Search Results (Searched for: )

- Aciera

20 Jun 2024 14:44

Replied by Aciera on topic Can't get LinuxCNC to stop taking "shortcuts"

Can't get LinuxCNC to stop taking "shortcuts"

Category: General LinuxCNC Questions

- Aciera

20 Jun 2024 14:07

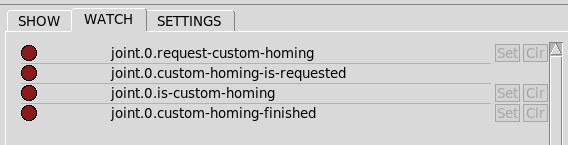

Replied by Aciera on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- eduard

20 Jun 2024 13:45

Replied by eduard on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- Aciera

20 Jun 2024 13:23

Replied by Aciera on topic Deckel FP4 Gearbox Comp

Deckel FP4 Gearbox Comp

Category: Advanced Configuration

- eduard

20 Jun 2024 13:12

Replied by eduard on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- Donb9261

20 Jun 2024 12:13

Replied by Donb9261 on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- Walkahz

- Walkahz

20 Jun 2024 12:02

Deckel FP4 Gearbox Comp was created by Walkahz

Deckel FP4 Gearbox Comp

Category: Advanced Configuration

- Donb9261

20 Jun 2024 11:53

Replied by Donb9261 on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- Cant do this anymore bye all

20 Jun 2024 11:08

Replied by Cant do this anymore bye all on topic Installing Linuxcnc in resberrypi

Installing Linuxcnc in resberrypi

Category: Installing LinuxCNC

- seyad

- seyad

20 Jun 2024 10:23

Replied by seyad on topic Installing Linuxcnc in resberrypi

Installing Linuxcnc in resberrypi

Category: Installing LinuxCNC

- tommylight

20 Jun 2024 10:20

Replied by tommylight on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- rodw

20 Jun 2024 09:12

Replied by rodw on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- cekaa

20 Jun 2024 09:01

Replied by cekaa on topic Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Help Needed: Cracking the Code on LinuxCNC Servo Homing Setup!

Category: EtherCAT

- jimwhiting

- jimwhiting

20 Jun 2024 08:25

Replied by jimwhiting on topic EtherCAT options for spindle encoder

EtherCAT options for spindle encoder

Category: EtherCAT

- pippin88

- pippin88

20 Jun 2024 07:34

Replied by pippin88 on topic EtherCAT options for spindle encoder

EtherCAT options for spindle encoder

Category: EtherCAT

Time to create page: 0.520 seconds