Search Results (Searched for: )

- atrex77

16 Apr 2025 10:01

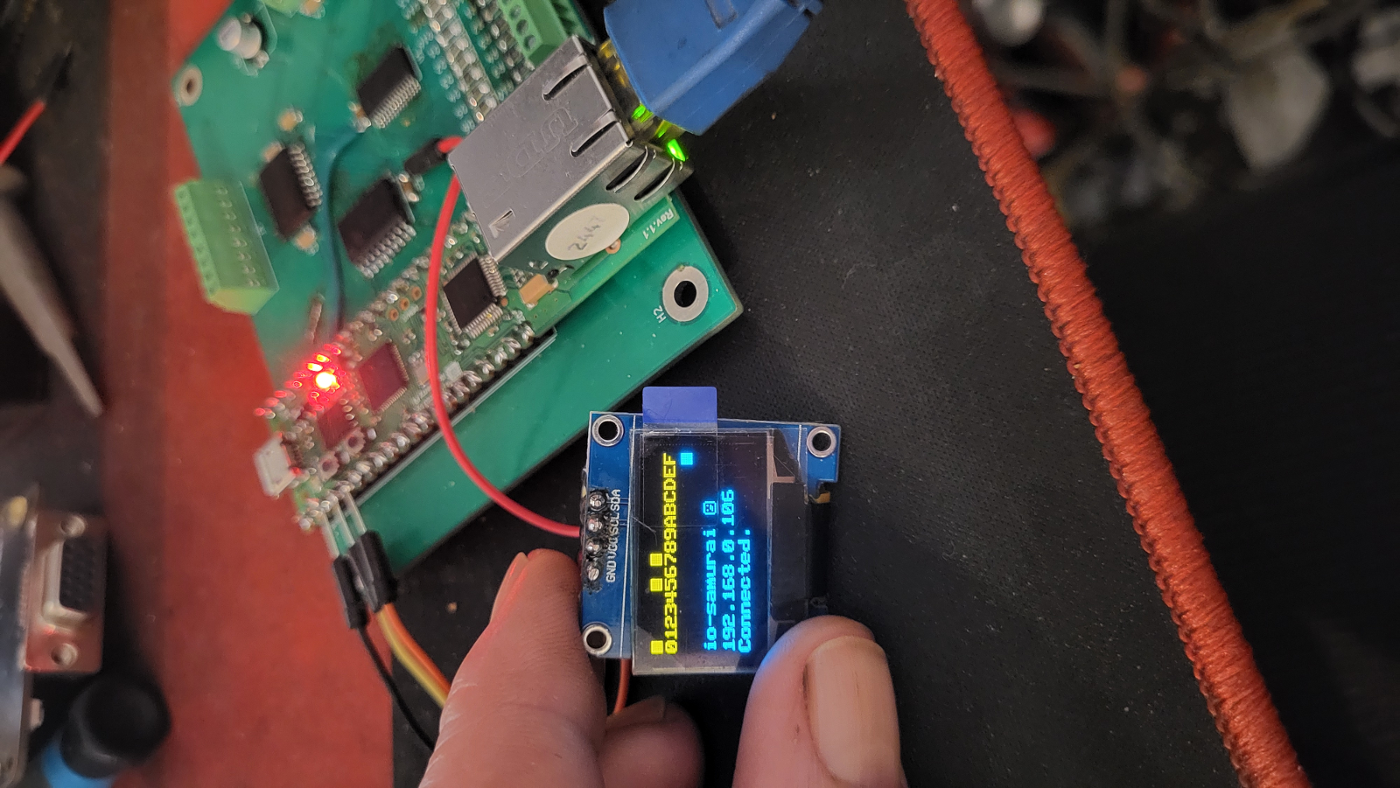

Replied by atrex77 on topic Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Developing a Raspberry Pi Pico-based I/O Board for LinuxCNC

Category: General LinuxCNC Questions

- meister

- meister

16 Apr 2025 09:48

Replied by meister on topic Custom interface board questions

Custom interface board questions

Category: General LinuxCNC Questions

- unknown

- unknown

16 Apr 2025 09:47

Replied by unknown on topic Custom interface board questions

Custom interface board questions

Category: General LinuxCNC Questions

- ajar171

- ajar171

16 Apr 2025 09:43 - 16 Apr 2025 09:46

Replied by ajar171 on topic Custom interface board questions

Custom interface board questions

Category: General LinuxCNC Questions

- tommylight

16 Apr 2025 09:34

Replied by tommylight on topic Custom interface board questions

Custom interface board questions

Category: General LinuxCNC Questions

- ajar171

- ajar171

16 Apr 2025 09:28 - 16 Apr 2025 09:35

Replied by ajar171 on topic Custom interface board questions

Custom interface board questions

Category: General LinuxCNC Questions

- ShemJ

16 Apr 2025 09:20

Replied by ShemJ on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

[ Vfdmod ] An easy VFD control over MODBUS RTU

Category: HAL

- tommylight

16 Apr 2025 09:12

Replied by tommylight on topic Linux_Mint_22.1_LinuxCNC_2.10.iso

Linux_Mint_22.1_LinuxCNC_2.10.iso

Category: Installing LinuxCNC

- meister

- meister

16 Apr 2025 09:10

Replied by meister on topic Custom interface board questions

Custom interface board questions

Category: General LinuxCNC Questions

- tommylight

16 Apr 2025 09:10

Replied by tommylight on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- tommylight

16 Apr 2025 09:02

Replied by tommylight on topic Custom interface board questions

Custom interface board questions

Category: General LinuxCNC Questions

- Grotius

16 Apr 2025 08:02

Replied by Grotius on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- ajar171

