Search Results (Searched for: )

- NWE

21 Feb 2026 15:25

Replied by NWE on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- Dudelbert

- Dudelbert

21 Feb 2026 15:24

Replied by Dudelbert on topic Considering a Full Rewire on a Working Schaublin 125 CNC

Considering a Full Rewire on a Working Schaublin 125 CNC

Category: Turning

- Marco61

- Marco61

21 Feb 2026 15:23

Replied by Marco61 on topic Buttons in cutom panel look conected but did not work

Buttons in cutom panel look conected but did not work

Category: pyVCP

- michaeln

- michaeln

21 Feb 2026 15:13

Replied by michaeln on topic G-code wizard für Gmoccapy

G-code wizard für Gmoccapy

Category: Gmoccapy

- michaeln

- michaeln

21 Feb 2026 15:07

Replied by michaeln on topic NativeCam on LinuxCNC 2.9.3

NativeCam on LinuxCNC 2.9.3

Category: NativeCAM

- tommylight

21 Feb 2026 14:24

Replied by tommylight on topic Buttons in cutom panel look conected but did not work

Buttons in cutom panel look conected but did not work

Category: pyVCP

- masawee

- masawee

21 Feb 2026 13:04

Replied by masawee on topic Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Linuxcnc 2.9.2 and 2.93 images for Raspberry Pi 4b & 5

Category: Installing LinuxCNC

- Christian

- Christian

21 Feb 2026 12:20

Replied by Christian on topic Mesa 7i76EU - how to enable mode 2?

Mesa 7i76EU - how to enable mode 2?

Category: Computers and Hardware

- DerKlotz

- DerKlotz

21 Feb 2026 12:09 - 21 Feb 2026 12:51

Replied by DerKlotz on topic Add Buttons in Probe Basic

Add Buttons in Probe Basic

Category: QtPyVCP

- Marco61

- Marco61

21 Feb 2026 10:10

Buttons in cutom panel look conected but did not work was created by Marco61

Buttons in cutom panel look conected but did not work

Category: pyVCP

- tcbmetalworks

- tcbmetalworks

21 Feb 2026 09:03

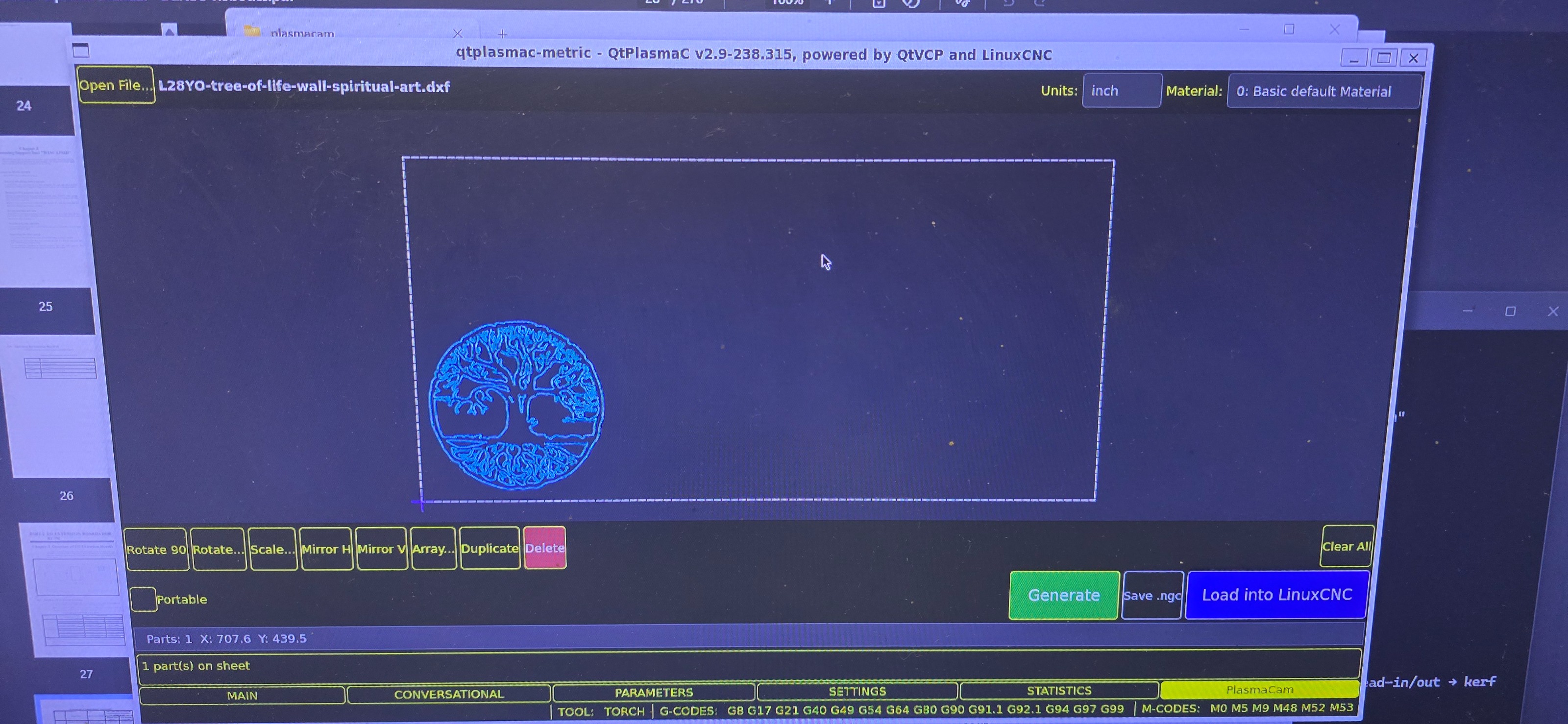

Replied by tcbmetalworks on topic QTPLASMAC integrated cad/cam

QTPLASMAC integrated cad/cam

Category: Plasmac

- tcbmetalworks

- tcbmetalworks

21 Feb 2026 08:30

Replied by tcbmetalworks on topic QTPLASMAC integrated cad/cam

QTPLASMAC integrated cad/cam

Category: Plasmac

- Hakan

- Hakan

21 Feb 2026 07:49

Replied by Hakan on topic QTPLASMAC integrated cad/cam

QTPLASMAC integrated cad/cam

Category: Plasmac

- tcbmetalworks

- tcbmetalworks

21 Feb 2026 07:37

Replied by tcbmetalworks on topic QTPLASMAC integrated cad/cam

QTPLASMAC integrated cad/cam

Category: Plasmac

- tcbmetalworks

- tcbmetalworks

21 Feb 2026 07:18

Replied by tcbmetalworks on topic QTPLASMAC integrated cad/cam

QTPLASMAC integrated cad/cam

Category: Plasmac

Time to create page: 0.838 seconds