Search Results (Searched for: )

- besriworld

- besriworld

14 Aug 2024 15:52

Replied by besriworld on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- Todd Zuercher

14 Aug 2024 15:41

Replied by Todd Zuercher on topic Configuring a dual stage axis

Configuring a dual stage axis

Category: Advanced Configuration

- PCW

14 Aug 2024 15:24

Replied by PCW on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- mighty_mick

14 Aug 2024 14:59

Replied by mighty_mick on topic How can I modify trivkins.c? (and also other kinematics files)

How can I modify trivkins.c? (and also other kinematics files)

Category: General LinuxCNC Questions

- Todd Zuercher

14 Aug 2024 14:12

Replied by Todd Zuercher on topic LED to indicate M3/M5 status

LED to indicate M3/M5 status

Category: GladeVCP

- tommylight

14 Aug 2024 13:45

Replied by tommylight on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- arijitdutta

- arijitdutta

14 Aug 2024 13:38

Replied by arijitdutta on topic PnCConf USB Jogging Problem

PnCConf USB Jogging Problem

Category: PnCConf Wizard

- Todd Zuercher

14 Aug 2024 13:32

Replied by Todd Zuercher on topic LED to indicate M3/M5 status

LED to indicate M3/M5 status

Category: GladeVCP

- JT

14 Aug 2024 12:59

- besriworld

- besriworld

14 Aug 2024 12:34 - 14 Aug 2024 12:35

Replied by besriworld on topic OLD Lathe conversion to a CNC

OLD Lathe conversion to a CNC

Category: Turning

- Aciera

14 Aug 2024 12:01

Replied by Aciera on topic How can I modify trivkins.c? (and also other kinematics files)

How can I modify trivkins.c? (and also other kinematics files)

Category: General LinuxCNC Questions

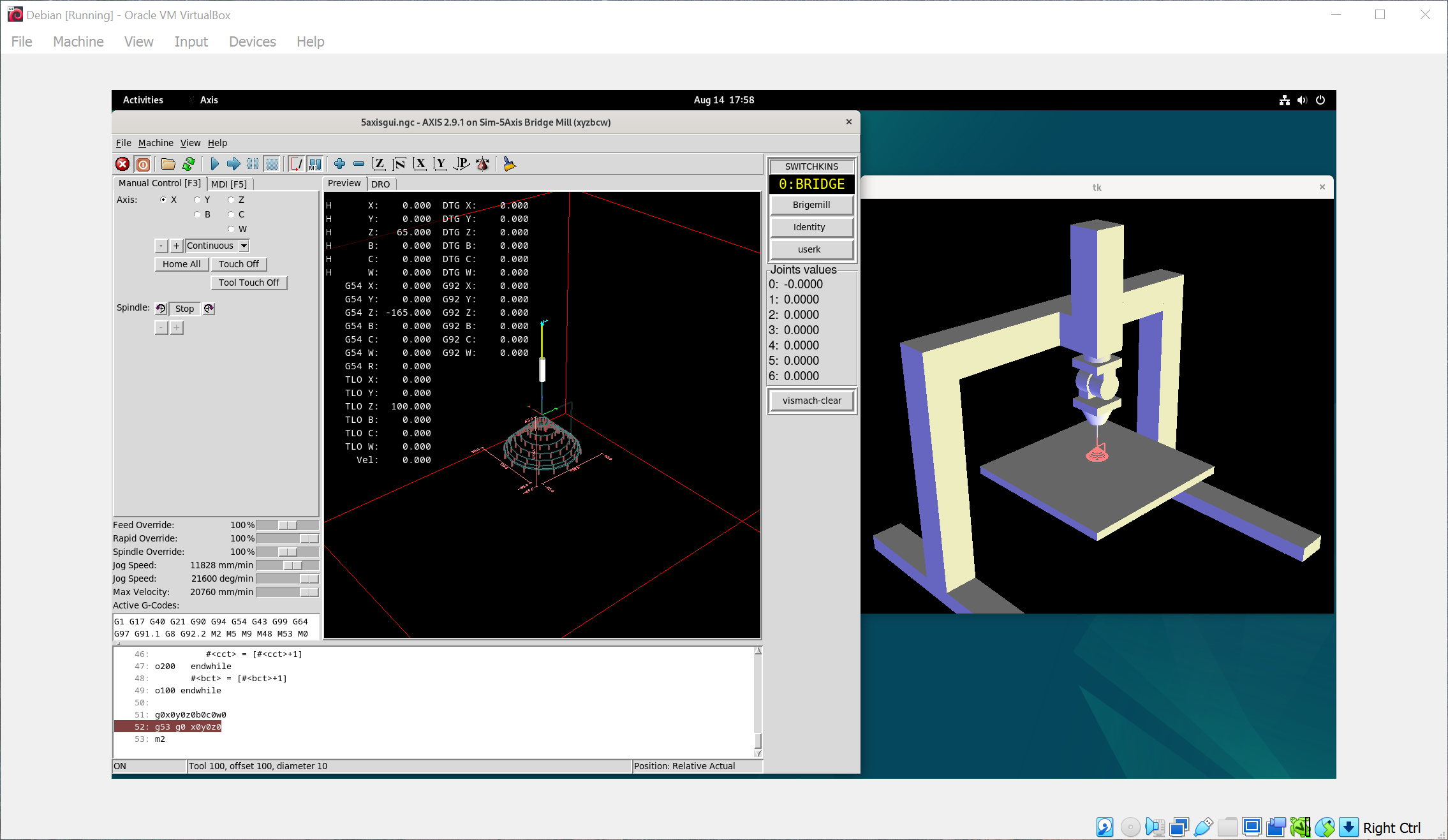

- Aciera

14 Aug 2024 11:27 - 14 Aug 2024 12:17

Replied by Aciera on topic How to add user kinematics for 5 axis bridge mill?

