Search Results (Searched for: )

- filipkochan

- filipkochan

12 Apr 2025 17:56

executing subroutines even during import of GCODE file was created by filipkochan

executing subroutines even during import of GCODE file

Category: O Codes (subroutines) and NGCGUI

- israfilcaglar

- israfilcaglar

12 Apr 2025 17:49

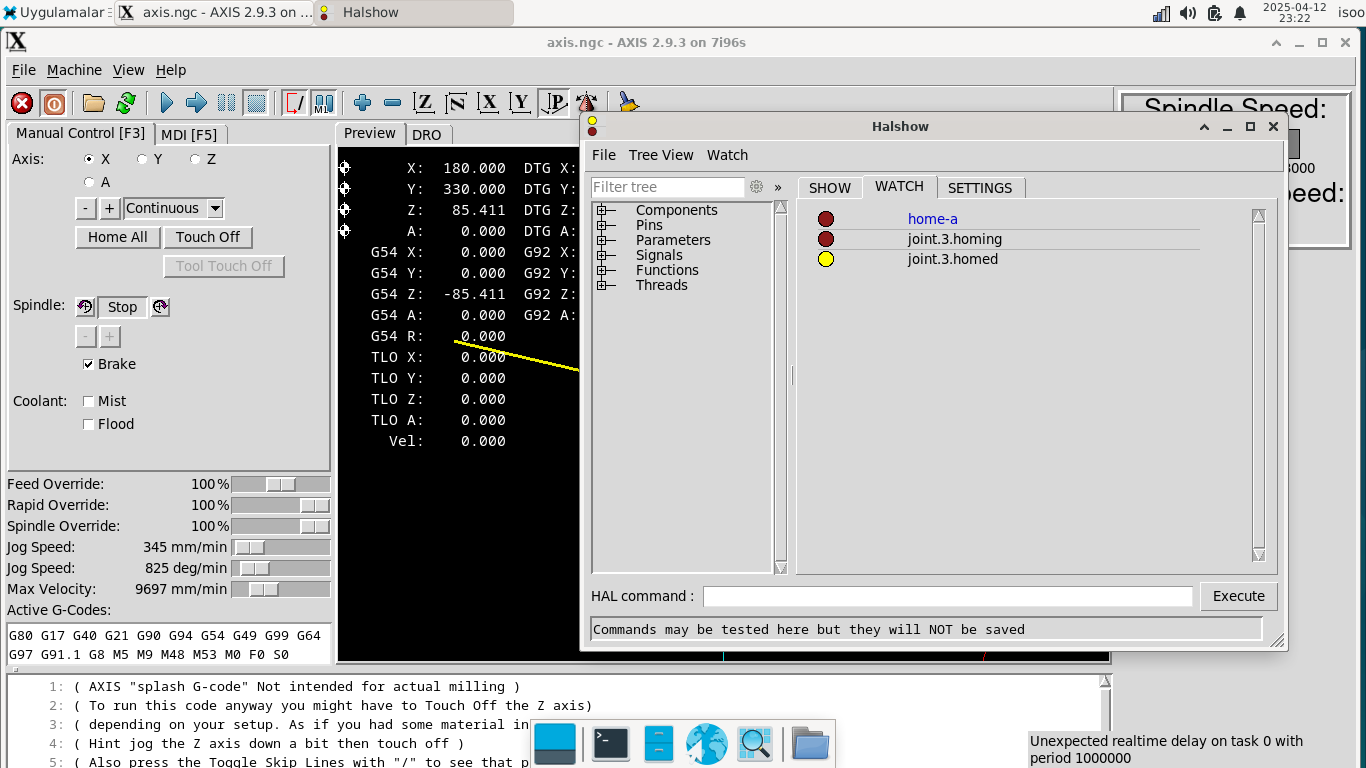

How to homing the A-axis again with gcode? was created by israfilcaglar

How to homing the A-axis again with gcode?

Category: AXIS

- tommylight

12 Apr 2025 17:31

Replied by tommylight on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- PCW

12 Apr 2025 17:24

- MiRu

- MiRu

12 Apr 2025 17:21

- PCW

12 Apr 2025 17:06 - 12 Apr 2025 17:26

- tcbmetalworks

- tcbmetalworks

12 Apr 2025 17:01

Replied by tcbmetalworks on topic 10.5 x 25 cnc plasma table retrofit

10.5 x 25 cnc plasma table retrofit

Category: Computers and Hardware

- PCW

12 Apr 2025 16:50

- ErwinCNC

- ErwinCNC

12 Apr 2025 16:27

- pgf

- pgf

12 Apr 2025 16:19

- PCW

12 Apr 2025 16:15

- Lampje

- Lampje

12 Apr 2025 16:04

- ErwinCNC

- ErwinCNC

12 Apr 2025 15:54

- ErwinCNC

- ErwinCNC

12 Apr 2025 15:50

- PCW

12 Apr 2025 15:03

Time to create page: 0.473 seconds