Search Results (Searched for: )

- Stran_ge

- Stran_ge

24 Oct 2024 21:08

Replied by Stran_ge on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- PCW

24 Oct 2024 20:56 - 24 Oct 2024 20:56

Replied by PCW on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- Stran_ge

- Stran_ge

24 Oct 2024 20:36

Replied by Stran_ge on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- cakeslob

- cakeslob

24 Oct 2024 20:34

Replied by cakeslob on topic Machine moves when you stop program in the middle

Machine moves when you stop program in the middle

Category: General LinuxCNC Questions

- PCW

24 Oct 2024 20:30

Replied by PCW on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- Stran_ge

- Stran_ge

24 Oct 2024 20:22 - 24 Oct 2024 20:28

Replied by Stran_ge on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- PCW

24 Oct 2024 20:14

Replied by PCW on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- tommylight

24 Oct 2024 20:10

Replied by tommylight on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- Stran_ge

- Stran_ge

24 Oct 2024 20:08

Replied by Stran_ge on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- PCW

24 Oct 2024 19:56

Replied by PCW on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- besriworld

- besriworld

24 Oct 2024 19:40 - 26 Oct 2024 21:46

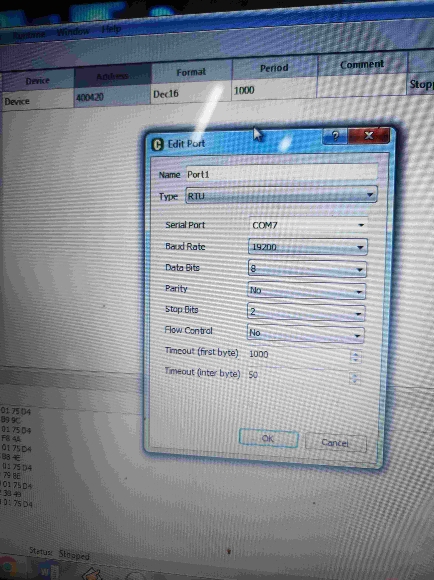

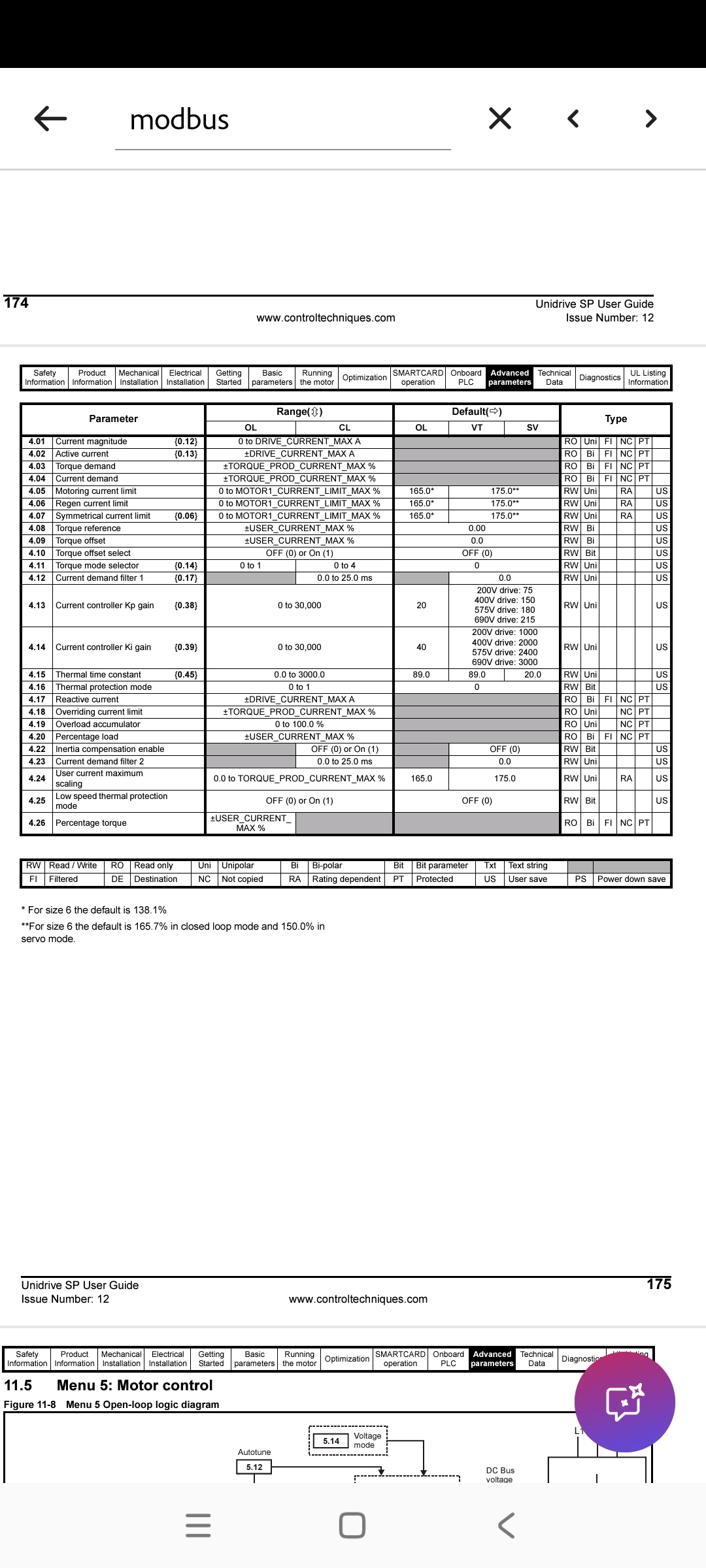

Replied by besriworld on topic Modbus Help - MB2HAL

Modbus Help - MB2HAL

Category: General LinuxCNC Questions

- RyanB

24 Oct 2024 19:31

Replied by RyanB on topic Could use some help with a tandem axis homing issue

Could use some help with a tandem axis homing issue

Category: Basic Configuration

- mylastpolo

- mylastpolo

24 Oct 2024 19:24

Replied by mylastpolo on topic Fanuc Servos Single Phase

Fanuc Servos Single Phase

Category: Computers and Hardware

- Stran_ge

- Stran_ge

24 Oct 2024 19:22

Replied by Stran_ge on topic Spindle servo step/dir Problems

Spindle servo step/dir Problems

Category: Advanced Configuration

- Grotius

24 Oct 2024 19:12

Replied by Grotius on topic linuxcnc trajectory planner

linuxcnc trajectory planner

Category: General LinuxCNC Questions

Time to create page: 1.557 seconds