Search Results (Searched for: )

- PCW

08 Jan 2025 16:40

Replied by PCW on topic 7i96s Arc Voltage + Encoder Fault

7i96s Arc Voltage + Encoder Fault

Category: Plasma & Laser

- iastate_tka

- iastate_tka

08 Jan 2025 16:31

Omron/Generic Ethercat Driver - Communications Synch Error was created by iastate_tka

Omron/Generic Ethercat Driver - Communications Synch Error

Category: EtherCAT

- sharp_reaper

- sharp_reaper

08 Jan 2025 16:19 - 08 Jan 2025 16:29

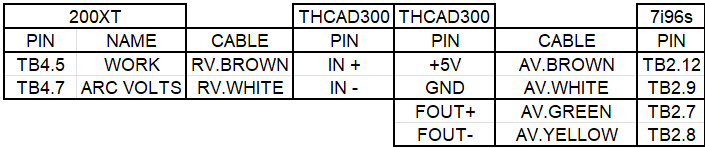

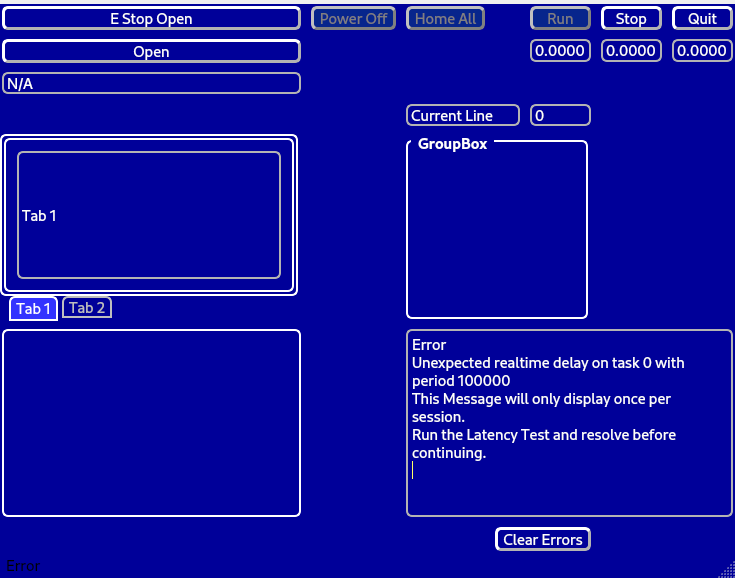

Replied by sharp_reaper on topic 7i96s Arc Voltage + Encoder Fault

7i96s Arc Voltage + Encoder Fault

Category: Plasma & Laser

- PCW

08 Jan 2025 16:06

- PCW

08 Jan 2025 15:58

Replied by PCW on topic 7i96s Arc Voltage + Encoder Fault

7i96s Arc Voltage + Encoder Fault

Category: Plasma & Laser

- sharp_reaper

- sharp_reaper

08 Jan 2025 15:34 - 08 Jan 2025 15:42

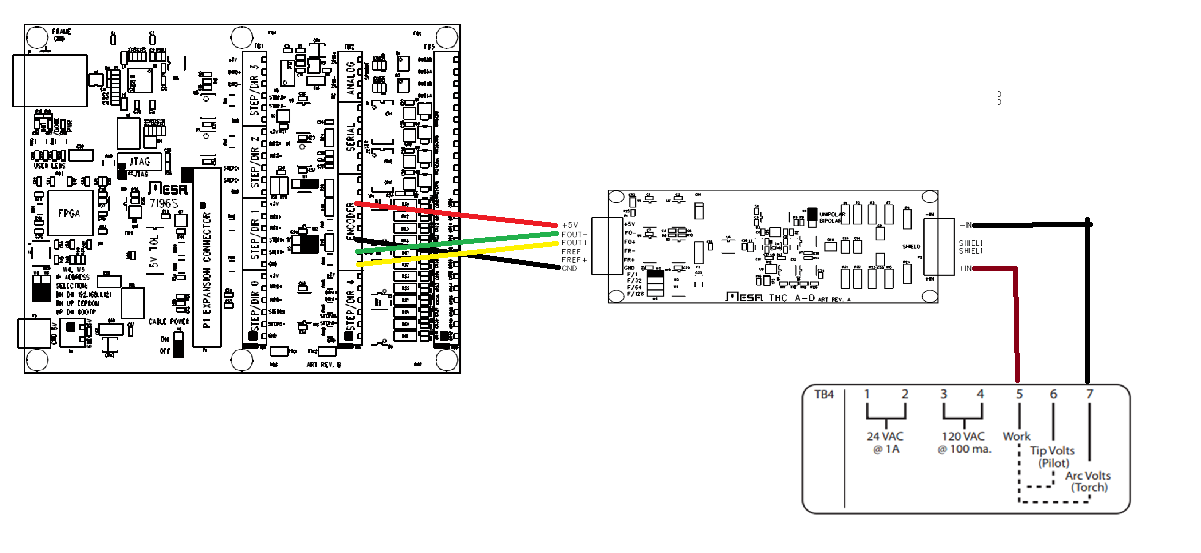

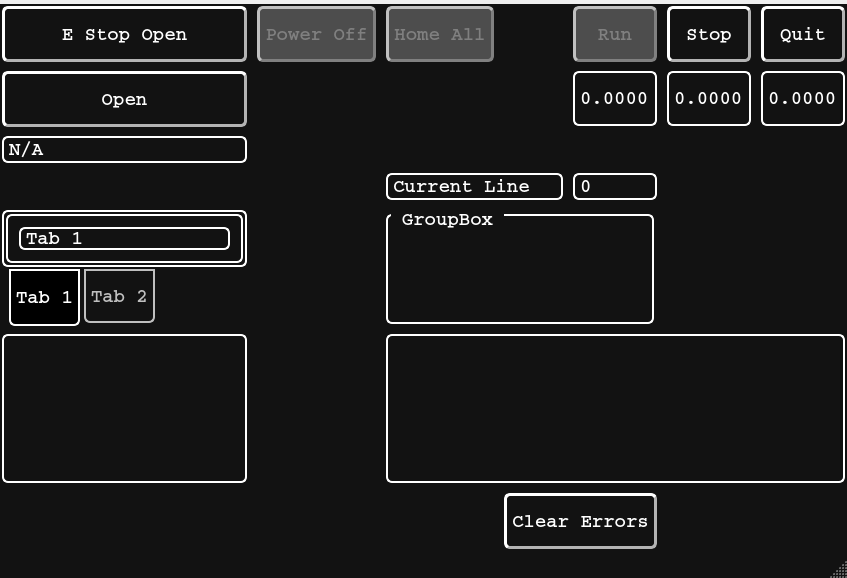

7i96s Arc Voltage + Encoder Fault was created by sharp_reaper