- ajar171

16 Apr 2025 07:55 - 16 Apr 2025 08:41

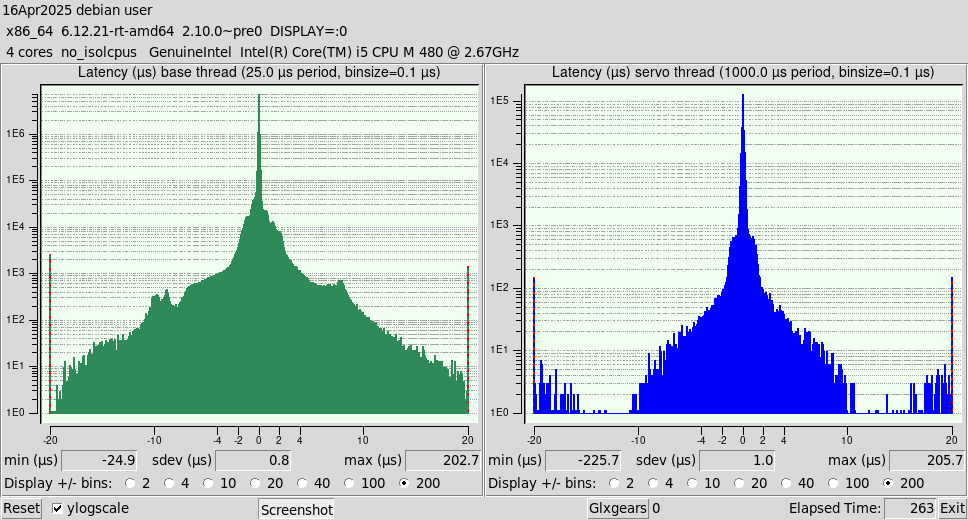

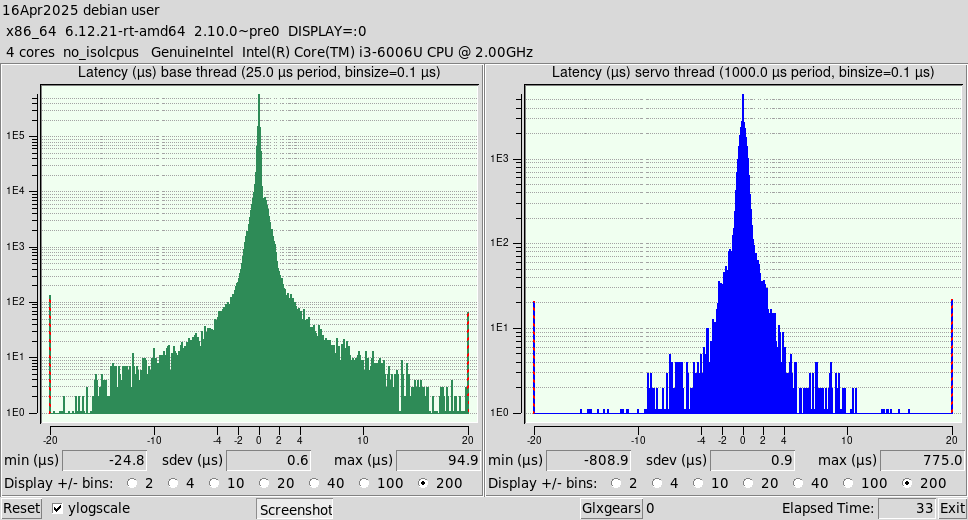

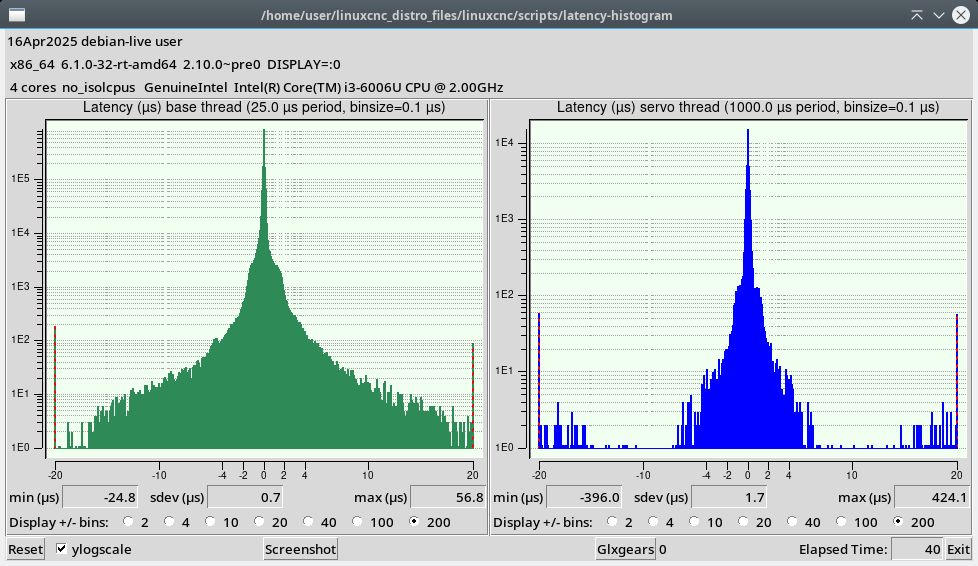

Custom interface board questions was created by ajar171

Custom interface board questions

Category: General LinuxCNC Questions

- Aciera

16 Apr 2025 06:16 - 16 Apr 2025 06:30

Replied by Aciera on topic Remap M6 in python

Remap M6 in python

Category: General LinuxCNC Questions

- unknown

- unknown

16 Apr 2025 05:54

Time to create page: 1.033 seconds