Search Results (Searched for: )

- royka

- royka

17 Oct 2024 19:52

Replied by royka on topic Can the OPI5 be Configured to Run LCNC?

Can the OPI5 be Configured to Run LCNC?

Category: Computers and Hardware

- robh

- robh

17 Oct 2024 19:45

Replied by robh on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

- Tchefter

17 Oct 2024 19:38

Replied by Tchefter on topic Welche Tasten haben die Achsen?

Welche Tasten haben die Achsen?

Category: Deutsch

- PCW

17 Oct 2024 19:05

Replied by PCW on topic Machine moves when you stop program in the middle

Machine moves when you stop program in the middle

Category: General LinuxCNC Questions

- Nixus

- Nixus

17 Oct 2024 19:05 - 17 Oct 2024 19:06

Help with Denford Machine AXIS config was created by Nixus

Help with Denford Machine AXIS config

Category: General LinuxCNC Questions

- Muecke

17 Oct 2024 18:59

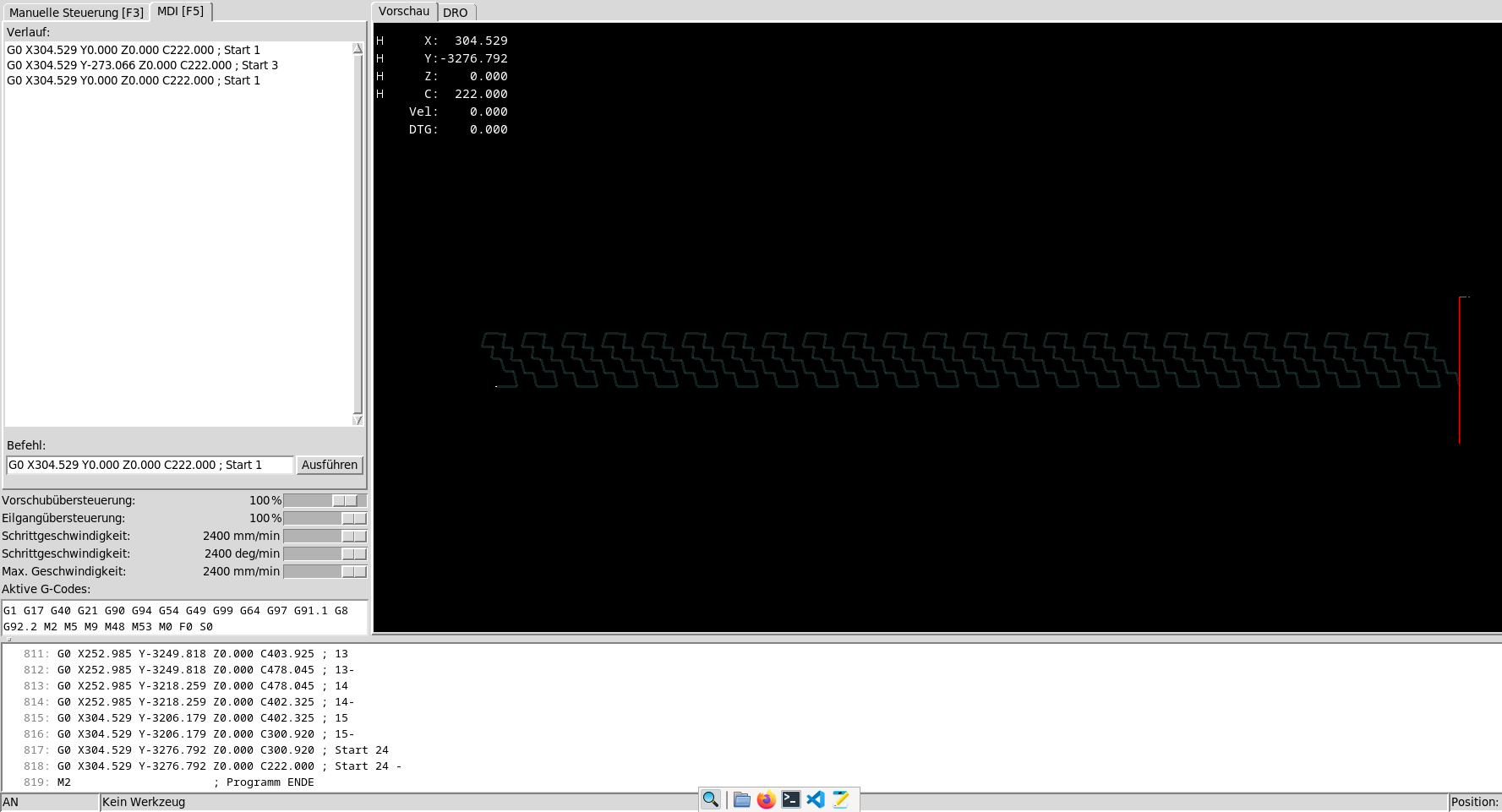

Replied by Muecke on topic Unterstützung bei der Automatisierung einer Simulation

