Search Results (Searched for: )

- Mitch66

- Mitch66

03 Dec 2024 11:26

Replied by Mitch66 on topic Hello (First post), please send me in the right direction

Hello (First post), please send me in the right direction

Category: LinuxCNC Documents

- Ahmed.emara

- Ahmed.emara

03 Dec 2024 11:23

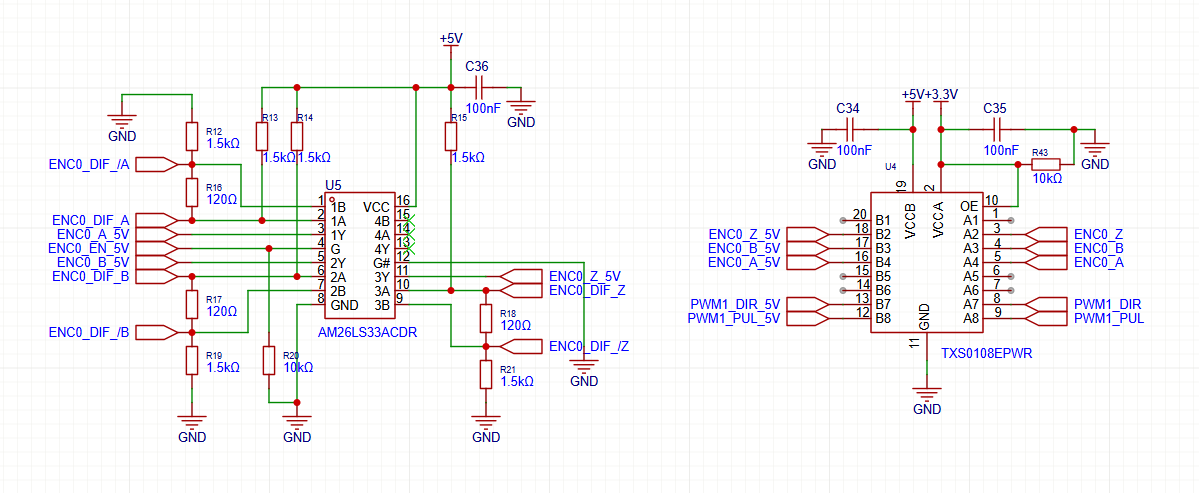

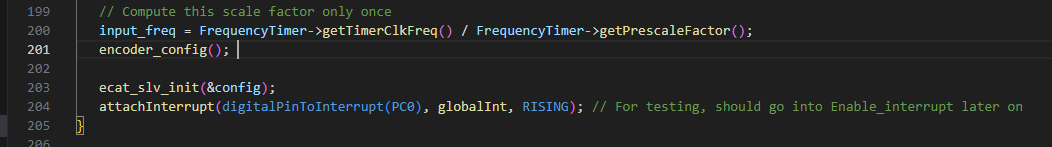

Replied by Ahmed.emara on topic Ethercat + step/dir signals

Ethercat + step/dir signals

Category: EtherCAT

- D Jensen

- D Jensen

03 Dec 2024 11:19

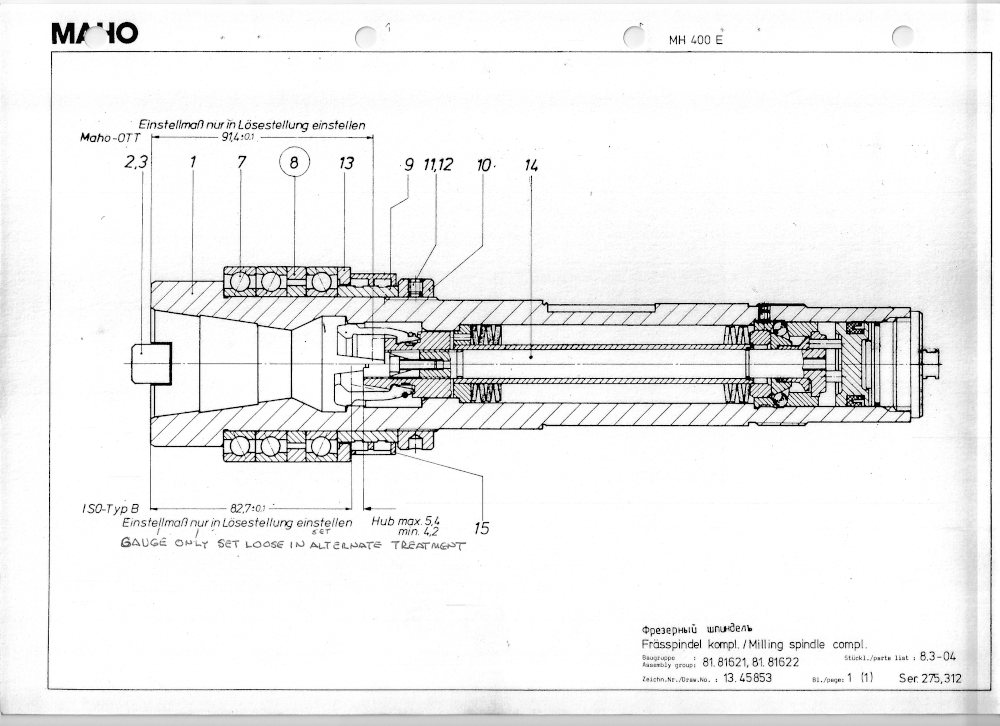

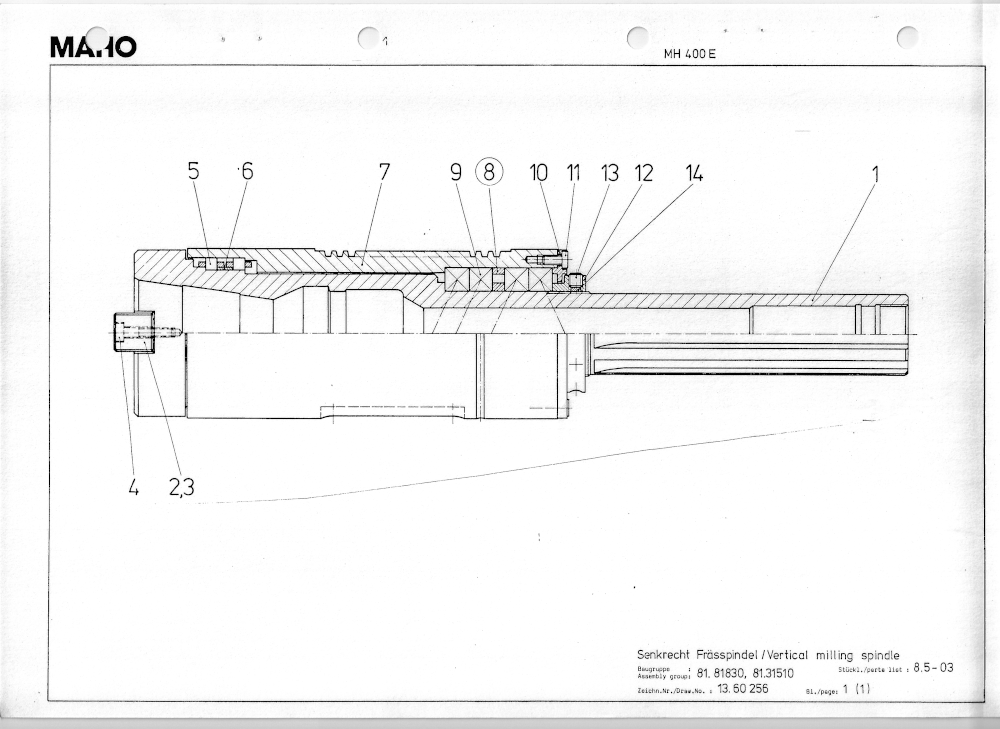