7i96s Arc Voltage + Encoder Fault

Category: Plasma & Laser

- JT

08 Jan 2025 15:18 - 08 Jan 2025 15:20

- Yaroslav

- Yaroslav

08 Jan 2025 15:07

M6 Remap Lathe (Remap T & ignore M6) was created by Yaroslav

M6 Remap Lathe (Remap T & ignore M6)

Category: General LinuxCNC Questions

- JimS

- JimS

08 Jan 2025 15:04

Replied by JimS on topic Strange error after stopping file and adjusting part zero

Strange error after stopping file and adjusting part zero

Category: General LinuxCNC Questions

- tommylight

08 Jan 2025 15:03

- JimS

- JimS

08 Jan 2025 14:59

Replied by JimS on topic Strange error after stopping file and adjusting part zero

Strange error after stopping file and adjusting part zero

Category: General LinuxCNC Questions

- MacKaye

- MacKaye

08 Jan 2025 14:50

Replied by MacKaye on topic Weiler DZ26 Millturn Conversion

Weiler DZ26 Millturn Conversion

Category: Turning

- Aciera

08 Jan 2025 14:39

- Aciera

08 Jan 2025 14:35 - 08 Jan 2025 14:36

- Moutomation

- Moutomation

08 Jan 2025 14:24 - 08 Jan 2025 14:29

Time to create page: 0.503 seconds