Search Results (Searched for: )

- tommylight

07 Apr 2025 23:13

Replied by tommylight on topic Free Mesa 5I25 Superport board

Free Mesa 5I25 Superport board

Category: User Exchange

- pgf

- pgf

07 Apr 2025 22:32

Replied by pgf on topic Rotating the g54 coordinate system.

Rotating the g54 coordinate system.

Category: General LinuxCNC Questions

- rodw

07 Apr 2025 22:24

Replied by rodw on topic Spindle control not showing in Axis window...

Spindle control not showing in Axis window...

Category: Basic Configuration

- gmouer

- gmouer

07 Apr 2025 22:03 - 07 Apr 2025 22:05

Replied by gmouer on topic NativeCam on LinuxCNC 2.9.3

NativeCam on LinuxCNC 2.9.3

Category: NativeCAM

- robforbes

- robforbes

07 Apr 2025 21:50 - 08 Apr 2025 18:58

Free Mesa 5I25 Superport board was created by robforbes

Free Mesa 5I25 Superport board

Category: User Exchange

- rodw

07 Apr 2025 21:25

Replied by rodw on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- tommylight

07 Apr 2025 21:22

Replied by tommylight on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- tommylight

07 Apr 2025 21:16

Replied by tommylight on topic How to build a CNC Router?

How to build a CNC Router?

Category: Milling Machines

- Giovanni

- Giovanni

07 Apr 2025 19:05

Replied by Giovanni on topic NativeCam on LinuxCNC 2.9.3

NativeCam on LinuxCNC 2.9.3

Category: NativeCAM

- cakeslob

- cakeslob

07 Apr 2025 19:00

Replied by cakeslob on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- my1987toyota

