Search Results (Searched for: )

- Emanresu

- Emanresu

11 Jun 2024 19:29

Replied by Emanresu on topic Fusions CAM drives me crazy - Axis out of bounds

Fusions CAM drives me crazy - Axis out of bounds

Category: Fusion 360

- scda

11 Jun 2024 19:12

Replied by scda on topic Mesa 7i95T: Smartserial Port 2 for Mesa Modbus RS485

Mesa 7i95T: Smartserial Port 2 for Mesa Modbus RS485

Category: Driver Boards

- PCW

11 Jun 2024 18:58

- vally72

- vally72

11 Jun 2024 18:08

Confusion about steplen and dirhold was created by vally72

Confusion about steplen and dirhold

Category: General LinuxCNC Questions

- redeye_joe

11 Jun 2024 17:30

use a older snapon plasma50 for DIY CNC was created by redeye_joe

use a older snapon plasma50 for DIY CNC

Category: Plasmac

- Clive S

- Clive S

11 Jun 2024 16:36

- PCW

11 Jun 2024 16:35

- Clive S

- Clive S

11 Jun 2024 16:30

- PCW

11 Jun 2024 16:22

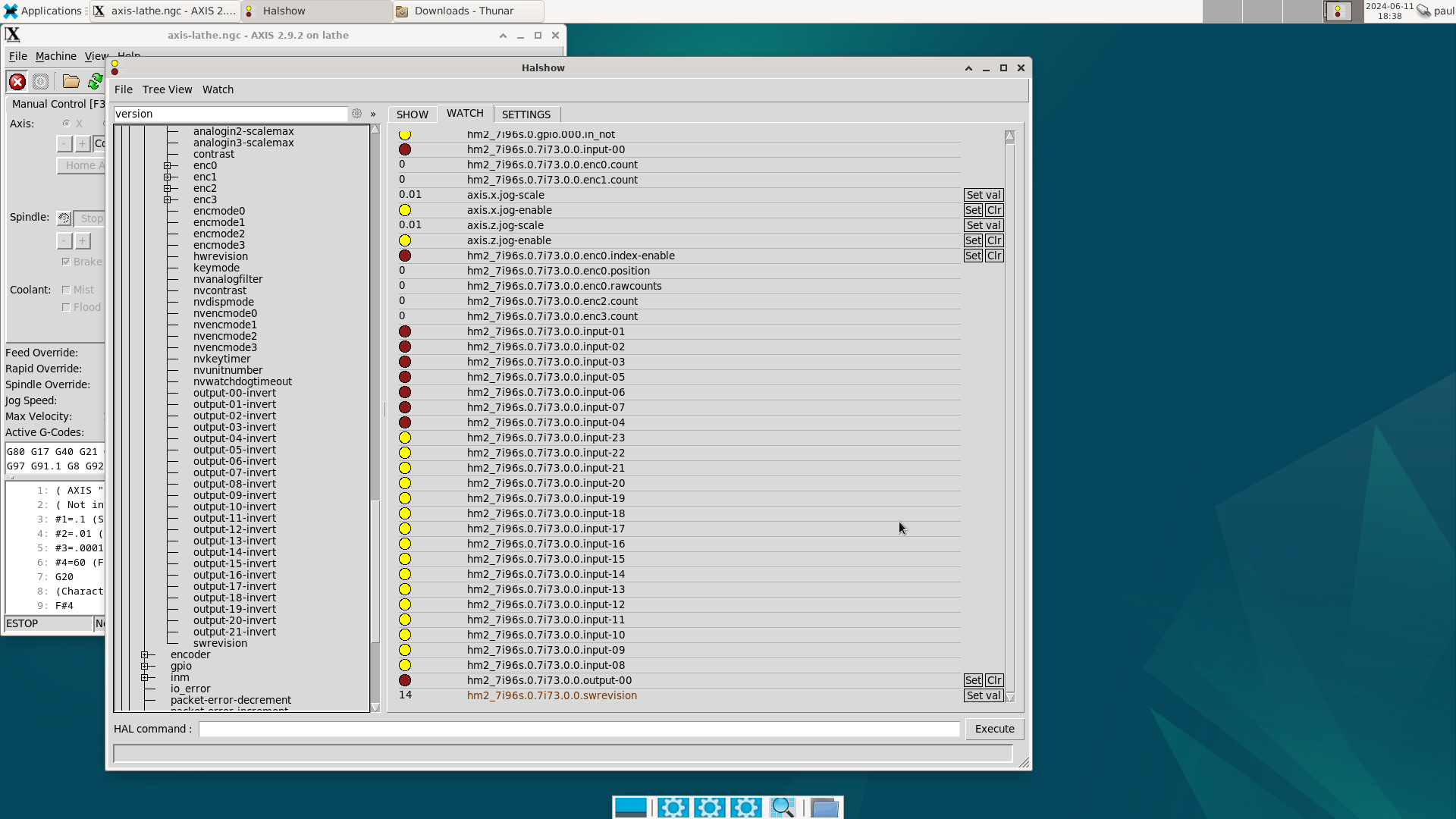

Replied by PCW on topic 7i73 seems to be correctly installed but not working

7i73 seems to be correctly installed but not working

Category: Driver Boards

- vibram

- vibram

11 Jun 2024 16:14

Replied by vibram on topic 7i73 seems to be correctly installed but not working

7i73 seems to be correctly installed but not working

Category: Driver Boards

- spumco

- spumco

11 Jun 2024 16:14

Replied by spumco on topic Z-axis homing - Y-axis tuning - ClearPath servo firmware updates

Z-axis homing - Y-axis tuning - ClearPath servo firmware updates

Category: General LinuxCNC Questions

- stonebite

- stonebite

11 Jun 2024 15:56

Replied by stonebite on topic PNCconf 7i92H and 7i76

PNCconf 7i92H and 7i76

Category: PnCConf Wizard

- PCW

11 Jun 2024 15:45

Replied by PCW on topic 7i73 seems to be correctly installed but not working

7i73 seems to be correctly installed but not working

Category: Driver Boards

- vibram

- vibram

11 Jun 2024 15:39

Replied by vibram on topic 7i73 seems to be correctly installed but not working

7i73 seems to be correctly installed but not working

Category: Driver Boards

- spumco

- spumco

11 Jun 2024 15:33

Replied by spumco on topic Schaublin 125-CNC retrofit.

Schaublin 125-CNC retrofit.

Category: Turning

Time to create page: 0.459 seconds