Search Results (Searched for: )

- Cant do this anymore bye all

16 Jan 2025 13:10

Replied by Cant do this anymore bye all on topic Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Category: Installing LinuxCNC

- spumco

- spumco

16 Jan 2025 13:09

Replied by spumco on topic Help Needed: Z-Axis Linear Guide Vibrations at Specific Speeds

Help Needed: Z-Axis Linear Guide Vibrations at Specific Speeds

Category: General LinuxCNC Questions

- gene_weber

16 Jan 2025 12:38

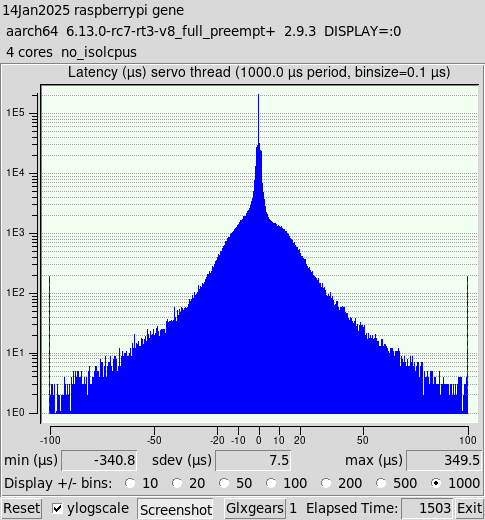

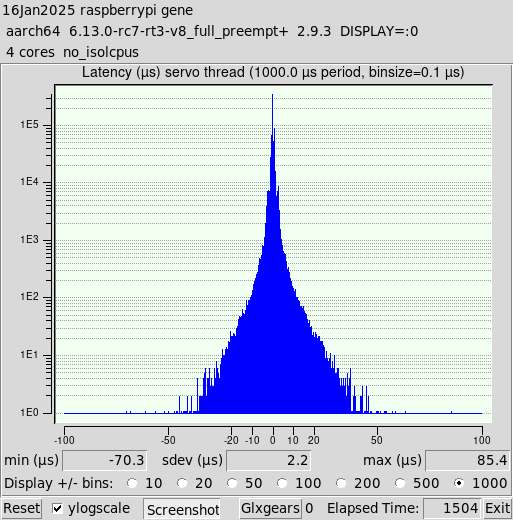

Replied by gene_weber on topic Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Raspberry Pi OS PREEMPT RT 6.13 Kernel Cookbook

Category: Installing LinuxCNC

- timo

- timo

16 Jan 2025 12:26 - 16 Jan 2025 12:30

Replied by timo on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- hellvetica

- hellvetica

16 Jan 2025 12:18

Replied by hellvetica on topic Using G64 with M66 for smooth robot control

Using G64 with M66 for smooth robot control

Category: General LinuxCNC Questions

- snowgoer540

16 Jan 2025 12:18 - 16 Jan 2025 12:22

Replied by snowgoer540 on topic QtPlasmaC v2.9 - Time between turning off and back on the arc on a Powermax 105

QtPlasmaC v2.9 - Time between turning off and back on the arc on a Powermax 105

Category: Plasma & Laser

- programador

16 Jan 2025 12:11

- Sternfox

- Sternfox

16 Jan 2025 12:06

- programador

16 Jan 2025 11:59

- spumco

- spumco

16 Jan 2025 11:42

Replied by spumco on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- rodw

16 Jan 2025 11:10

Replied by rodw on topic 7i96s Arc Voltage + Encoder Fault

7i96s Arc Voltage + Encoder Fault

Category: Plasma & Laser

- timo

- timo

16 Jan 2025 11:04 - 16 Jan 2025 11:09

- KrisR

- KrisR

16 Jan 2025 10:22

- Gautham

- Gautham

16 Jan 2025 09:39

Replied by Gautham on topic Rotating Axis Controlled by a Ballscrew

Rotating Axis Controlled by a Ballscrew

Category: Basic Configuration

- hellvetica

- hellvetica

16 Jan 2025 09:38

Replied by hellvetica on topic Using G64 with M66 for smooth robot control

Using G64 with M66 for smooth robot control

Category: General LinuxCNC Questions

Time to create page: 0.530 seconds