Unterstützung bei der Automatisierung einer Simulation

Category: Deutsch

- gardenweazel

17 Oct 2024 18:05

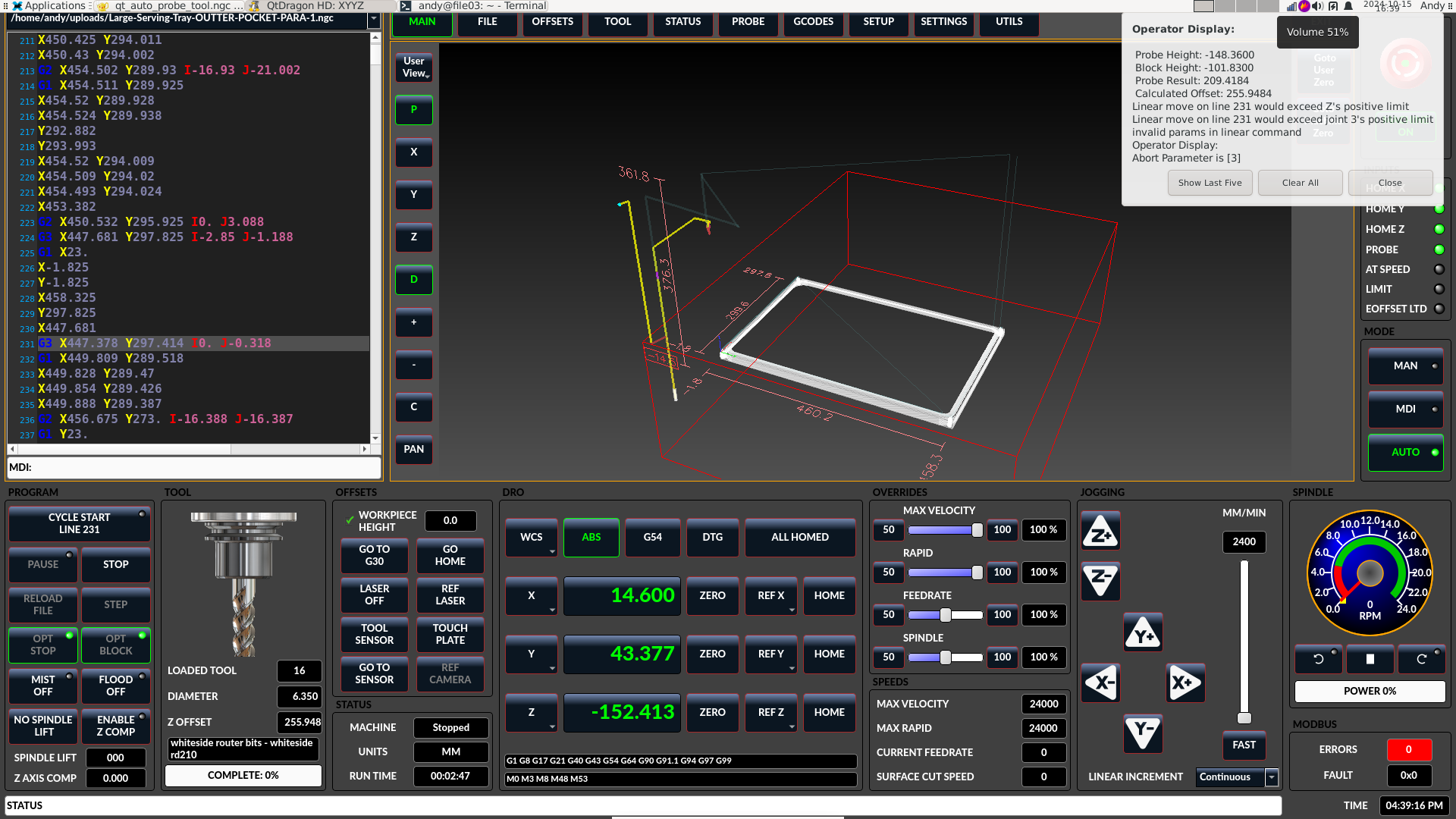

Inconsistent values from Versaprobe was created by gardenweazel

Inconsistent values from Versaprobe

Category: Qtvcp

- btvpimill

- btvpimill

17 Oct 2024 18:02

Machine moves when you stop program in the middle was created by btvpimill

Machine moves when you stop program in the middle

Category: General LinuxCNC Questions

- PCW

17 Oct 2024 17:48

Replied by PCW on topic Getting started with 6i25+7i75+7i85s

Getting started with 6i25+7i75+7i85s

Category: PnCConf Wizard

Time to create page: 0.422 seconds