Search Results (Searched for: )

- JT

17 Dec 2024 13:20

- Unlogic

- Unlogic

17 Dec 2024 13:19

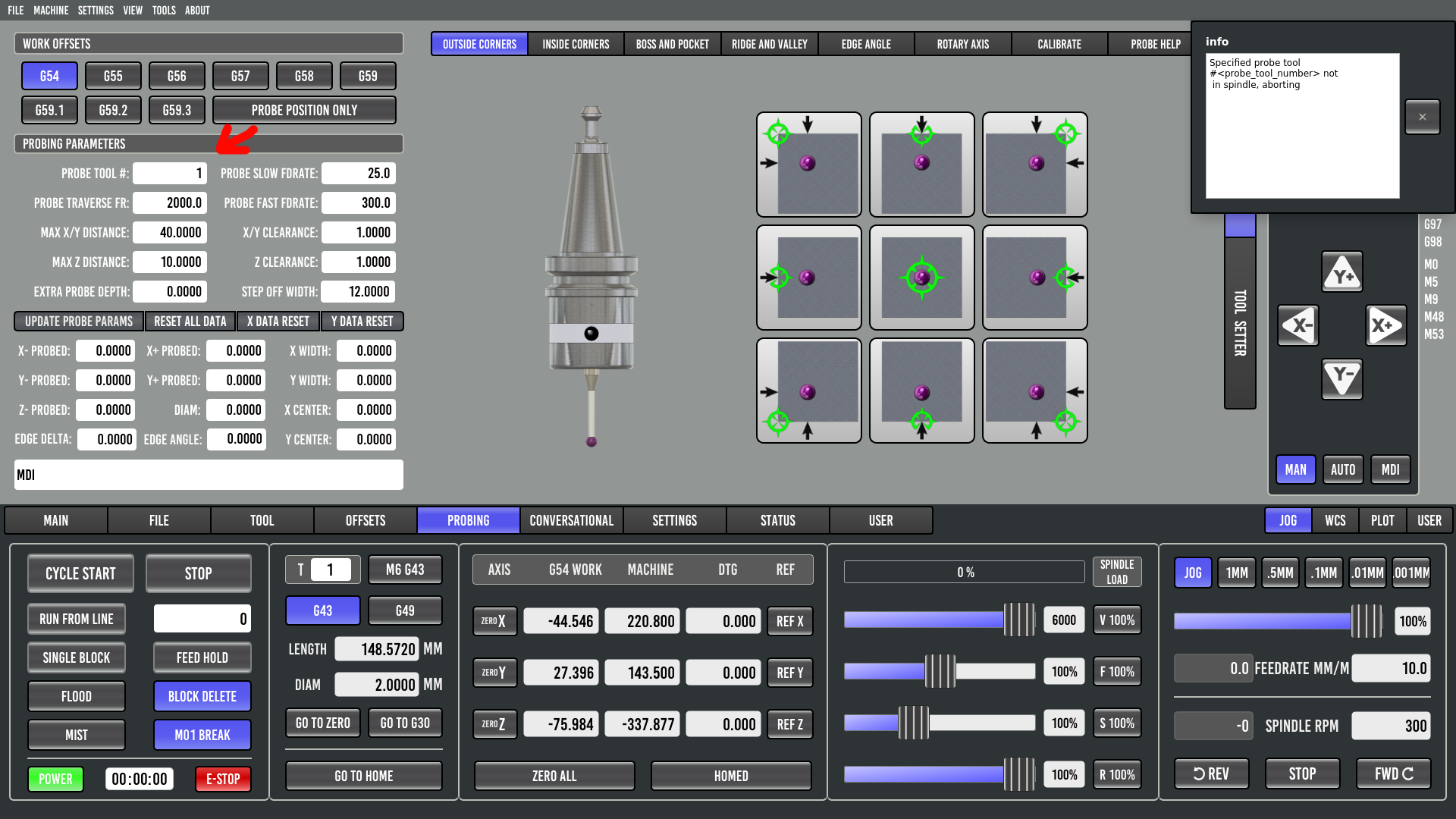

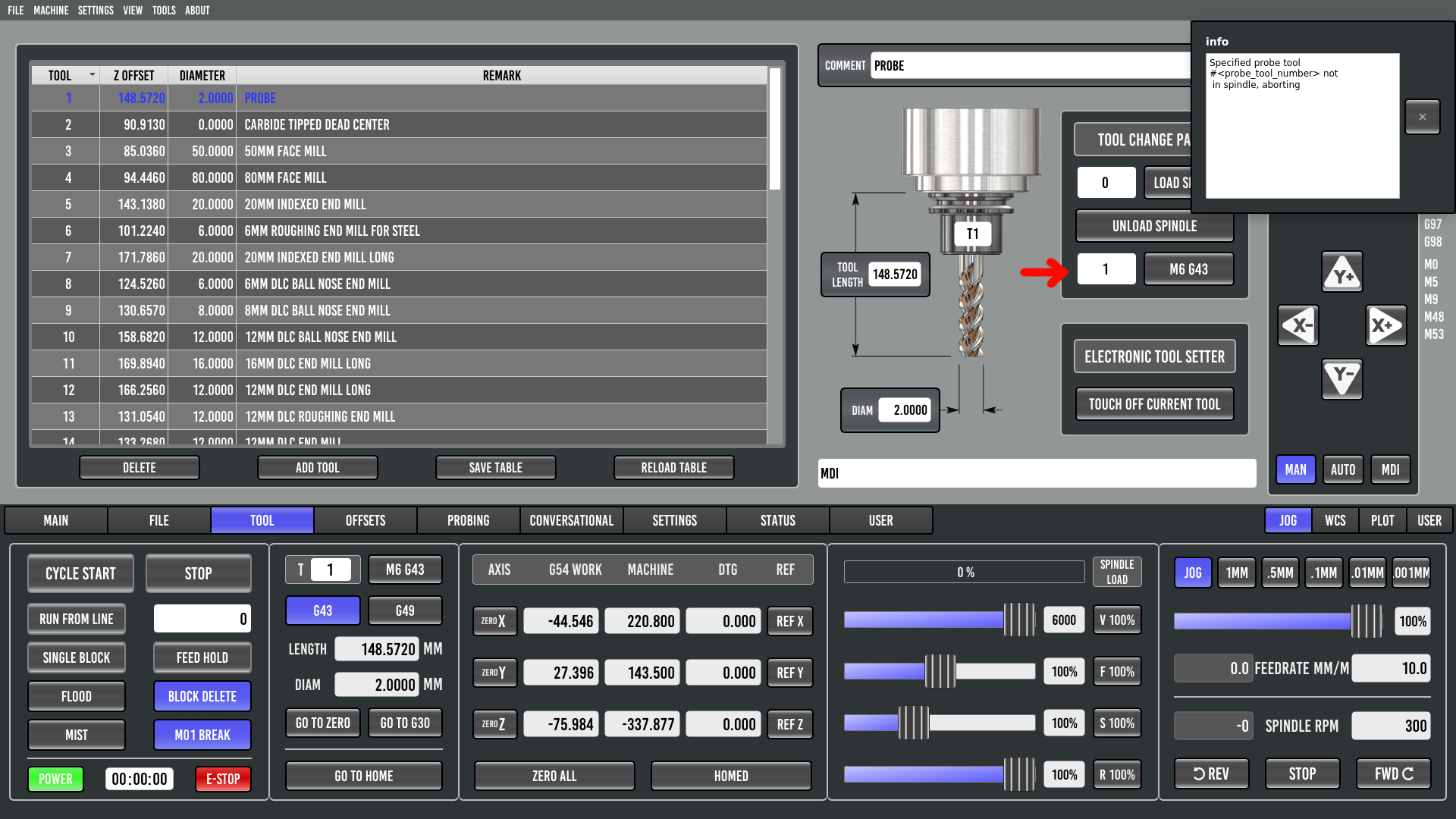

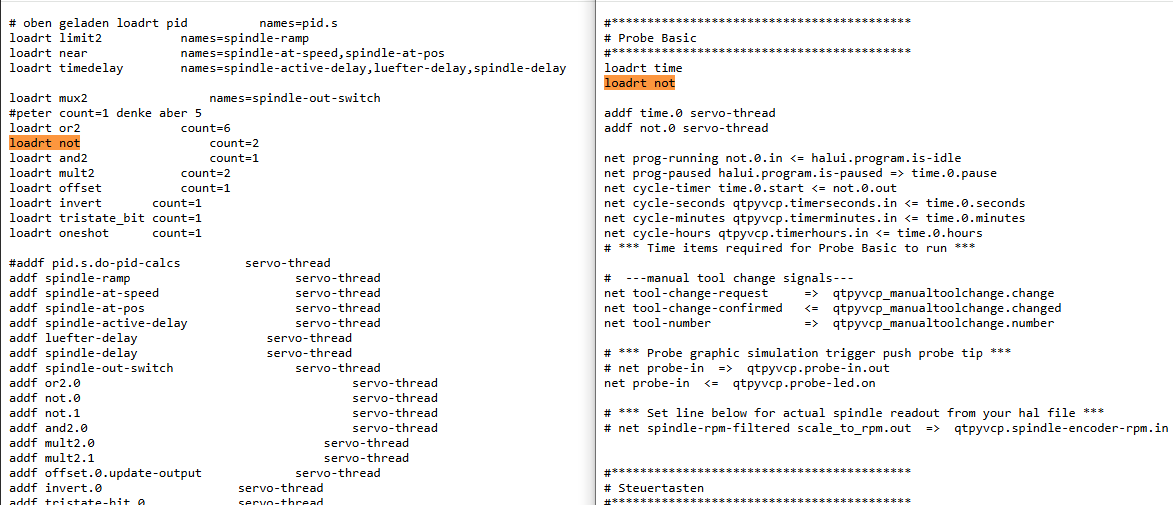

Specified probe tool not in spindle error after upgrade was created by Unlogic

Specified probe tool not in spindle error after upgrade

Category: QtPyVCP

- Lcvette

17 Dec 2024 13:05

- Lcvette

17 Dec 2024 12:58 - 17 Dec 2024 12:59

- Cant do this anymore bye all

17 Dec 2024 12:52

Replied by Cant do this anymore bye all on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- meister

- meister

17 Dec 2024 12:52

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- Cant do this anymore bye all

