help-

Lichuan 4 axis stepper need help-

Category: EtherCAT

Well, I think it follows the state diagram up to the point of operation

But for sure it isn't perfect. I have noticed multiple homing components around even if I don't use it myself.

Can you add support for PV (Profile Velocity) while you are at it? I made a quick fix for that.

PV is suitable for spindle mode.

You should be able to transition states manually, in halshow for example, using controlword and check statusword.

Maybe that can give a clue to why it seems so grumpy.

But for sure it isn't perfect. I have noticed multiple homing components around even if I don't use it myself.

Can you add support for PV (Profile Velocity) while you are at it? I made a quick fix for that.

PV is suitable for spindle mode.

You should be able to transition states manually, in halshow for example, using controlword and check statusword.

Maybe that can give a clue to why it seems so grumpy.

- Mark Kraus

- Mark Kraus

14 Jan 2026 05:29

Trying to move from UCCNC to Linuxcnc and using 7i96s but having trouble was created by Mark Kraus

Trying to move from UCCNC to Linuxcnc and using 7i96s but having trouble

Category: StepConf Wizard

I’m reaching out to the forum to hopefully get some guidance.I’ve spent the past several days working through a LinuxCNC setup with a Mesa 7i96S for what should be a fairly straightforward retrofit on a :Bridgeport Series 2

Mark

- XYZ mill

- X & Y steppers

- Z servo (knee)

- No exotic kinematics, just a basic mill configuration

- I do have solid communication between the PC and the Mesa card

- Network issues are resolved (static IP for Mesa, internet via USB dongle)

- Latency issues were addressed by disabling several BIOS features

- Debian installation and networking are now things I actually understand, which is a win

For context, I’m not new to CNC:Is it realistic to expect a simple XYZ mill (2 steppers + 1 servo) to at least jog without days of trial-and-error, or is this learning curve typical?

- I previously had this machine running under UCCNC

- I had:

- A 4th axis

- VFD spindle control

- Spindle brake

- Mist, air to the knee, and lube pump

- All of that worked reliably

- I want true rigid tapping

- I’m interested in the QtDragon / QtPlasma ecosystem

- I also have a router and another plasma table I’d like to potentially convert

- Installing Debian cleanly

- BIOS tuning for real-time performance

- Static networking for Mesa Ethernet cards

- Separating “GUI motion” from real hardware motion

…but I’m still not confident I understand the correct minimal path to first motion.

- This transition is doable

- There is a clean, recommended workflow for initial bring-up

- I’m not fundamentally missing something obvious

Mark

- jimmyrig

- jimmyrig

06 Jan 2026 04:26

Replied by jimmyrig on topic Complete Newbee - Need help

Complete Newbee - Need help

Category: General LinuxCNC Questions

The way I would approach this (many ways).

First you need to look at the old controller and pray you see a step and direction text somewhere on the board, wire labels, anywhere.

If so follow the below. If not I'd probably see if I could find the software or manual to program the drives. Maybe chapgtp can help here?

If it's step and direction your life is easy

Step 1. Buy a 7i96 or 7i96s, if doing spindle speed control with a vfd S makes it a bit easier. (If you want to check sanity buy a stepper and drive to verify it works before testing the drives)

Step 2. Test the existing servo/stepper drives to see if they work. If you tore apart the wiring this may take some trial and error.

Step 3. Figure out the screw pitch and run through the pnf config

Finally that spindle looks usable...prob the easiest thing to save. Is it a 3 phase induction motor?

First you need to look at the old controller and pray you see a step and direction text somewhere on the board, wire labels, anywhere.

If so follow the below. If not I'd probably see if I could find the software or manual to program the drives. Maybe chapgtp can help here?

If it's step and direction your life is easy

Step 1. Buy a 7i96 or 7i96s, if doing spindle speed control with a vfd S makes it a bit easier. (If you want to check sanity buy a stepper and drive to verify it works before testing the drives)

Step 2. Test the existing servo/stepper drives to see if they work. If you tore apart the wiring this may take some trial and error.

Step 3. Figure out the screw pitch and run through the pnf config

Finally that spindle looks usable...prob the easiest thing to save. Is it a 3 phase induction motor?

