Search Results (Searched for: )

- webbyguy

- webbyguy

21 Feb 2025 18:45

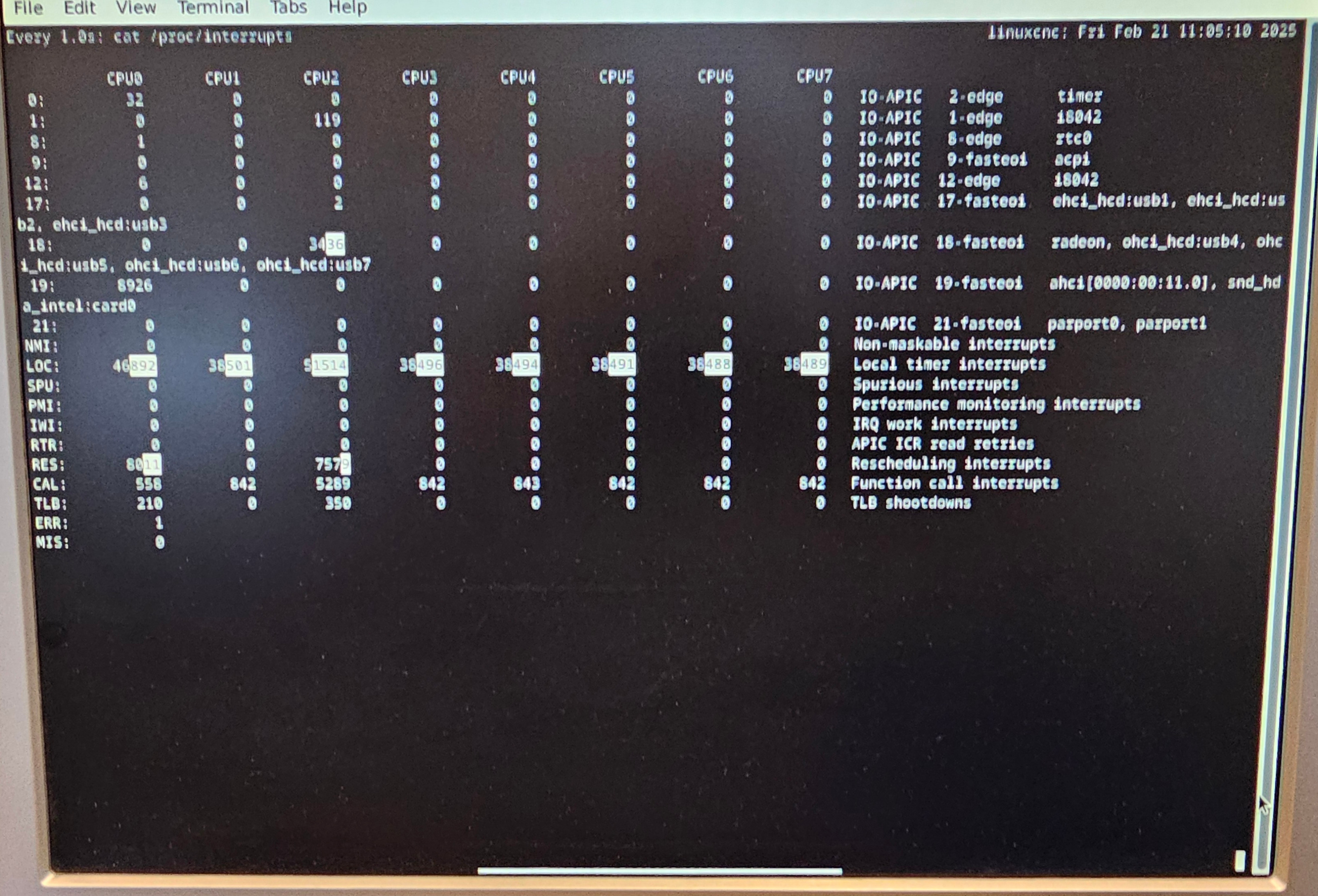

Replied by webbyguy on topic Can't eek out that last bit of jitter

Can't eek out that last bit of jitter

Category: General LinuxCNC Questions

- Sziggy_NC

- Sziggy_NC

21 Feb 2025 17:34

Replied by Sziggy_NC on topic Proof reading please. "unknown control command in o word"

Proof reading please. "unknown control command in o word"

Category: O Codes (subroutines) and NGCGUI

- denhen89

21 Feb 2025 17:06

- Aciera

21 Feb 2025 16:54 - 21 Feb 2025 16:55

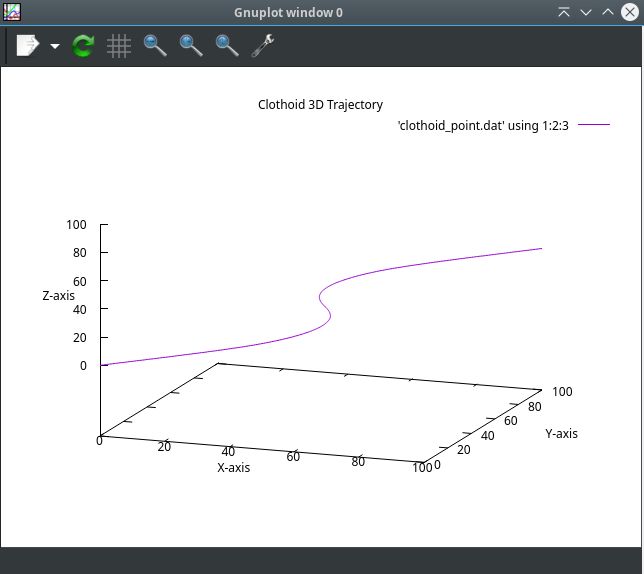

Replied by Aciera on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- tommylight

21 Feb 2025 15:40

Replied by tommylight on topic Elumatec SBZ 130/01 retrofit

Elumatec SBZ 130/01 retrofit

Category: CNC Machines

- Lcvette

21 Feb 2025 15:34

Replied by Lcvette on topic Setting up Probe Basic on my machine questions and issues

Setting up Probe Basic on my machine questions and issues

Category: QtPyVCP

- tommylight

21 Feb 2025 15:18

Replied by tommylight on topic Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Building a 3-axis plasma table with mesa 7i96s, THCad-2 and nema23 steppers

Category: Show Your Stuff

- JuFu

- JuFu

21 Feb 2025 15:12

- tommylight

21 Feb 2025 15:11

Replied by tommylight on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- PCW

21 Feb 2025 15:07 - 21 Feb 2025 15:09

Replied by PCW on topic Mesa 7i97T + 7i84 + 7i78 configuration

Mesa 7i97T + 7i84 + 7i78 configuration

Category: General LinuxCNC Questions

- Grotius

21 Feb 2025 15:03

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- tommylight

21 Feb 2025 14:59 - 21 Feb 2025 15:00

Replied by tommylight on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- PCW

21 Feb 2025 14:57

Replied by PCW on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- PCW

21 Feb 2025 14:48

Replied by PCW on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- FabianB

21 Feb 2025 14:05

Replied by FabianB on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

Time to create page: 0.542 seconds