Search Results (Searched for: )

- Thayloreing

- Thayloreing

18 May 2025 18:14 - 18 May 2025 19:11

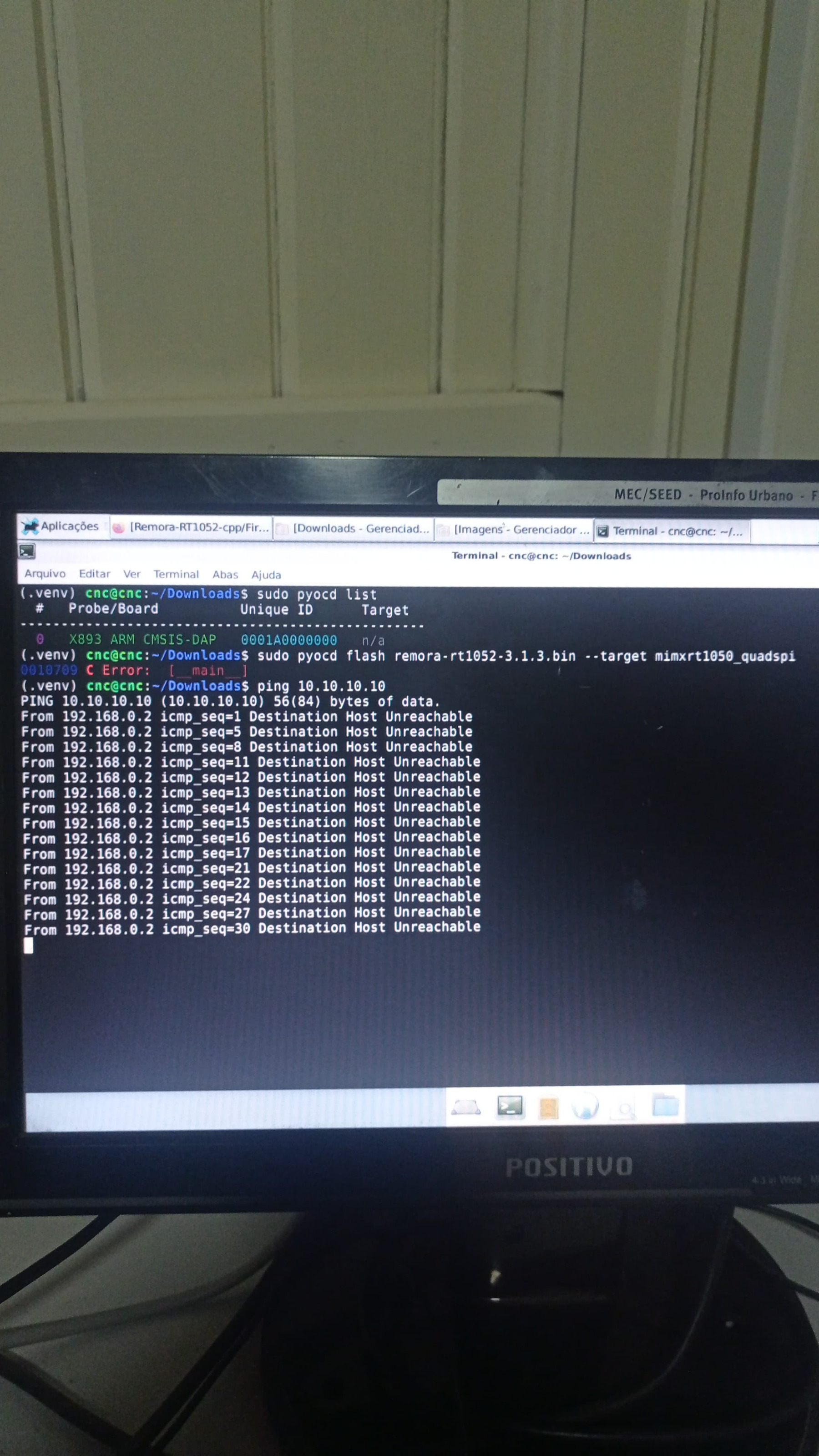

Replied by Thayloreing on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- unknown

- unknown

18 May 2025 17:33

Replied by unknown on topic Linuxcnc 2.9.4 .iso on Rpi5: apt update does not build /boot/initrd.gz

Linuxcnc 2.9.4 .iso on Rpi5: apt update does not build /boot/initrd.gz

Category: Installing LinuxCNC

- unknown

- unknown

18 May 2025 17:27

Replied by unknown on topic Important Info Regarding Rpi4/5 Images.

Important Info Regarding Rpi4/5 Images.