07 Apr 2025 18:25 - 07 Apr 2025 18:41

Replied by my1987toyota on topic The dumification of humanity through internet

The dumification of humanity through internet

Category: Off Topic and Test Posts

- PCW

07 Apr 2025 17:59

Replied by PCW on topic Joint1 following error

Joint1 following error

Category: General LinuxCNC Questions

- Todd Zuercher

07 Apr 2025 17:17

Replied by Todd Zuercher on topic Joint1 following error

Joint1 following error

Category: General LinuxCNC Questions

- Marc_P

- Marc_P

07 Apr 2025 16:55 - 07 Apr 2025 16:58

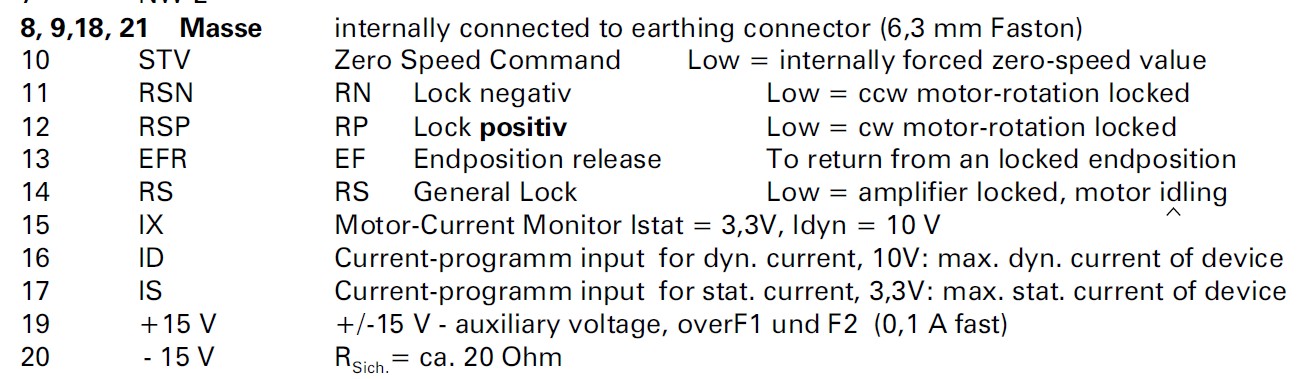

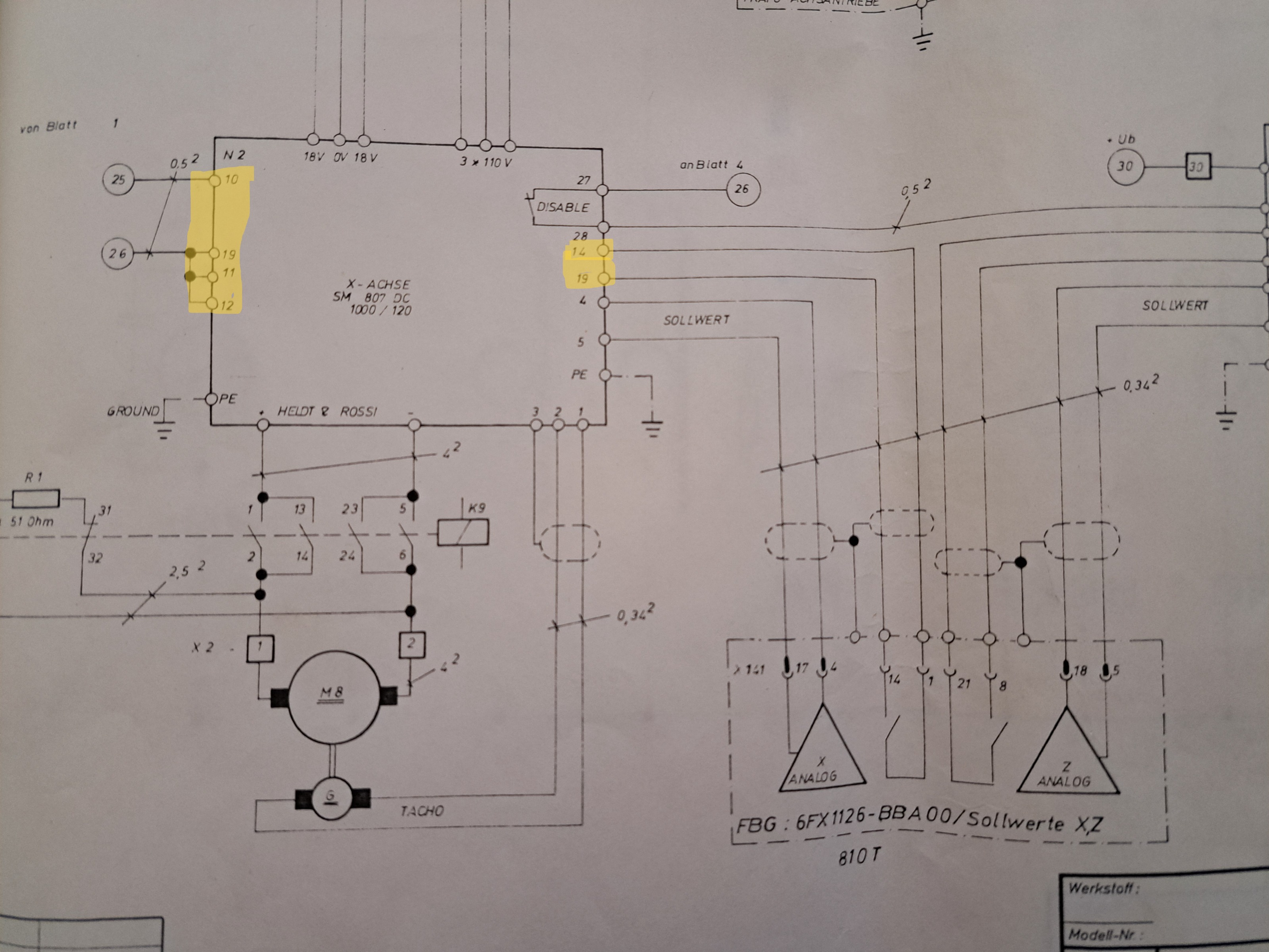

Replied by Marc_P on topic Weiler 160 CNC Retrofit

Weiler 160 CNC Retrofit

Category: Show Your Stuff

- Domi

- Domi

07 Apr 2025 16:47

Replied by Domi on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

Time to create page: 0.451 seconds