Search Results (Searched for: )

- oddwick

20 May 2025 18:55

Replied by oddwick on topic [SOLVED] MesaCT problems with 7i96 pwm spindle

[SOLVED] MesaCT problems with 7i96 pwm spindle

Category: Configuration Tools

- tommylight

20 May 2025 18:42

Replied by tommylight on topic [SOLVED] MesaCT problems with 7i96 pwm spindle

[SOLVED] MesaCT problems with 7i96 pwm spindle

Category: Configuration Tools

- PCW

20 May 2025 18:41

Replied by PCW on topic [SOLVED] MesaCT problems with 7i96 pwm spindle

[SOLVED] MesaCT problems with 7i96 pwm spindle

Category: Configuration Tools

- Aciera

20 May 2025 18:39

Replied by Aciera on topic Calling next subroutine messes up offsets

Calling next subroutine messes up offsets

Category: General LinuxCNC Questions

- Hastrh2o

- Hastrh2o

20 May 2025 18:25

- oddwick

20 May 2025 18:12

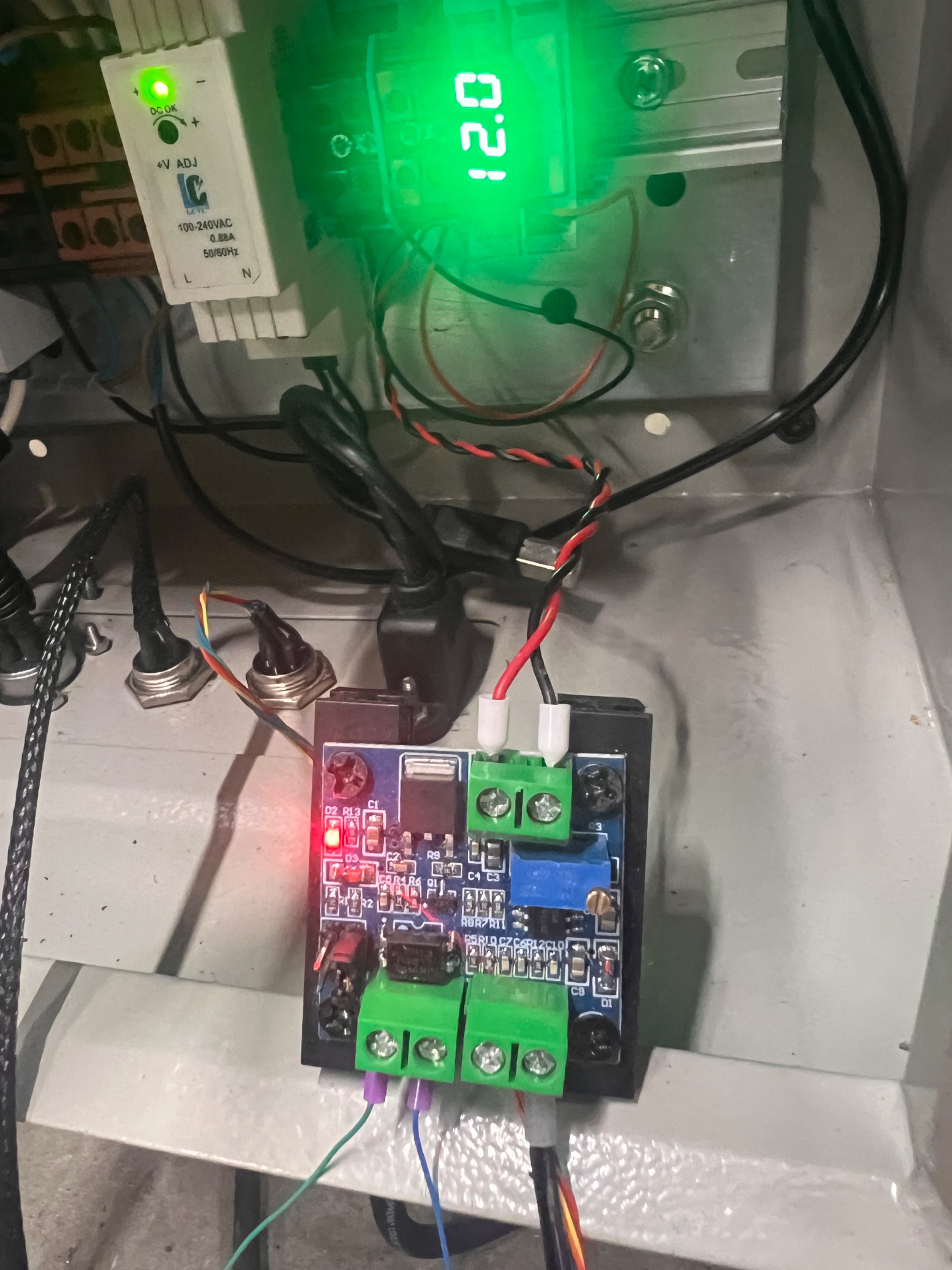

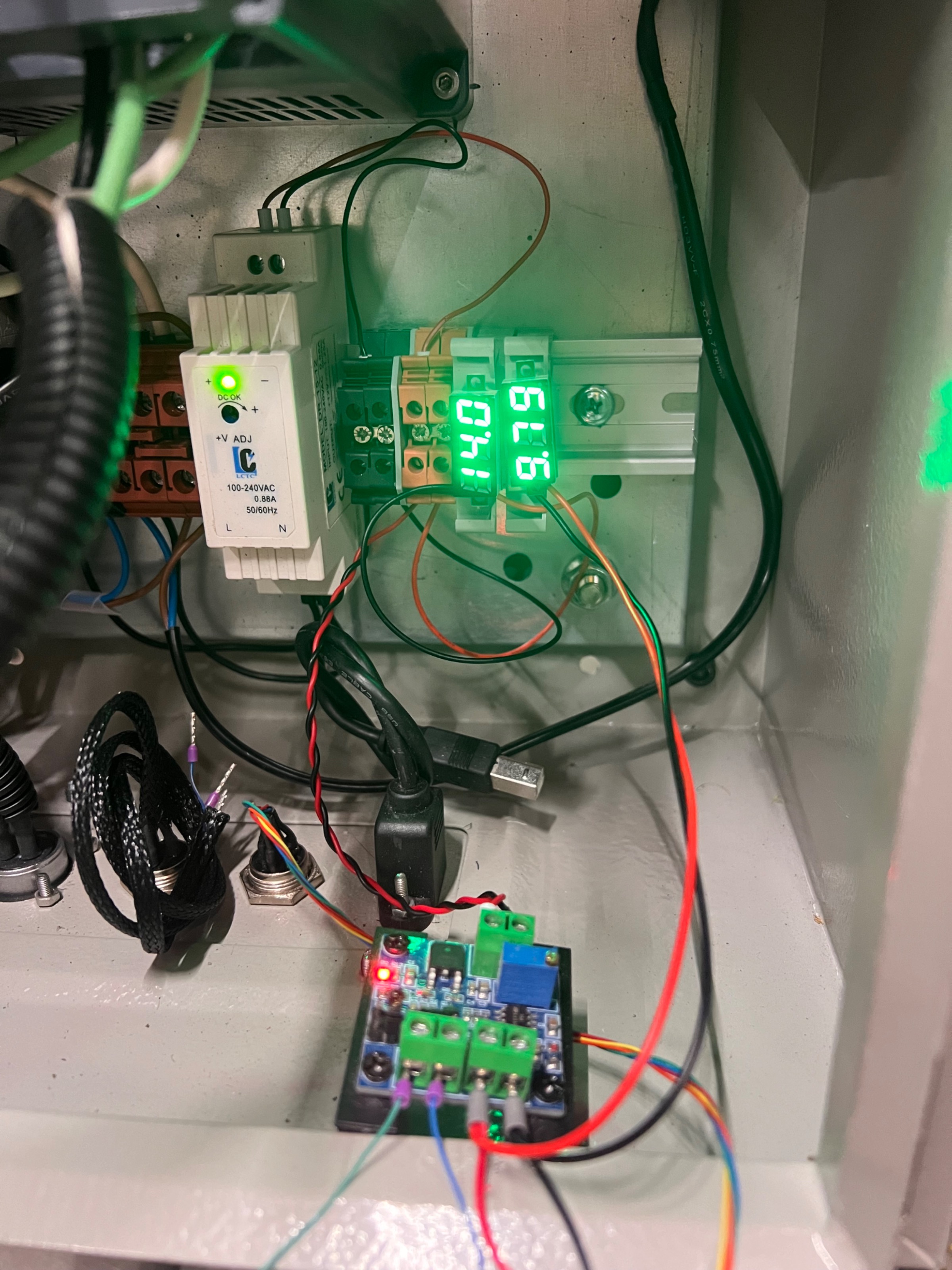

Replied by oddwick on topic [SOLVED] MesaCT problems with 7i96 pwm spindle

[SOLVED] MesaCT problems with 7i96 pwm spindle

Category: Configuration Tools

- langdons

- langdons

20 May 2025 16:58

Replied by langdons on topic Actual position and Commanded position differ, using cia402 [SOLVED]