Category: Computers and Hardware

- Murphy

- Murphy

18 May 2025 17:10

Replied by Murphy on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- rdtsc

18 May 2025 16:37

- pgf

- pgf

18 May 2025 16:35

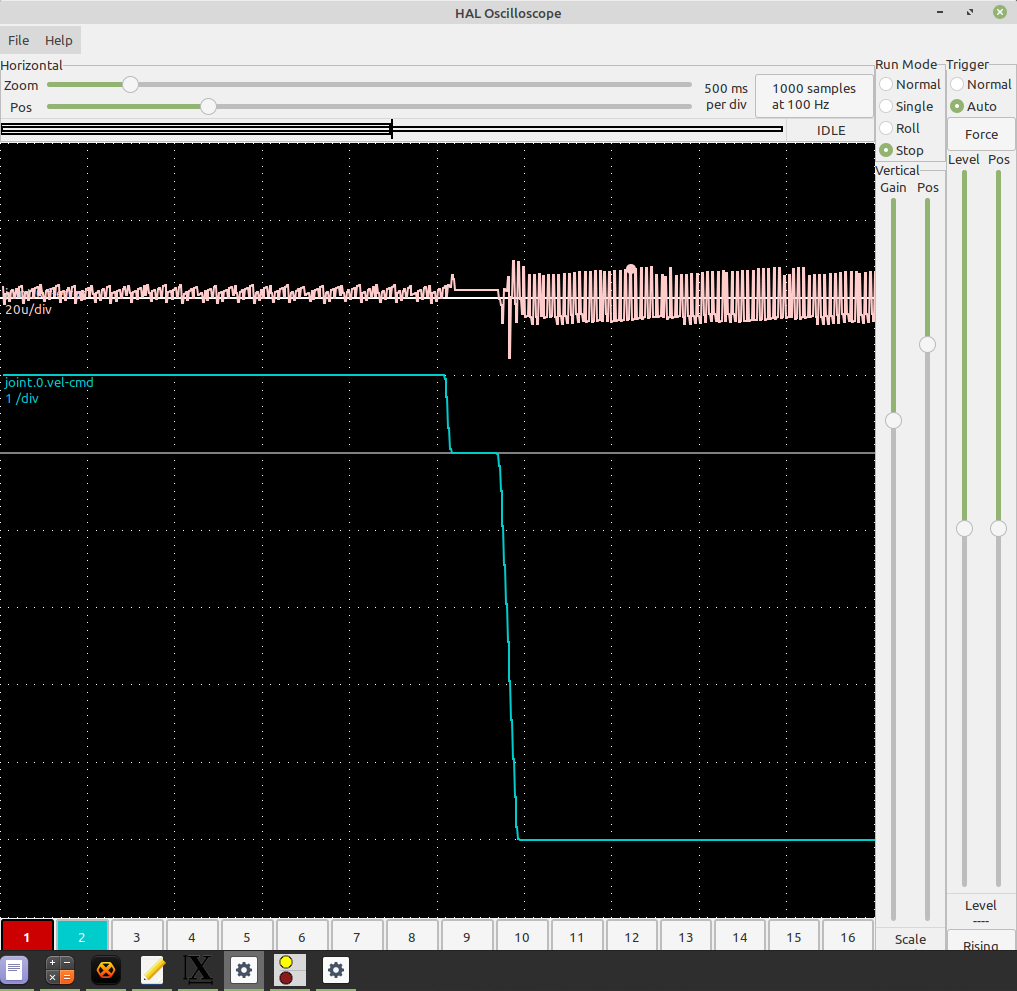

Replied by pgf on topic Effect of lengthening the servo thread period?

Effect of lengthening the servo thread period?

Category: Basic Configuration

- langdons

- langdons

18 May 2025 16:12 - 20 May 2025 00:16

Replied by langdons on topic Important Info Regarding Rpi4/5 Images.

Important Info Regarding Rpi4/5 Images.

Category: Computers and Hardware

- GDTH

18 May 2025 15:58

Probe basic toolchanger was created by GDTH

Probe basic toolchanger

Category: O Codes (subroutines) and NGCGUI

- langdons

- langdons

18 May 2025 15:44

Replied by langdons on topic Ohmic probe aborts immediately

Ohmic probe aborts immediately

Category: Plasmac

- PCW

18 May 2025 14:38

Replied by PCW on topic [SOLVED] MesaCT problems with 7i96 pwm spindle

[SOLVED] MesaCT problems with 7i96 pwm spindle

Category: Configuration Tools

- unknown

- unknown

18 May 2025 14:25

Replied by unknown on topic Why does it seem like everyone here is Australian?

Why does it seem like everyone here is Australian?

