Search Results (Searched for: )

- tommylight

22 Oct 2024 02:38

Replied by tommylight on topic Compiling linuxcnc with source code on Debian12 resulted in an error

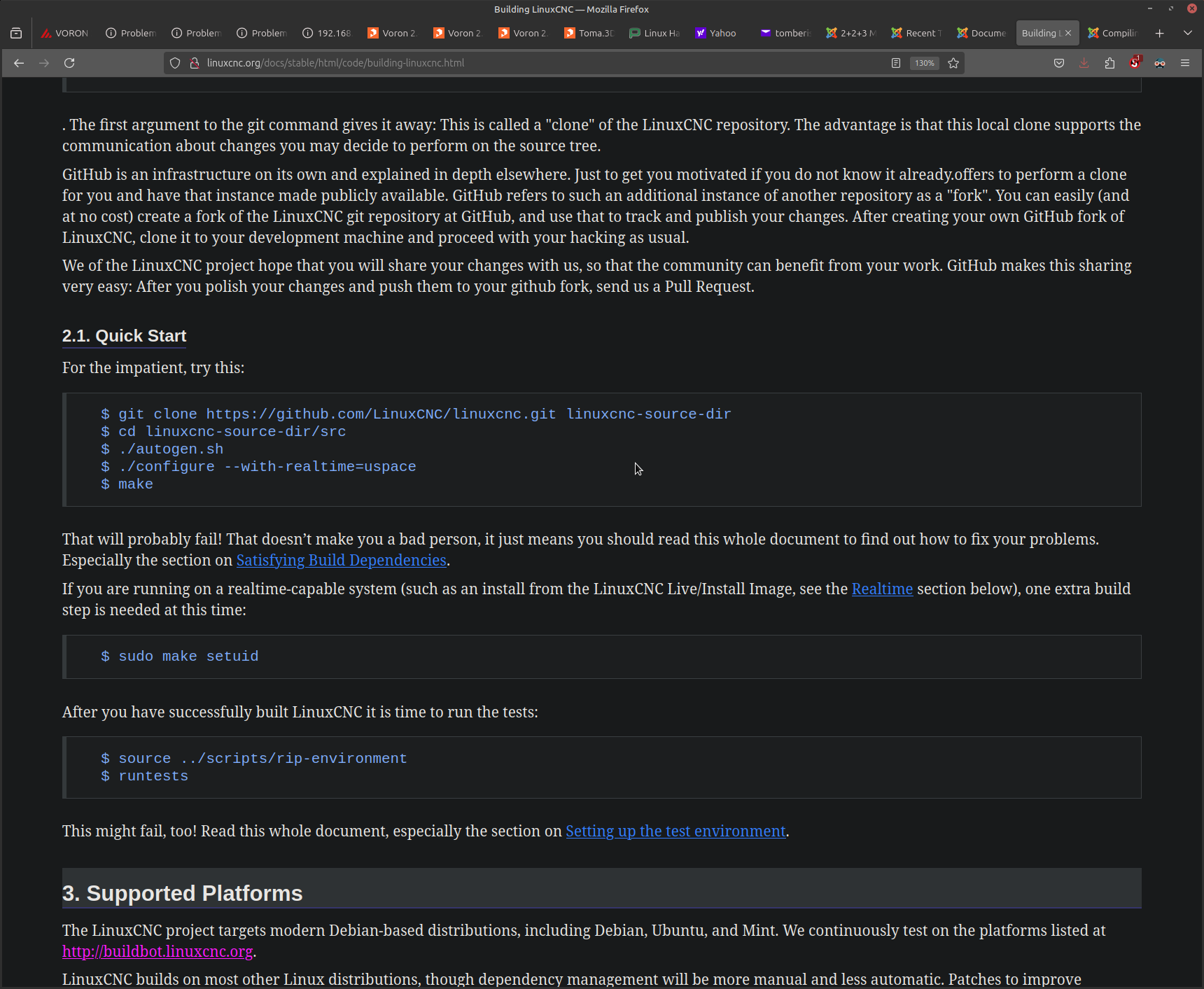

Compiling linuxcnc with source code on Debian12 resulted in an error

Category: Installing LinuxCNC

- yuyu

- yuyu

22 Oct 2024 01:21 - 22 Oct 2024 01:22

- tommylight

22 Oct 2024 01:11 - 22 Oct 2024 01:19

- tommylight

22 Oct 2024 01:06

Replied by tommylight on topic Example of HAL configuration for plasma torch height control with THCAD2 7i96s

