Search Results (Searched for: )

- MaHa

- MaHa

22 Feb 2025 15:41

Replied by MaHa on topic global named parameter error

global named parameter error

Category: General LinuxCNC Questions

- jyeomans

- jyeomans

22 Feb 2025 15:24

- Grotius

22 Feb 2025 15:02

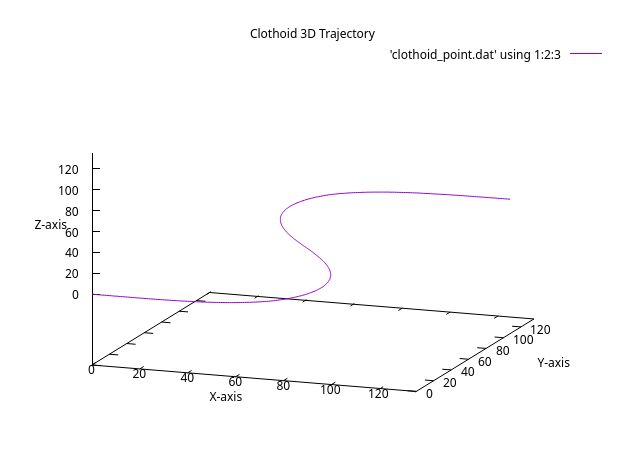

Replied by Grotius on topic scurve trajectory planner

scurve trajectory planner

Category: General LinuxCNC Questions

- WKS-3D

22 Feb 2025 13:11 - 22 Feb 2025 13:14

Abfrage Werkzeugrevolver verschlossen was created by WKS-3D

Abfrage Werkzeugrevolver verschlossen

Category: Deutsch

- JT

22 Feb 2025 12:47

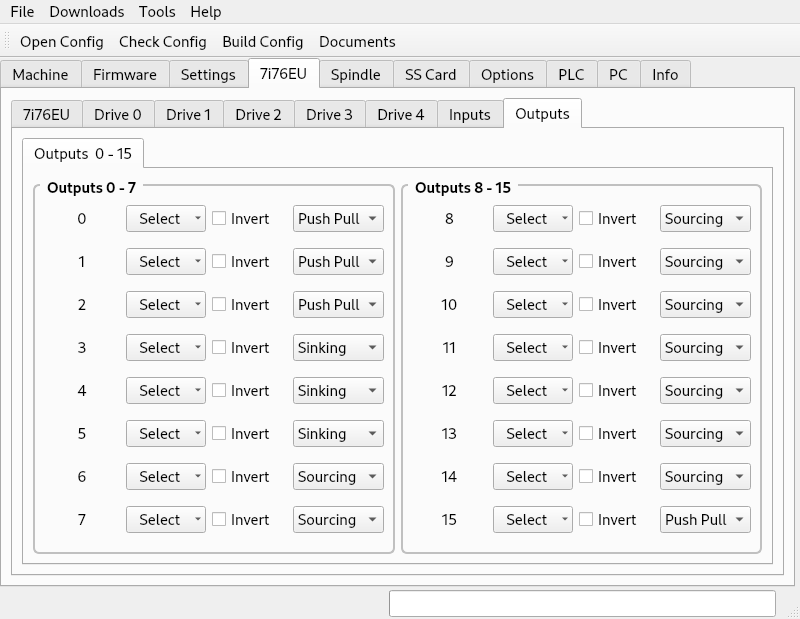

Replied by JT on topic Mesa Configuration Tool

Mesa Configuration Tool

Category: Configuration Tools

- JuFu

- JuFu

22 Feb 2025 12:11

- Hakan

- Hakan

22 Feb 2025 12:05 - 22 Feb 2025 12:11

Replied by Hakan on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- Yaroslav