- Ozcnc

- Ozcnc

30 Dec 2025 04:15

Replied by Ozcnc on topic Linuxcnc 2.9.7 - Mesa 5i25 with HKD 5 AXIS MACH3 STEPPER I/FACE and 5i25_5ABOBx2

Linuxcnc 2.9.7 - Mesa 5i25 with HKD 5 AXIS MACH3 STEPPER I/FACE and 5i25_5ABOBx2

Category: Driver Boards

Bob has 5v using usb.

I'm only working with 5v now to get step/dir outputs working.

I will connect the 12v supply to run the spindle.

I'm only working with 5v now to get step/dir outputs working.

I will connect the 12v supply to run the spindle.

- Ozcnc

- Ozcnc

29 Dec 2025 12:18

Linuxcnc 2.9.7 - Mesa 5i25 with HKD 5 AXIS MACH3 STEPPER I/FACE and 5i25_5ABOBx2 was created by Ozcnc

Linuxcnc 2.9.7 - Mesa 5i25 with HKD 5 AXIS MACH3 STEPPER I/FACE and 5i25_5ABOBx2

Category: Driver Boards

Hello,

I've spent a few days getting Linuxcnc 2.9.7 up and running with a Mesa 5i25 board, properly flashed and functioning.

My hardware setup consists of 2no X-axis gecko 203V drives, 1no Y - axis, 1no Z-axis, and 1no A-axis.

I have x,y,z home switches, e-stop, and Highspeed Spindle.

I have been trying to get the mesa card to work with a HKD 5 AXIS MACH3 BOB.

Currently i can get mesa to drive the gecko drives and motors if I connect directly (Testing Purposes Only).

I cannot get the HKD BOB to drive the gecko drives and motors.

Does anyone have suggestions?

Thanks,

Orrin

I've spent a few days getting Linuxcnc 2.9.7 up and running with a Mesa 5i25 board, properly flashed and functioning.

My hardware setup consists of 2no X-axis gecko 203V drives, 1no Y - axis, 1no Z-axis, and 1no A-axis.

I have x,y,z home switches, e-stop, and Highspeed Spindle.

I have been trying to get the mesa card to work with a HKD 5 AXIS MACH3 BOB.

Currently i can get mesa to drive the gecko drives and motors if I connect directly (Testing Purposes Only).

I cannot get the HKD BOB to drive the gecko drives and motors.

Does anyone have suggestions?

Thanks,

Orrin

- DoWerna

26 Dec 2025 08:17

CNC Rotary Table with Standalone Controller for Gear Hobbing was created by DoWerna

CNC Rotary Table with Standalone Controller for Gear Hobbing

Category: Basic Configuration

Hello,

I already have a Maho MH500 and a cycloidal lathe retrofitted to LinuxCNC, so I do have some practical experience with LinuxCNC retrofits.Now a colleague has approached me with the following idea:

He wants to build a CNC rotary table for his Maho MH600 in order to hob gears (gear hobbing).The idea is a rotary table with an “electronic gearbox”, synchronized to the machine spindle of the Maho.Key requirements:

I already have a Maho MH500 and a cycloidal lathe retrofitted to LinuxCNC, so I do have some practical experience with LinuxCNC retrofits.Now a colleague has approached me with the following idea:

He wants to build a CNC rotary table for his Maho MH600 in order to hob gears (gear hobbing).The idea is a rotary table with an “electronic gearbox”, synchronized to the machine spindle of the Maho.Key requirements:

- Maximum rotary table speed: ~300 rpm

- Servo or stepper drive with a gearbox, approx. 1:3

- The control should run fully standalone

- Only spindle position and spindle speed are taken from the spindle encoder

- The rotary table is synchronized to the spindle via electronic gearing

- What is the best choice of encoder for this application?

Probably an absolute encoder? or better incremental for a better dynamic? - Servo motor will most likely be NEMA 42 size

- Encoder setup ideas:

- Incremental encoder on the spindle

- Encoder directly on the rotary table

- Possibly an additional encoder on the motor

- How should the control and feedback loops be structured for this setup?

- encoder types and placement

- control loop architecture

- practical LinuxCNC / Mesa hardware solutions for this kind of standalone rotary table

- zippoffs

23 Dec 2025 15:51

DIY CNC Mill - Random Limit Switch Errors was created by zippoffs

DIY CNC Mill - Random Limit Switch Errors

Category: Milling Machines

Hello, I'm new to the forum. I have spent the past year and a half building my own CNC mill that runs on LinuxCNC, and it is mostly done now. Except that I can't get it to finish a program because it keeps thinking that the limit switches have been triggered even though they haven't.

