Search Results (Searched for: )

- Aciera

01 Dec 2024 18:50

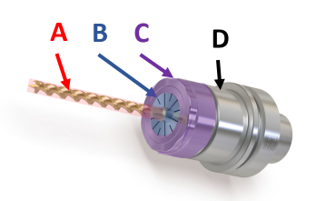

Replied by Aciera on topic [OT] Frage zu Spannzangen und Eigenbau-Werkzeug

[OT] Frage zu Spannzangen und Eigenbau-Werkzeug

Category: Deutsch

- RDA

- RDA

01 Dec 2024 18:10

- royka

- royka

01 Dec 2024 18:09 - 01 Dec 2024 23:06

Replied by royka on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

- Muecke

01 Dec 2024 18:03

Replied by Muecke on topic [OT] Frage zu Spannzangen und Eigenbau-Werkzeug

[OT] Frage zu Spannzangen und Eigenbau-Werkzeug

Category: Deutsch

- RDA

- RDA

01 Dec 2024 18:02

- Kasper-001

01 Dec 2024 18:01

- Lcvette

01 Dec 2024 17:00

Replied by Lcvette on topic probe_basic_lathe vtk_backplot.py error

probe_basic_lathe vtk_backplot.py error

Category: QtPyVCP

- Lcvette

01 Dec 2024 16:55

- PCW

01 Dec 2024 16:25

Replied by PCW on topic Frage wegen Spindelencoder an 7i76

Frage wegen Spindelencoder an 7i76

Category: Deutsch

- Aciera

01 Dec 2024 16:16

Replied by Aciera on topic How to invoke an error message to be displayed in Axis?

How to invoke an error message to be displayed in Axis?

Category: General LinuxCNC Questions

- slowpoke

- slowpoke

01 Dec 2024 16:07

How to invoke an error message to be displayed in Axis? was created by slowpoke

How to invoke an error message to be displayed in Axis?

Category: General LinuxCNC Questions

- WKS-3D

01 Dec 2024 15:50

Replied by WKS-3D on topic Frage wegen Spindelencoder an 7i76

Frage wegen Spindelencoder an 7i76

Category: Deutsch

- kworm

- kworm

01 Dec 2024 15:47

Replied by kworm on topic Leadshine EL8 Servo Drives - EtherCAT

Leadshine EL8 Servo Drives - EtherCAT

Category: Advanced Configuration

- tommylight

01 Dec 2024 15:21

Washington Discovers the Metric System was created by tommylight

Washington Discovers the Metric System

Category: Off Topic and Test Posts

- PatJac

- PatJac

01 Dec 2024 15:17 - 01 Dec 2024 15:21

Replied by PatJac on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

Time to create page: 0.386 seconds