Search Results (Searched for: )

- abdulasis12

- abdulasis12

04 Sep 2024 16:54 - 04 Sep 2024 16:55

Replied by abdulasis12 on topic 7i77 TTL encoder

7i77 TTL encoder

Category: General LinuxCNC Questions

- PCW

04 Sep 2024 16:46

Replied by PCW on topic Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Category: Basic Configuration

- greg23_78

- greg23_78

04 Sep 2024 16:43 - 04 Sep 2024 16:49

- xaxexa

04 Sep 2024 16:35

- aDm1N

04 Sep 2024 16:27 - 04 Sep 2024 19:09

Replied by aDm1N on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- greg23_78

- greg23_78

04 Sep 2024 16:27

Replied by greg23_78 on topic o-codes and ngc file

o-codes and ngc file

Category: Basic Configuration

- pietxs

- pietxs

04 Sep 2024 16:18

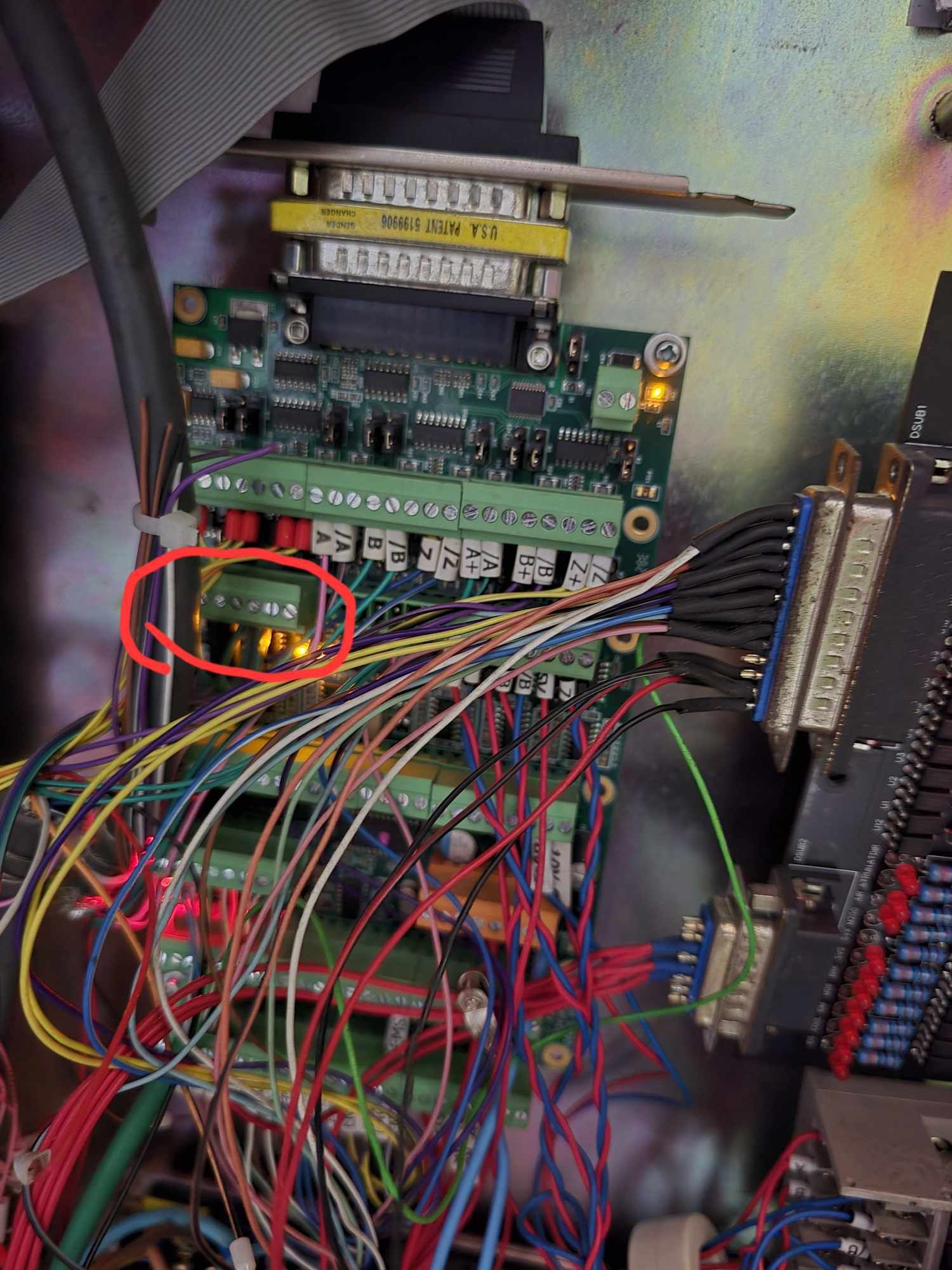

Replied by pietxs on topic Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Category: Basic Configuration

- PCW

04 Sep 2024 15:43

Replied by PCW on topic Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Category: Basic Configuration

- PCW

04 Sep 2024 14:40

- Freak

- Freak

04 Sep 2024 14:40

- mighty_mick

04 Sep 2024 14:37

Replied by mighty_mick on topic What does CMM machines use in software

What does CMM machines use in software

Category: General LinuxCNC Questions

- pietxs

- pietxs

04 Sep 2024 14:32

Replied by pietxs on topic Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Category: Basic Configuration

- Moutomation

- Moutomation

04 Sep 2024 13:59

- PCW

04 Sep 2024 13:41

Replied by PCW on topic Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Maho MH-C 700P Achsen bewegen sich dauerhaft Indramat 3TRM2

Category: Basic Configuration

- PCW

04 Sep 2024 13:37

Time to create page: 0.525 seconds