- Yaroslav

22 Feb 2025 11:55

- MaxEkb77

22 Feb 2025 11:31

global named parameter error was created by MaxEkb77

global named parameter error

Category: General LinuxCNC Questions

- Nserega.90

- Nserega.90

22 Feb 2025 10:35 - 22 Feb 2025 11:10

- RDA

- RDA

22 Feb 2025 10:32

Replied by RDA on topic EtherCAT plasma torch voltage reader

EtherCAT plasma torch voltage reader

Category: Show Your Stuff

- jjdege

22 Feb 2025 10:28 - 22 Feb 2025 16:51

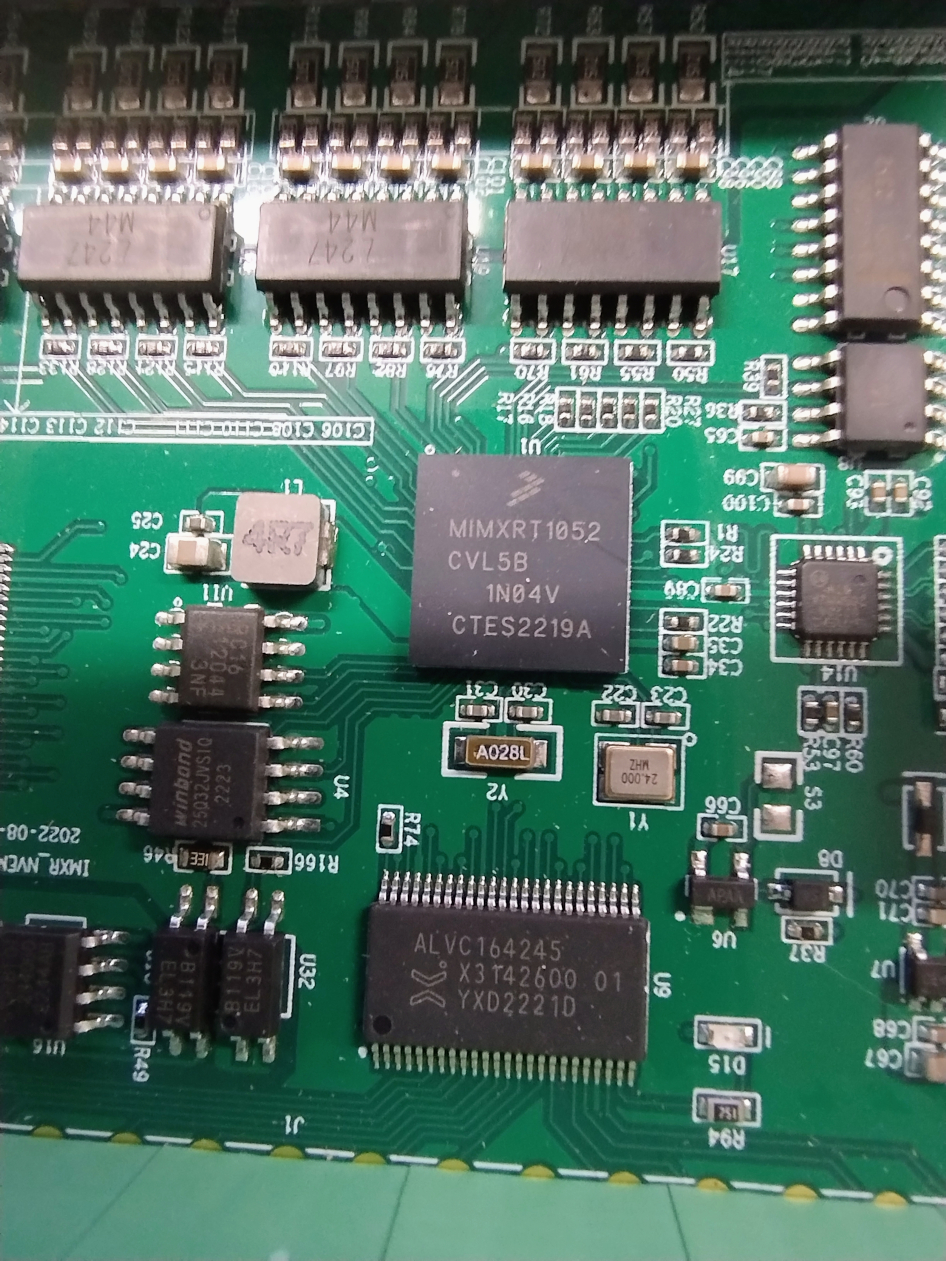

Replied by jjdege on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- timo

- timo

22 Feb 2025 09:40

How to integrate manual spindle lock into Axis GUI? was created by timo

How to integrate manual spindle lock into Axis GUI?

Category: General LinuxCNC Questions

- unknown

- unknown

22 Feb 2025 09:33

Replied by unknown on topic Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Linuxcnc & the Raspberry Pi (4 & 5) Official Images Only!!!

Category: Installing LinuxCNC

- cmorley

- cmorley

22 Feb 2025 09:15

Replied by cmorley on topic development of a qt version of ncam

development of a qt version of ncam

Category: Qtvcp

Time to create page: 1.082 seconds