Search Results (Searched for: )

- PhilipME

04 Oct 2024 06:42 - 04 Oct 2024 06:51

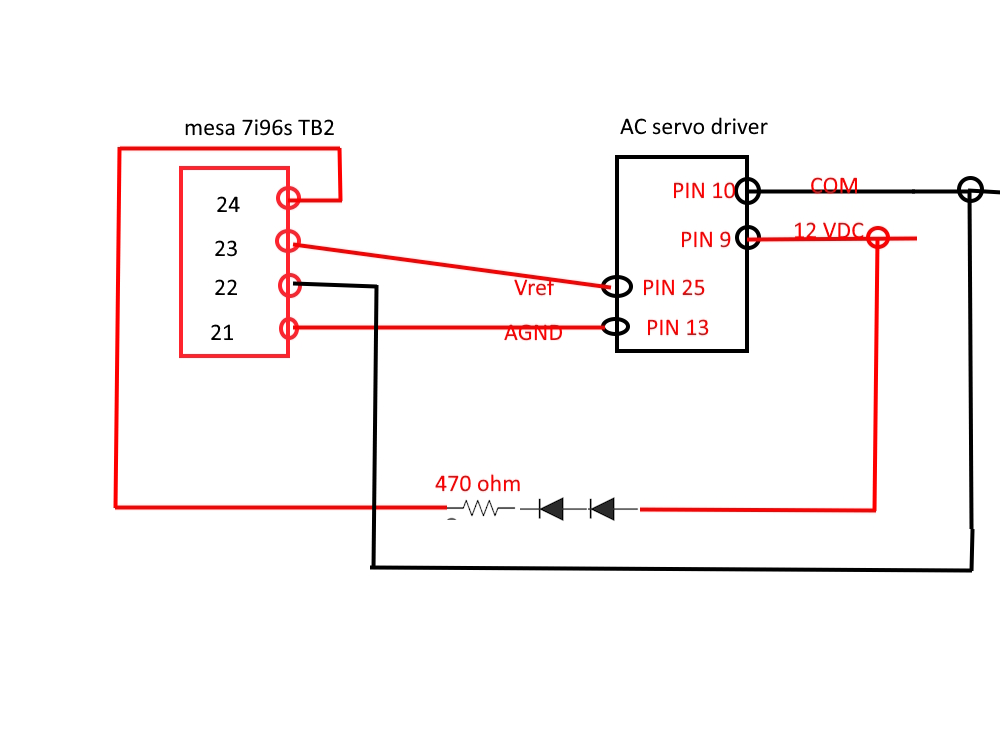

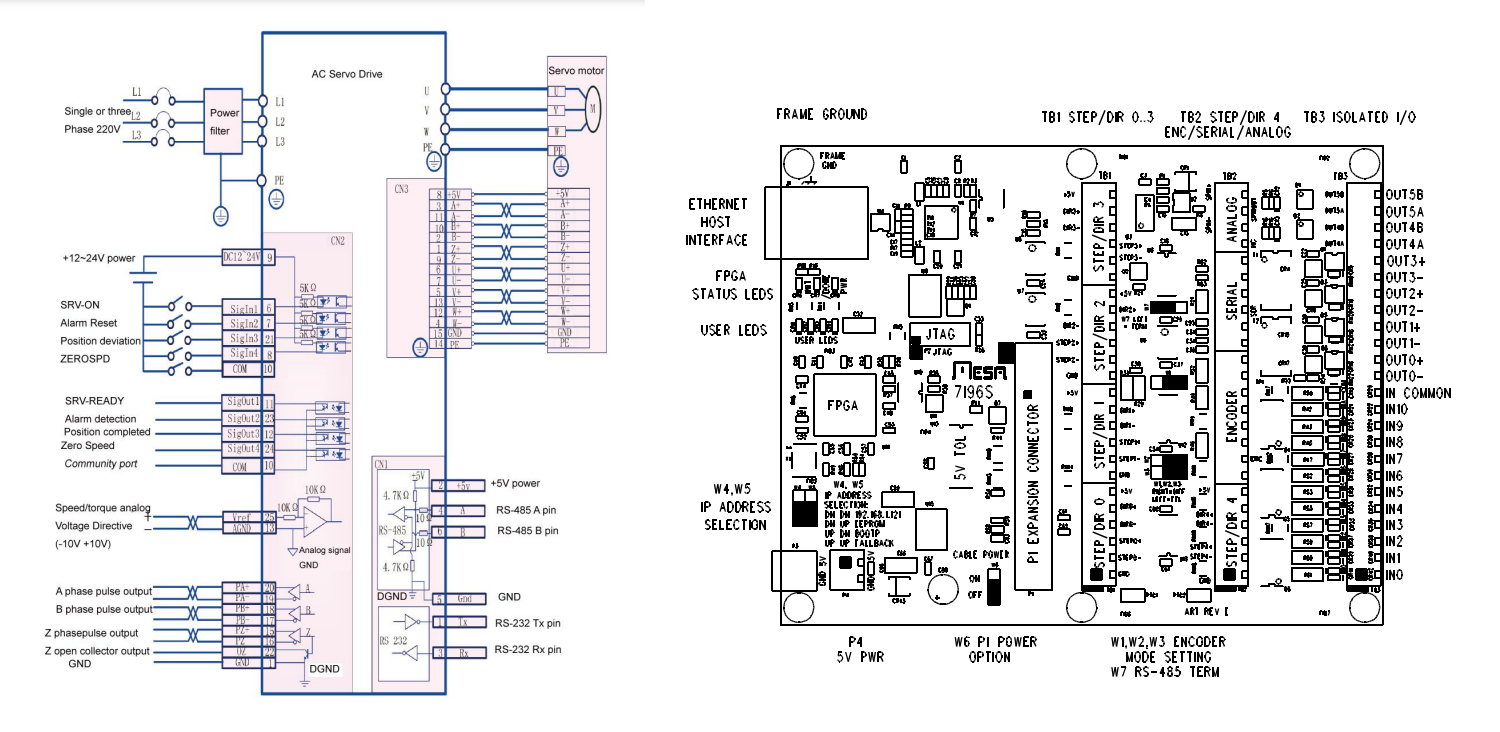

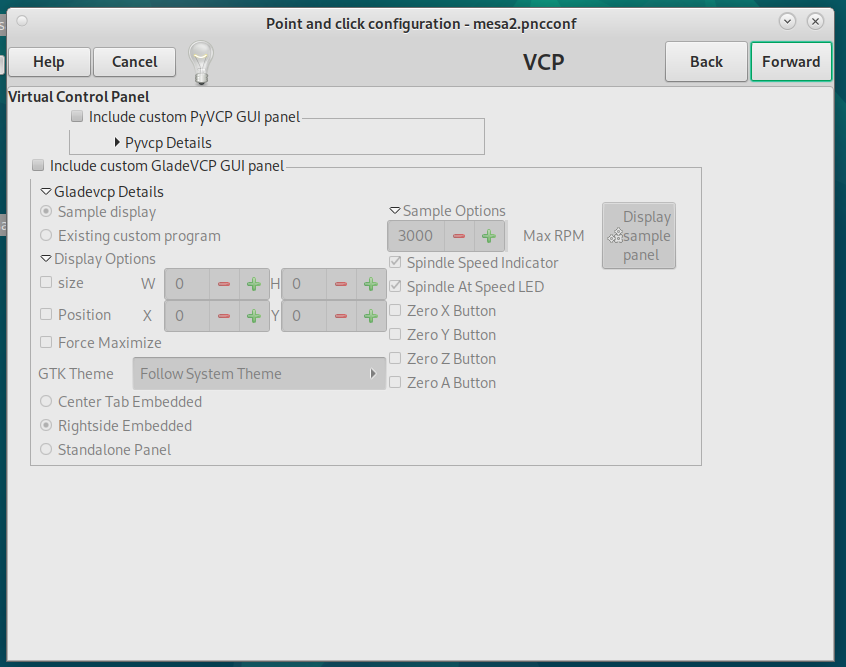

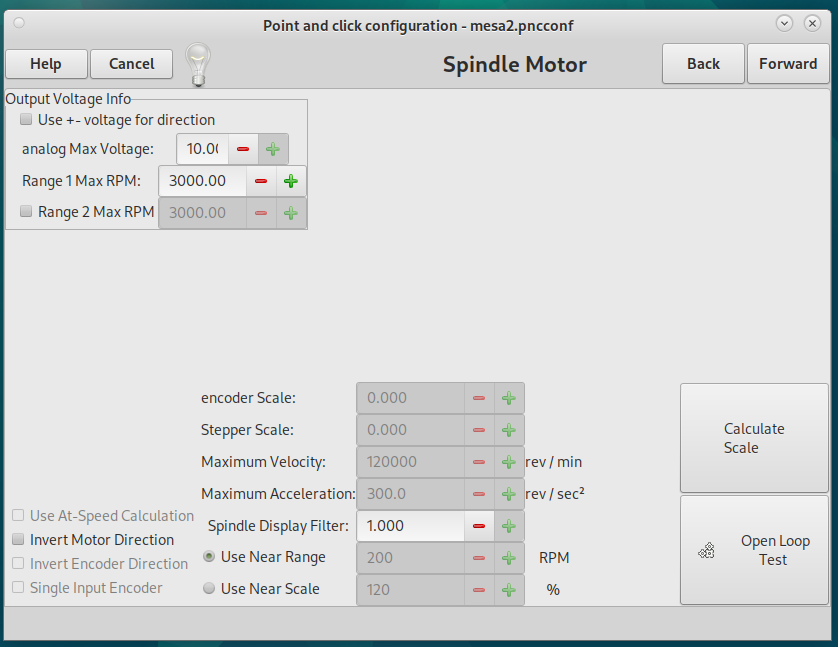

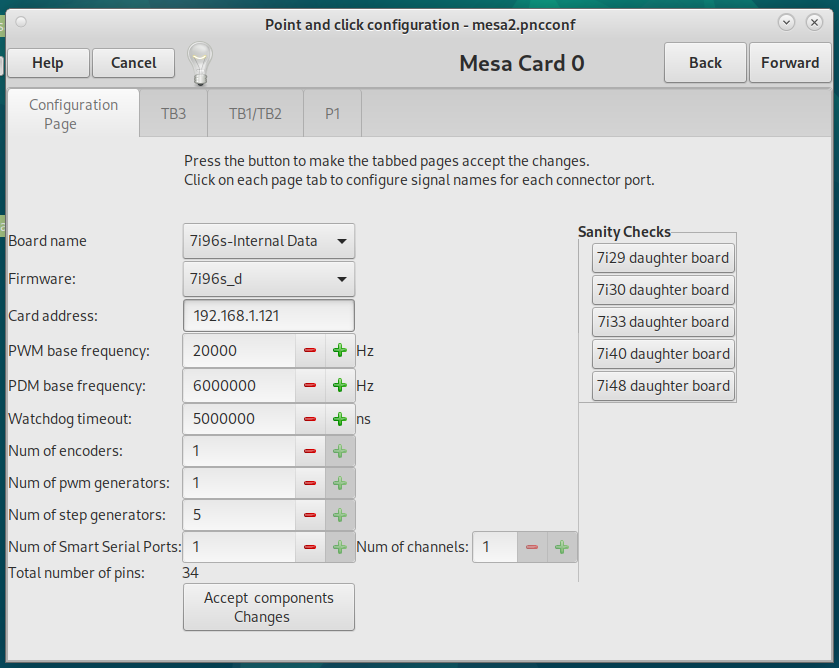

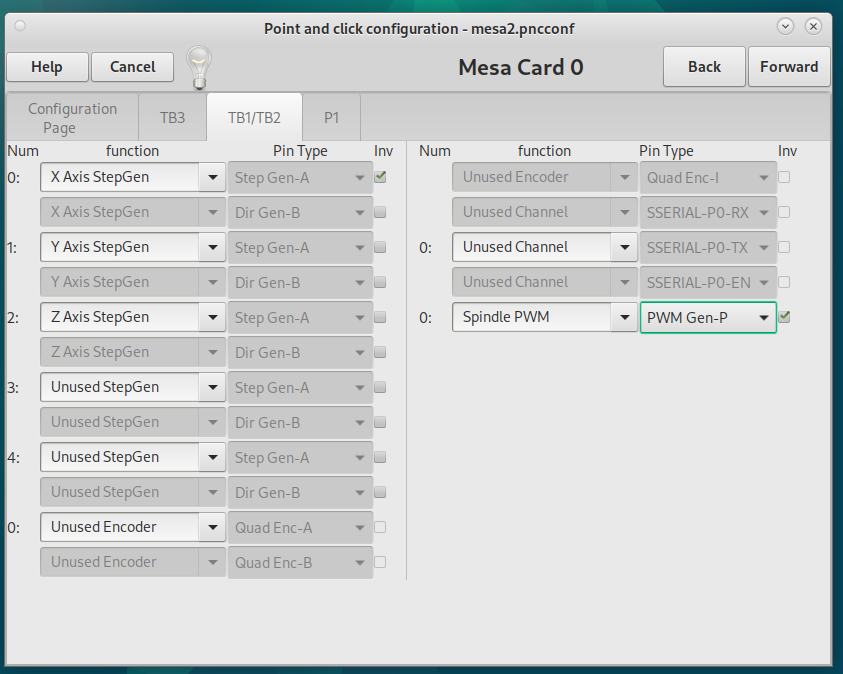

Replied by PhilipME on topic help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21

help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21

Category: PnCConf Wizard

- Aciera

04 Oct 2024 06:12 - 04 Oct 2024 06:17

Replied by Aciera on topic Struggling with custom kinematics...

Struggling with custom kinematics...

Category: Advanced Configuration

- cmorley

- cmorley