Category: Off Topic and Test Posts

- oddwick

18 May 2025 14:24

Replied by oddwick on topic [SOLVED] MesaCT problems with 7i96 pwm spindle

[SOLVED] MesaCT problems with 7i96 pwm spindle

Category: Configuration Tools

- Doc_emmet

- Doc_emmet

18 May 2025 14:15

Replied by Doc_emmet on topic Activate B-axis in Porbe Basic

Activate B-axis in Porbe Basic

Category: QtPyVCP

- PCW

18 May 2025 14:07 - 18 May 2025 14:09

Replied by PCW on topic Effect of lengthening the servo thread period?

Effect of lengthening the servo thread period?

Category: Basic Configuration

- Giovanni

- Giovanni

18 May 2025 13:32

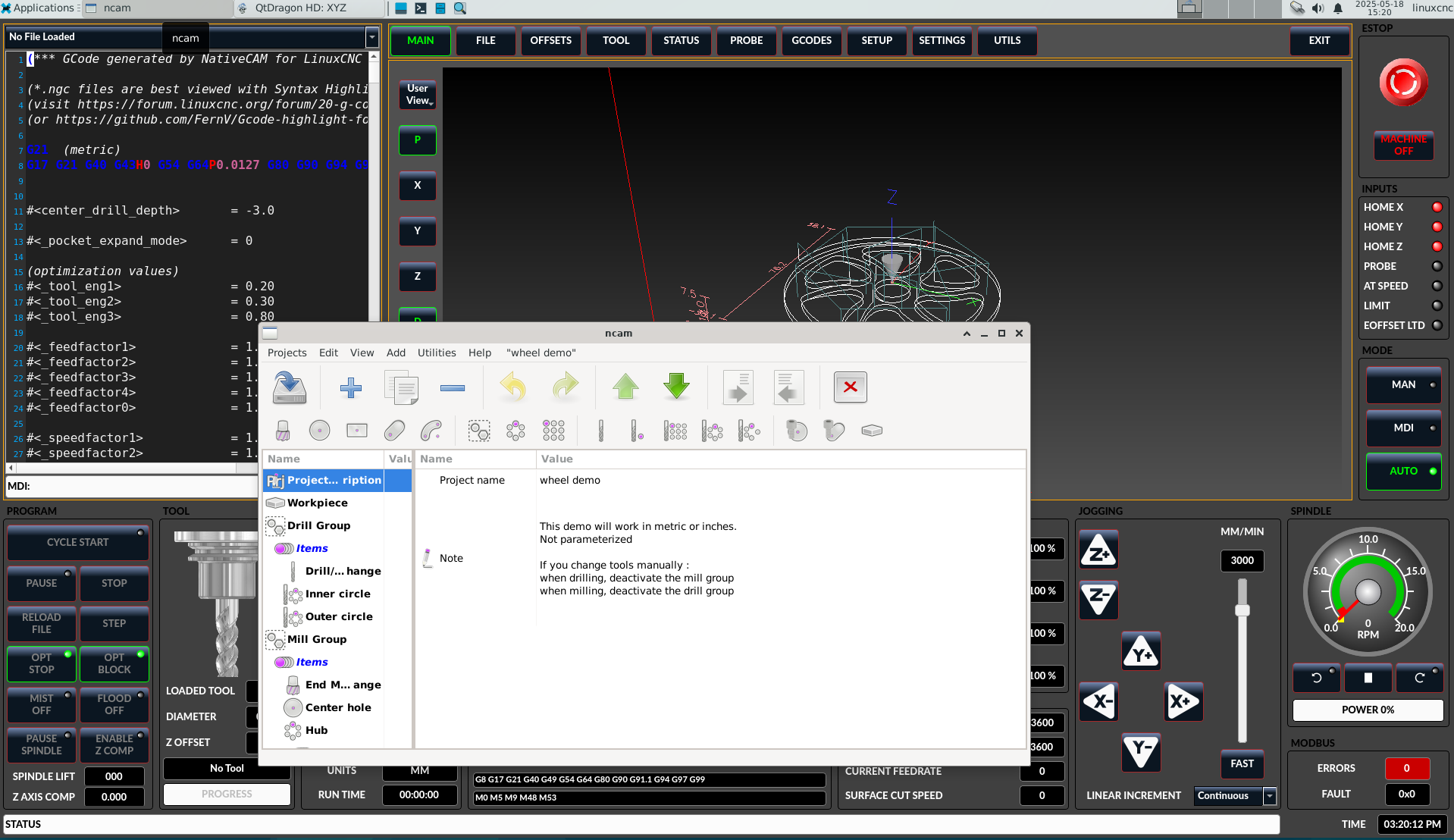

Replied by Giovanni on topic NativeCam on LinuxCNC 2.9.3

NativeCam on LinuxCNC 2.9.3

Category: NativeCAM

Time to create page: 0.974 seconds