Search Results (Searched for: )

- bobwolf

- bobwolf

29 Jan 2026 21:11

Replied by bobwolf on topic Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Category: Driver Boards

- IndeeSales

29 Jan 2026 21:05

Replied by IndeeSales on topic Ethercat Leadshine L6N Gantry XYYZ Config

Ethercat Leadshine L6N Gantry XYYZ Config

Category: EtherCAT

- Muftijaja

- Muftijaja

29 Jan 2026 20:58

Replied by Muftijaja on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- Muftijaja

- Muftijaja

29 Jan 2026 20:54

Replied by Muftijaja on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- bobwolf

- bobwolf

29 Jan 2026 20:52

Replied by bobwolf on topic Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Category: Driver Boards

- Will_cnc

- Will_cnc

29 Jan 2026 20:51

Issues setting up Tool setter / manual tool change was created by Will_cnc

Issues setting up Tool setter / manual tool change

Category: QtPyVCP

- bobwolf

- bobwolf

29 Jan 2026 20:35

Replied by bobwolf on topic Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Category: Driver Boards

- bobwolf

- bobwolf

29 Jan 2026 20:18 - 29 Jan 2026 20:22

Replied by bobwolf on topic Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Category: Driver Boards

- juliankoenig87

- juliankoenig87

29 Jan 2026 20:14

Replied by juliankoenig87 on topic How can I contact juliankoenig87

How can I contact juliankoenig87

Category: General LinuxCNC Questions

- bobwolf

- bobwolf

29 Jan 2026 20:12

Replied by bobwolf on topic Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Solving the USB Latency Dogma for HMI/MPG: Technical Feedback Request

Category: Driver Boards

- cncfreak

- cncfreak

29 Jan 2026 19:53 - 29 Jan 2026 20:08

- Finngineering

- Finngineering

29 Jan 2026 18:54

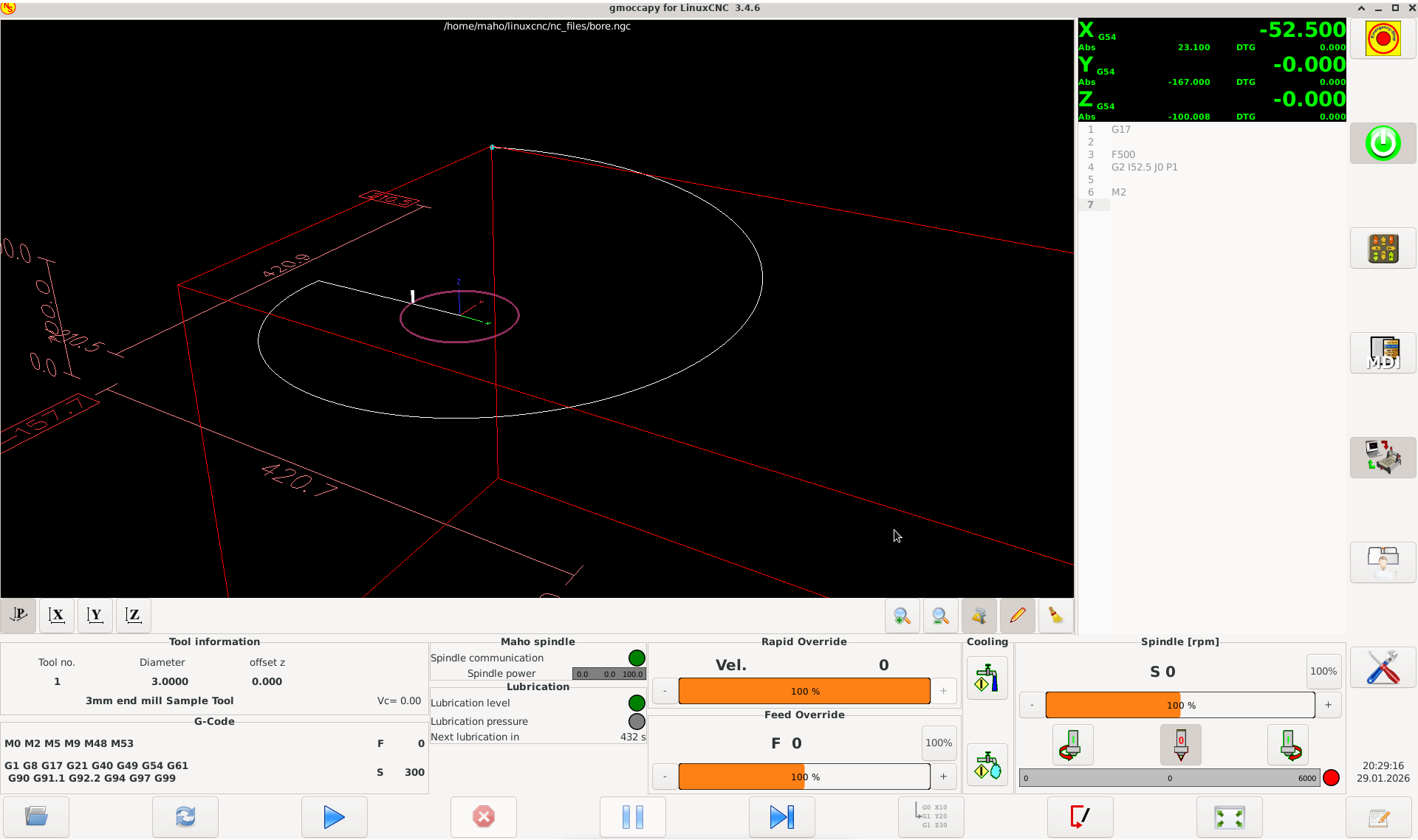

Strange preview for circular arc (G2/G3) was created by Finngineering

Strange preview for circular arc (G2/G3)

Category: G&M Codes

- Marco

- Marco

- endian

29 Jan 2026 17:44

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- PCW

29 Jan 2026 17:43

Replied by PCW on topic Problem with Mesa 7i96s and spindle control

Problem with Mesa 7i96s and spindle control

Category: General LinuxCNC Questions

Time to create page: 0.299 seconds