How to add user kinematics for 5 axis bridge mill?

Category: General LinuxCNC Questions

- winyk

- winyk

14 Aug 2024 11:01

How to add user kinematics for 5 axis bridge mill? was created by winyk

How to add user kinematics for 5 axis bridge mill?

Category: General LinuxCNC Questions

- nmsk

14 Aug 2024 10:06 - 15 Aug 2024 11:24

Can't set it to OP when configPdos is true was created by nmsk

Can't set it to OP when configPdos is true

Category: EtherCAT

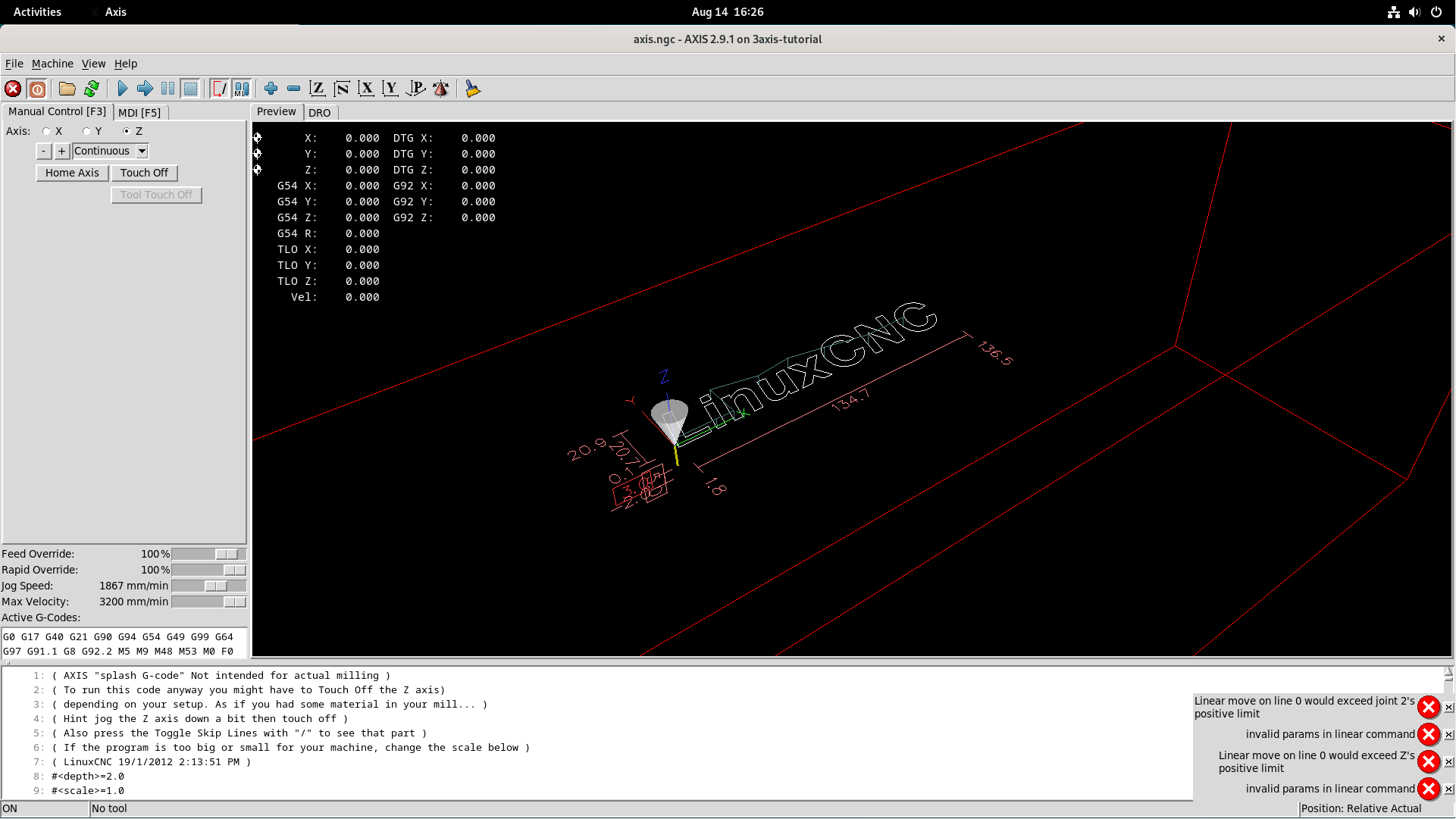

- winyk

- winyk

14 Aug 2024 10:03

Replied by winyk on topic How can I modify trivkins.c? (and also other kinematics files)

How can I modify trivkins.c? (and also other kinematics files)

Category: General LinuxCNC Questions

Time to create page: 0.504 seconds