04 Oct 2024 04:20

- PhilipME

04 Oct 2024 03:36 - 04 Oct 2024 03:42

Replied by PhilipME on topic help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21

help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21

Category: PnCConf Wizard

- PhilipME

04 Oct 2024 03:32 - 04 Oct 2024 04:14

help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21 was created by PhilipME

help-no voltage across mesa 7i96s spindle TB-2 pins 23 and 21

Category: PnCConf Wizard

- PCW

04 Oct 2024 03:11 - 04 Oct 2024 03:17

Replied by PCW on topic Joint homing offset and following error - HELP

Joint homing offset and following error - HELP

Category: General LinuxCNC Questions

- dreBird

- dreBird

04 Oct 2024 02:40

Joint homing offset and following error - HELP was created by dreBird

Joint homing offset and following error - HELP

Category: General LinuxCNC Questions

- kworm

- kworm

04 Oct 2024 02:14

- kworm

- kworm

04 Oct 2024 02:10

Replied by kworm on topic Weird jogging issue - banging noise

Weird jogging issue - banging noise

Category: General LinuxCNC Questions

- PCW

04 Oct 2024 01:42

Replied by PCW on topic Ye old *axis following error...

Ye old *axis following error...

Category: General LinuxCNC Questions

- snowgoer540

03 Oct 2024 23:53

Replied by snowgoer540 on topic Weird jogging issue - banging noise

Weird jogging issue - banging noise

Category: General LinuxCNC Questions

- M4MazakUser

- M4MazakUser

03 Oct 2024 23:32

Replied by M4MazakUser on topic Ye old *axis following error...

Ye old *axis following error...

Category: General LinuxCNC Questions

- Lcvette

03 Oct 2024 22:22

Replied by Lcvette on topic Probe Basic ATC Setup Problems

Probe Basic ATC Setup Problems

Category: QtPyVCP

- Lcvette

03 Oct 2024 22:21

Replied by Lcvette on topic Probe Basic ATC Setup Problems

Probe Basic ATC Setup Problems

Category: QtPyVCP

- travis036

03 Oct 2024 21:16

Replied by travis036 on topic possible bug with "M66 P26 L4 Q7"? or my use of it? or with FlexGUI?

possible bug with "M66 P26 L4 Q7"? or my use of it? or with FlexGUI?

Category: O Codes (subroutines) and NGCGUI

Time to create page: 0.615 seconds