Search Results (Searched for: )

- andypugh

22 Nov 2025 22:25

Replied by andypugh on topic How do you vote in the hardware survey?

How do you vote in the hardware survey?

Category: General LinuxCNC Questions

- Muzzer

- Muzzer

22 Nov 2025 22:01

Replied by Muzzer on topic Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Category: Gmoccapy

- mooser

- mooser

22 Nov 2025 21:58

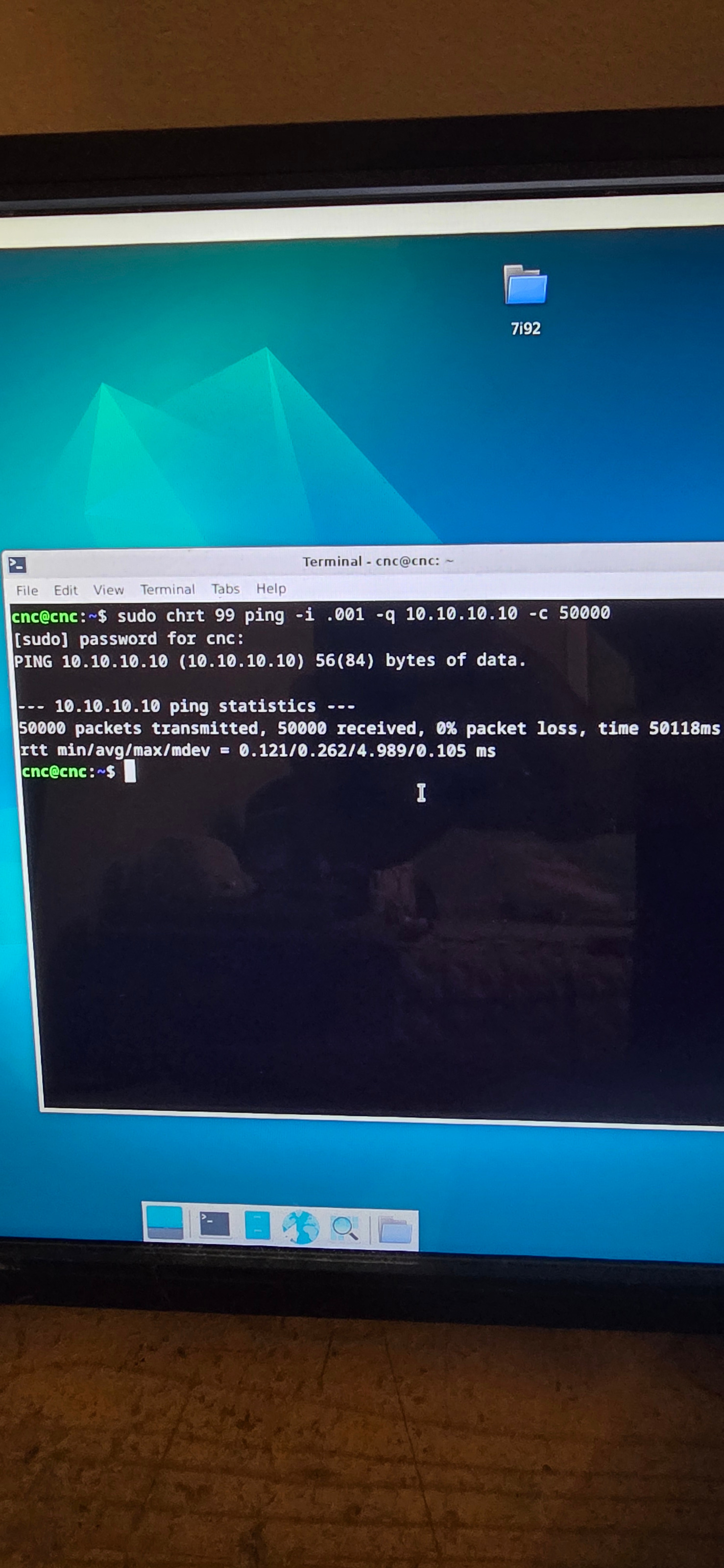

latency (netowork?) 7010 with 7i96s+7i84u was created by mooser

latency (netowork?) 7010 with 7i96s+7i84u

Category: Computers and Hardware

- unknown

- unknown

22 Nov 2025 21:55

Replied by unknown on topic linuxcnc_2.9.4-amd64.hybrid.iso cheksum?

linuxcnc_2.9.4-amd64.hybrid.iso cheksum?

Category: General LinuxCNC Questions

- bszoke

- bszoke

22 Nov 2025 21:41

- TripleM

- TripleM

22 Nov 2025 21:26 - 22 Nov 2025 21:28

Gewindeschneiden G33.1 k-word missing. was created by TripleM

Gewindeschneiden G33.1 k-word missing.

Category: Deutsch

- BoMadsen

- BoMadsen

22 Nov 2025 20:27

Replied by BoMadsen on topic 7i76eu steppers don't move

7i76eu steppers don't move

Category: Driver Boards

- Sekai

- Sekai

22 Nov 2025 19:08

Replied by Sekai on topic Chinese Mesa 7I92 from aliexpress NEW

Chinese Mesa 7I92 from aliexpress NEW

Category: Driver Boards

- abs32

- abs32

22 Nov 2025 18:37 - 22 Nov 2025 18:42

Replied by abs32 on topic Probe tripped during non-probe move deadlock

Probe tripped during non-probe move deadlock

Category: General LinuxCNC Questions

- 1911ut

- 1911ut

22 Nov 2025 18:37

Replied by 1911ut on topic Is something up with 2.9.7 (joint errors)

Is something up with 2.9.7 (joint errors)

Category: General LinuxCNC Questions

- PCW

22 Nov 2025 18:35 - 22 Nov 2025 18:49

Replied by PCW on topic 7i76eu steppers don't move

7i76eu steppers don't move

Category: Driver Boards

- Lcvette

22 Nov 2025 18:31

Replied by Lcvette on topic probe_basic_postgui.hal conflicts with my gamepad*.hal

probe_basic_postgui.hal conflicts with my gamepad*.hal

Category: QtPyVCP

- BoMadsen

- BoMadsen

22 Nov 2025 18:25

Replied by BoMadsen on topic 7i76eu steppers don't move

7i76eu steppers don't move

Category: Driver Boards

- juergen-home

- juergen-home

22 Nov 2025 18:19

Replied by juergen-home on topic probe_basic_postgui.hal conflicts with my gamepad*.hal

probe_basic_postgui.hal conflicts with my gamepad*.hal

Category: QtPyVCP

- Lcvette

22 Nov 2025 18:05

Replied by Lcvette on topic probe_basic_postgui.hal conflicts with my gamepad*.hal

probe_basic_postgui.hal conflicts with my gamepad*.hal

Category: QtPyVCP

Time to create page: 0.212 seconds