Search Results (Searched for: )

- notJamesLee

- notJamesLee

16 Jan 2025 04:54

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- dschultz

- dschultz

16 Jan 2025 04:43

Replied by dschultz on topic Missing link in homing LC10E

Missing link in homing LC10E

Category: EtherCAT

- rodw

16 Jan 2025 04:41

Replied by rodw on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- notJamesLee

- notJamesLee

16 Jan 2025 04:06

Replied by notJamesLee on topic First Start Up - E Stops

First Start Up - E Stops

Category: General LinuxCNC Questions

- nawaf

- nawaf

16 Jan 2025 03:51 - 16 Jan 2025 09:34

- nawaf

- nawaf

16 Jan 2025 03:47

- rodw

16 Jan 2025 03:39

- Diel

- Diel

16 Jan 2025 03:24

- Cant do this anymore bye all

16 Jan 2025 02:41

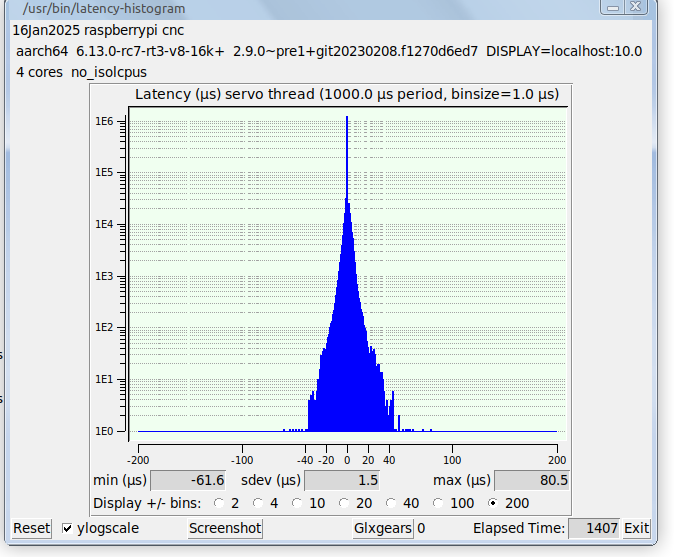

Replied by Cant do this anymore bye all on topic Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Category: Installing LinuxCNC

- arauchfuss

- arauchfuss

16 Jan 2025 02:23 - 16 Jan 2025 02:26

Replied by arauchfuss on topic Tree Journeyman 325 (Dynapath)

Tree Journeyman 325 (Dynapath)

Category: Milling Machines

- vre

- vre

16 Jan 2025 02:23 - 16 Jan 2025 02:24

Replied by vre on topic Mesa modbus and pktUart

Mesa modbus and pktUart

Category: Other User Interfaces

- arauchfuss

- arauchfuss

16 Jan 2025 02:17

Replied by arauchfuss on topic Tree Journeyman 325 (Dynapath)

Tree Journeyman 325 (Dynapath)

Category: Milling Machines

- Cant do this anymore bye all

16 Jan 2025 01:46

Replied by Cant do this anymore bye all on topic Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Category: Installing LinuxCNC

- Cant do this anymore bye all

16 Jan 2025 01:36

Replied by Cant do this anymore bye all on topic Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Category: Installing LinuxCNC

- tommylight

16 Jan 2025 01:24

Replied by tommylight on topic Tree Journeyman 325 (Dynapath)

Tree Journeyman 325 (Dynapath)

Category: Milling Machines

Time to create page: 0.380 seconds