Actual position and Commanded position differ, using cia402 [SOLVED]

Category: Basic Configuration

- DarkPhoinix

- DarkPhoinix

20 May 2025 16:15 - 20 May 2025 16:28

Replied by DarkPhoinix on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- low-blip

- low-blip

20 May 2025 16:00

Replied by low-blip on topic Actual position and Commanded position differ, using cia402 [SOLVED]

Actual position and Commanded position differ, using cia402 [SOLVED]

Category: Basic Configuration

- low-blip

- low-blip

20 May 2025 15:51

Replied by low-blip on topic Actual position and Commanded position differ, using cia402 [SOLVED]

Actual position and Commanded position differ, using cia402 [SOLVED]

Category: Basic Configuration

- Beovoxo

- Beovoxo

20 May 2025 15:47

- JT

20 May 2025 15:37

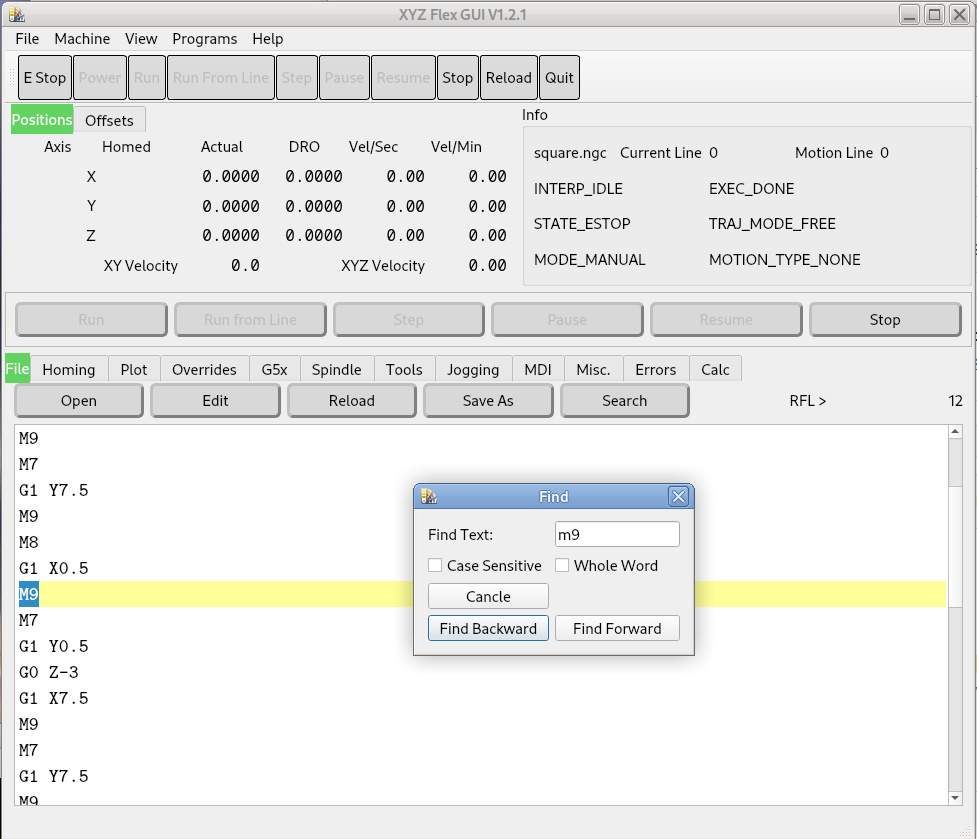

Replied by JT on topic Flex GUI 1.2.1 Released

Flex GUI 1.2.1 Released

Category: Other User Interfaces

- langdons

- langdons

20 May 2025 13:53

Replied by langdons on topic Actual position and Commanded position differ, using cia402 [SOLVED]

Actual position and Commanded position differ, using cia402 [SOLVED]

Category: Basic Configuration

- alangibson

- alangibson

20 May 2025 13:29 - 20 May 2025 13:31

Replied by alangibson on topic Ohmic probe aborts immediately

Ohmic probe aborts immediately

Category: Plasmac

- Routerworks

- Routerworks

20 May 2025 13:22

Replied by Routerworks on topic Calling next subroutine messes up offsets

Calling next subroutine messes up offsets

Category: General LinuxCNC Questions

Time to create page: 0.453 seconds