Replied by D Jensen on topic Retrofitting a 1986 Maho 400E

Retrofitting a 1986 Maho 400E

Category: Milling Machines

- Ahmed.emara

- Ahmed.emara

03 Dec 2024 11:18

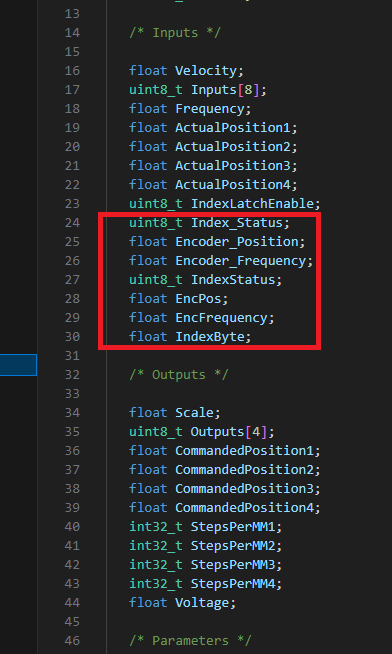

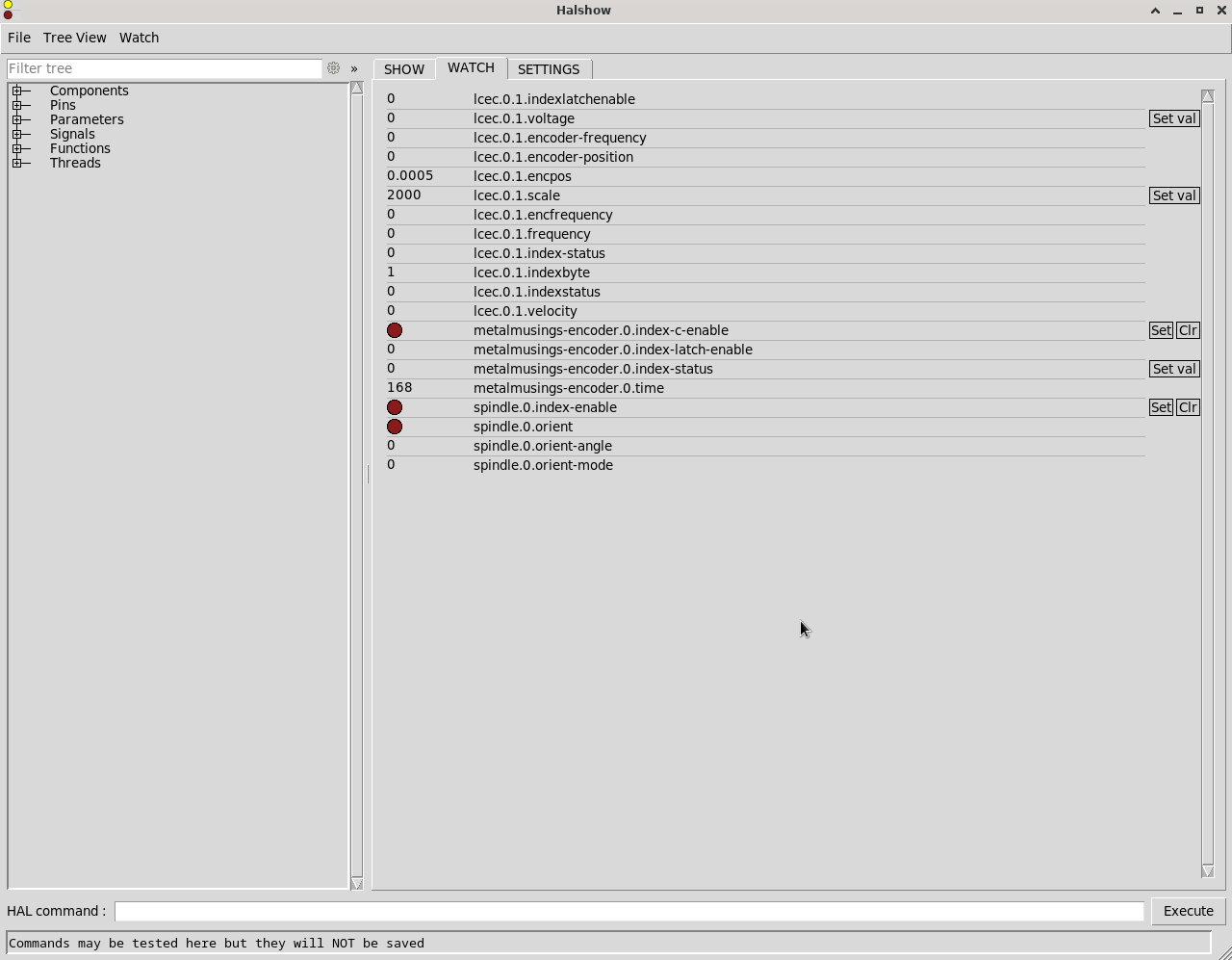

Lichuan Ethercat Nema23 closed loop stepper motor XML configuration was created by Ahmed.emara

Lichuan Ethercat Nema23 closed loop stepper motor XML configuration

Category: EtherCAT

- nigelh

03 Dec 2024 09:48 - 03 Dec 2024 15:11

Wiring Mesa 7i95t inputs in parallel with DRO was created by nigelh

Wiring Mesa 7i95t inputs in parallel with DRO

Category: Basic Configuration

- RotarySMP

03 Dec 2024 09:28

Replied by RotarySMP on topic Retrofitting a 1986 Maho 400E

Retrofitting a 1986 Maho 400E

Category: Milling Machines

- Aciera

03 Dec 2024 08:45

- Hossein74Majidi

- Hossein74Majidi

03 Dec 2024 08:38

Replied by Hossein74Majidi on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

- Hendrixx

- Hendrixx

03 Dec 2024 08:36 - 03 Dec 2024 09:13

Using a Mesa card input to monitor EMI emissions with Halscope was created by Hendrixx

Using a Mesa card input to monitor EMI emissions with Halscope

Category: HAL

- royka

- royka

03 Dec 2024 08:04

Replied by royka on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

Time to create page: 0.565 seconds