17 Dec 2024 12:40 - 19 Dec 2024 22:22

Replied by Cant do this anymore bye all on topic Raspberry Pi 5 with 7c81 WORKING!

Raspberry Pi 5 with 7c81 WORKING!

Category: Driver Boards

- epineh

- epineh

17 Dec 2024 12:22

Replied by epineh on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- agima2

- agima2

17 Dec 2024 12:15

Replied by agima2 on topic Linux CNC auf Virtualbox Simulation

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- WKS-3D

17 Dec 2024 11:16

Replied by WKS-3D on topic Poti nur wirksam bei mm/min (Drehmaschine)

Poti nur wirksam bei mm/min (Drehmaschine)

Category: Deutsch

- WKS-3D

17 Dec 2024 11:13

Replied by WKS-3D on topic Poti nur wirksam bei mm/min (Drehmaschine)

Poti nur wirksam bei mm/min (Drehmaschine)

Category: Deutsch

- meister

- meister

17 Dec 2024 10:34

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- MaHa

- MaHa

17 Dec 2024 10:27

Replied by MaHa on topic Poti nur wirksam bei mm/min (Drehmaschine)

Poti nur wirksam bei mm/min (Drehmaschine)

Category: Deutsch

- Zayoo

- Zayoo

17 Dec 2024 10:03 - 17 Dec 2024 10:28

- onceloved

17 Dec 2024 08:46

Replied by onceloved on topic Home position using ethercat servo position (absolute encoder value).

Home position using ethercat servo position (absolute encoder value).

Category: General LinuxCNC Questions

Time to create page: 0.606 seconds