I built this mill from scratch. It is made entirely of aluminum plate and extrusions. It has NEMA23 closed loop steppers, SFU1204 ballscrews, HGH20CA linear rails, a 2.2kw 220v 3 phase spindle and 2.2kw VFD, a "5 axis" parallel port breakout board, a Dell OptiPlex 990 with a parallel port card and running LinuxCNC (obviously). For limit/home switches I have it set up to where one limit switch doubles as a home switch, and all six switches are normally closed and in series all going to one input pin. The limit switches are generic micro switches, and the limit/home switches are Metrol CS067B. I have 24V running through the switches, so I'm using a 24v to 5v optocoupler board to bring the signal down to 5v for the breakout board. The Metrol switch wires are not shielded, but because they cost $67 a piece, I don't want to mess with that. The wires for the other switches are shielded.

This is what happens when I try to run a program: I home the machine, import the program into Axis, hit run, and it could be 1, 5, or 60 seconds later that it suddenly stops the machine because a limit switch was supposedly hit. It doesn't seem to happen consistently. I originally had the VFD next to the other electronics in a copper mesh cage, but ended up making a sheet metal box for it and moving it away (and took the spindle cable out of the cable chain that also held other wires). I thought that would prevent any EMI from interfering with the other electronics. But that didn't fix it. I have narrowed it down to an issue between the spindle/VFD and the breakout board. I can run a program perfectly fine with everything on except for the spindle/VFD, so it can't be the steppers or drivers. I have tried running 24v directly to the optocoupler board, bypassing the switches, but it still triggers. I have tried completely bypassing the limit switch circuit by jumping the input pin on the breakout board to ground, and it still triggers. I have spent hours researching this, and I have tried almost everything. I have my VFD in a Faraday cage. I'm using a shielded spindle cable with the shielding grounded at both ends. I have the signal wires shielded and grounded. I don't know what I'm doing wrong.

I have spent weeks trying to diagnose this, and now I am only more confused. Part of the problem is that I'm only 18 and I'm not an electrical engineer (I'm not even a mechanical engineer yet!), and I'm learning a lot of this for the first time. I have run out of things to try, and I would really appreciate any help I can get. Thank you in advance!

I built this mill from scratch. It is made entirely of aluminum plate and extrusions. It has NEMA23 closed loop steppers, SFU1204 ballscrews, HGH20CA linear rails, a 2.2kw 220v 3 phase spindle and 2.2kw VFD, a "5 axis" parallel port breakout board, a Dell OptiPlex 990 with a parallel port card and running LinuxCNC (obviously). For limit/home switches I have it set up to where one limit switch doubles as a home switch, and all six switches are normally closed and in series all going to one input pin. The limit switches are generic micro switches, and the limit/home switches are Metrol CS067B. I have 24V running through the switches, so I'm using a 24v to 5v optocoupler board to bring the signal down to 5v for the breakout board. The Metrol switch wires are not shielded, but because they cost $67 a piece, I don't want to mess with that. The wires for the other switches are shielded.

This is what happens when I try to run a program: I home the machine, import the program into Axis, hit run, and it could be 1, 5, or 60 seconds later that it suddenly stops the machine because a limit switch was supposedly hit. It doesn't seem to happen consistently. I originally had the VFD next to the other electronics in a copper mesh cage, but ended up making a sheet metal box for it and moving it away (and took the spindle cable out of the cable chain that also held other wires). I thought that would prevent any EMI from interfering with the other electronics. But that didn't fix it. I have narrowed it down to an issue between the spindle/VFD and the breakout board. I can run a program perfectly fine with everything on except for the spindle/VFD, so it can't be the steppers or drivers. I have tried running 24v directly to the optocoupler board, bypassing the switches, but it still triggers. I have tried completely bypassing the limit switch circuit by jumping the input pin on the breakout board to ground, and it still triggers. I have spent hours researching this, and I have tried almost everything. I have my VFD in a Faraday cage. I'm using a shielded spindle cable with the shielding grounded at both ends. I have the signal wires shielded and grounded. I don't know what I'm doing wrong.

I have spent weeks trying to diagnose this, and now I am only more confused. Part of the problem is that I'm only 18 and I'm not an electrical engineer (I'm not even a mechanical engineer yet!), and I'm learning a lot of this for the first time. I have run out of things to try, and I would really appreciate any help I can get. Thank you in advance!

Time to create page: 0.737 seconds