Search Results (Searched for: )

- dbtayl

- dbtayl

19 Nov 2024 22:57

- PCW

19 Nov 2024 22:52

Replied by PCW on topic Configuring hardware jog buttons

Configuring hardware jog buttons

Category: HAL

- Sziggy_NC

- Sziggy_NC

19 Nov 2024 22:34

Replied by Sziggy_NC on topic 7i97t Spindle has 0v or 10v

7i97t Spindle has 0v or 10v

Category: General LinuxCNC Questions

- digiex_chris

- digiex_chris

19 Nov 2024 21:41

Replied by digiex_chris on topic Flex Gui forces machine into Manual mode when any other process switches to MDI

Flex Gui forces machine into Manual mode when any other process switches to MDI

Category: Other User Interfaces

- Grotius

19 Nov 2024 21:30

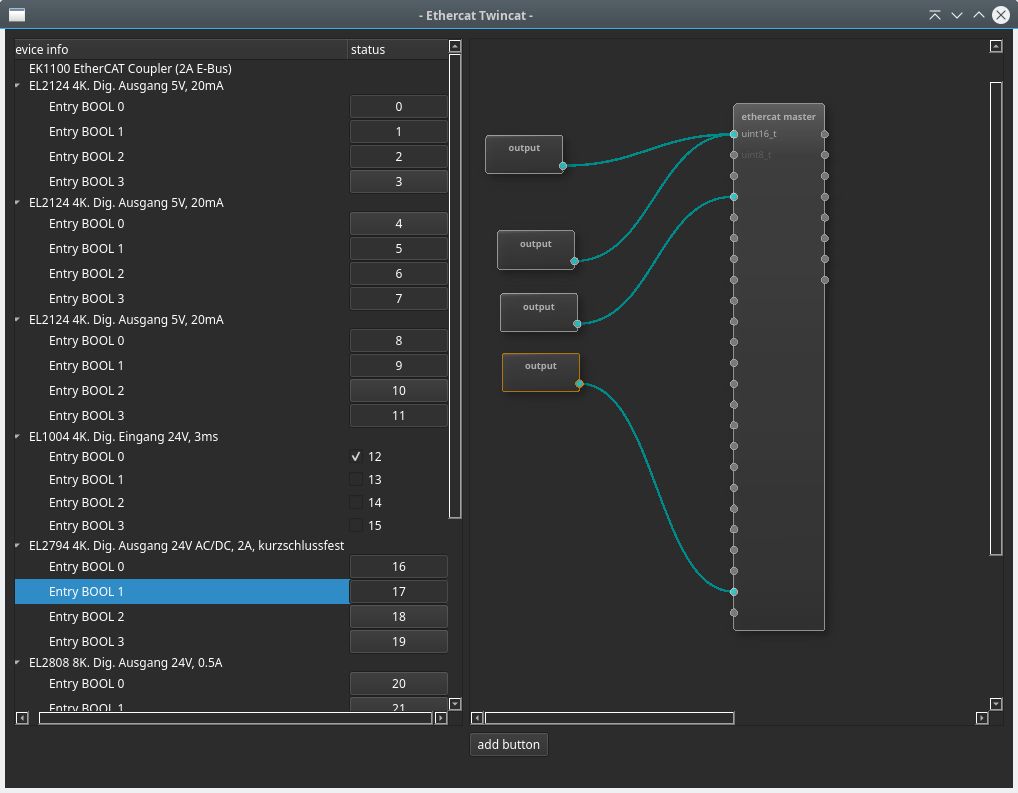

Replied by Grotius on topic Ethercat auto configurator.

Ethercat auto configurator.

Category: EtherCAT

- Unlogic

- Unlogic

19 Nov 2024 21:29

Replied by Unlogic on topic Configuring hardware jog buttons

Configuring hardware jog buttons

Category: HAL

- gardenweazel

19 Nov 2024 21:18 - 19 Nov 2024 21:19

Replied by gardenweazel on topic Inconsistent values from Versaprobe

Inconsistent values from Versaprobe

Category: Qtvcp

- viesturs.lacis

- viesturs.lacis

19 Nov 2024 21:05 - 19 Nov 2024 21:05

Replied by viesturs.lacis on topic Yaskawa incremental encoder and Mesa 7i48

Yaskawa incremental encoder and Mesa 7i48

Category: Driver Boards

- floris

- floris

19 Nov 2024 20:58

Best version for Parport machine and how to install was created by floris

Best version for Parport machine and how to install

Category: Installing LinuxCNC

- Axolito

19 Nov 2024 20:26 - 19 Nov 2024 20:31

Mecanumeric / Charlyrobot retrofit was created by Axolito

Mecanumeric / Charlyrobot retrofit

Category: Show Your Stuff

- scotta

19 Nov 2024 20:03

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- Axolito

19 Nov 2024 19:54

Replied by Axolito on topic Flex GUI translation

Flex GUI translation

Category: Other User Interfaces

- royka

- royka

19 Nov 2024 19:23

Replied by royka on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

- JT

19 Nov 2024 18:32

- CopperHead

- CopperHead

19 Nov 2024 18:23

Time to create page: 0.474 seconds