Example of HAL configuration for plasma torch height control with THCAD2 7i96s

Category: HAL Examples

- tommylight

22 Oct 2024 00:52

- tommylight

22 Oct 2024 00:48

Replied by tommylight on topic Mesa 7i96s torch on/off connection

Mesa 7i96s torch on/off connection

Category: Driver Boards

- tommylight

22 Oct 2024 00:39

- tommylight

22 Oct 2024 00:33

Replied by tommylight on topic linuxcnc-esp32 Software Stepping over Ethernet Using ESP32

linuxcnc-esp32 Software Stepping over Ethernet Using ESP32

Category: Computers and Hardware

- okielaxplyr

- okielaxplyr

22 Oct 2024 00:18 - 22 Oct 2024 00:26

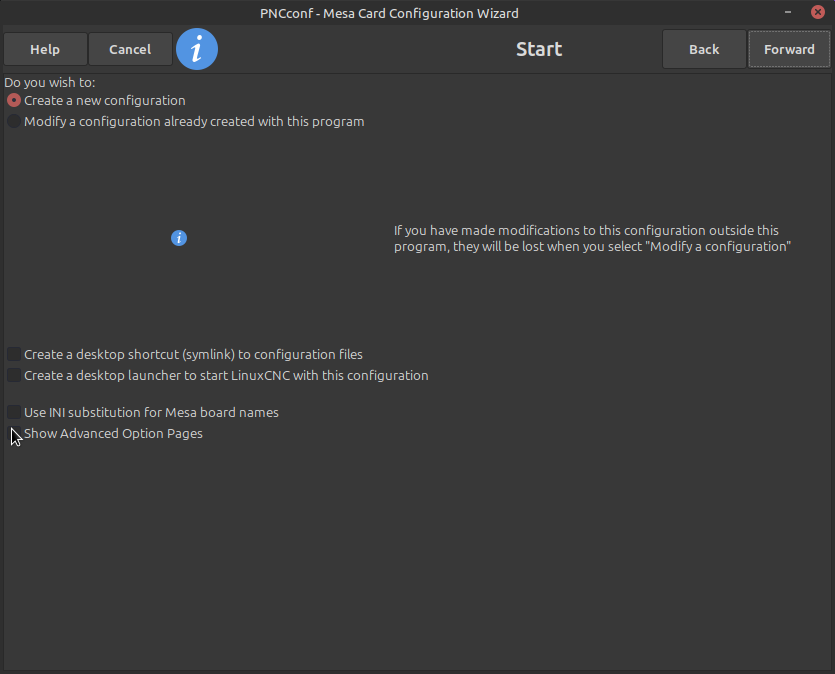

Replied by okielaxplyr on topic PNCconfig error

PNCconfig error

Category: General LinuxCNC Questions

- ric812

- ric812

21 Oct 2024 23:51

Replied by ric812 on topic Mesa 7i96s torch on/off connection

Mesa 7i96s torch on/off connection

Category: Driver Boards

- tommylight

21 Oct 2024 23:21

Replied by tommylight on topic Mesa 7i77 + 5I25T Configuration Issues

Mesa 7i77 + 5I25T Configuration Issues

Category: Driver Boards

- digiex_chris

- digiex_chris

21 Oct 2024 23:18

Surface Grinder cnc conversion advise was created by digiex_chris

Surface Grinder cnc conversion advise

Category: General LinuxCNC Questions

- tommylight

21 Oct 2024 23:15

Replied by tommylight on topic Knuth Mark Super CNC Retrofit - need some help with my first LinuxCNC

Knuth Mark Super CNC Retrofit - need some help with my first LinuxCNC

Category: Milling Machines

- zmrdko

21 Oct 2024 23:13

Replied by zmrdko on topic M6 remap with tool_touch_off.ngc causing gcode parser to fail

M6 remap with tool_touch_off.ngc causing gcode parser to fail

Category: QtPyVCP

- PCW

21 Oct 2024 22:59

Replied by PCW on topic Mesa 7i77 + 5I25T Configuration Issues

Mesa 7i77 + 5I25T Configuration Issues

Category: Driver Boards

Time to create page: 0.434 seconds