Search Results (Searched for: )

- adaoferre

- adaoferre

27 Sep 2024 22:23

Replied by adaoferre on topic PWM/frequency signal as input to Mesa card

PWM/frequency signal as input to Mesa card

Category: Driver Boards

- PCW

27 Sep 2024 22:18 - 27 Sep 2024 22:20

Replied by PCW on topic Constant loss of position

Constant loss of position

Category: General LinuxCNC Questions

- adaoferre

- adaoferre

27 Sep 2024 22:16

Replied by adaoferre on topic PWM/frequency signal as input to Mesa card

PWM/frequency signal as input to Mesa card

Category: Driver Boards

- tommylight

27 Sep 2024 22:10

Replied by tommylight on topic Constant loss of position

Constant loss of position

Category: General LinuxCNC Questions

- andreabonuc

- andreabonuc

27 Sep 2024 21:52

Replied by andreabonuc on topic Constant loss of position

Constant loss of position

Category: General LinuxCNC Questions

- PCW

27 Sep 2024 21:13

- nartburg

- nartburg

27 Sep 2024 21:07

Replied by nartburg on topic Mesa 7i96s pktUAT on P1

Mesa 7i96s pktUAT on P1

Category: Driver Boards

- chelgesen

- chelgesen

27 Sep 2024 20:57 - 27 Sep 2024 21:00

Probe Basic tool setter - small unexpected offset was created by chelgesen

Probe Basic tool setter - small unexpected offset

Category: QtPyVCP

- PCW

27 Sep 2024 18:57

- PCW

27 Sep 2024 18:51 - 27 Sep 2024 19:25

- FPM

- FPM

27 Sep 2024 18:21

Replied by FPM on topic converting a tos/intos fngj 40

converting a tos/intos fngj 40

Category: Milling Machines

- MaHa

- MaHa

27 Sep 2024 18:06

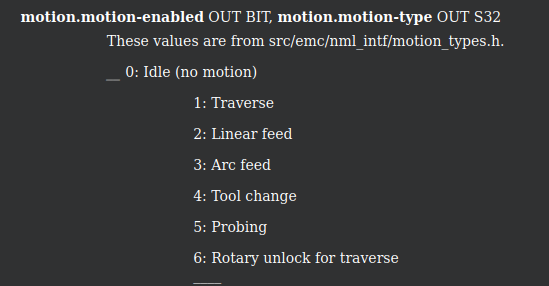

Replied by MaHa on topic HAL pin to indicate motion or pgm running ?

HAL pin to indicate motion or pgm running ?

Category: HAL

- nartburg

- nartburg

27 Sep 2024 18:03

Replied by nartburg on topic Mesa 7i96s pktUAT on P1

Mesa 7i96s pktUAT on P1

Category: Driver Boards

- PCW

27 Sep 2024 17:43

- Aciera

27 Sep 2024 17:28

Replied by Aciera on topic HAL pin to indicate motion or pgm running ?

HAL pin to indicate motion or pgm running ?

Category: HAL

Time to create page: 0.780 seconds