Search Results (Searched for: )

- tommylight

02 Dec 2025 05:50

Replied by tommylight on topic Remora sk1.4 with ethernet?

Remora sk1.4 with ethernet?

Category: Computers and Hardware

- tommylight

02 Dec 2025 05:46

Replied by tommylight on topic parport observation in outport out-inverter-1 seems not to work

parport observation in outport out-inverter-1 seems not to work

Category: HAL

- rodw

02 Dec 2025 04:48

Replied by rodw on topic User name rpi-first-boot-wizard

User name rpi-first-boot-wizard

Category: Installing LinuxCNC

- PCW

02 Dec 2025 03:32

- COFHAL

- COFHAL

02 Dec 2025 01:49

Replied by COFHAL on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- Z3n

- Z3n

01 Dec 2025 23:25

Replied by Z3n on topic Red Init & Done Lights on 7i92M

Red Init & Done Lights on 7i92M

Category: Driver Boards

- Punisher

- Punisher

01 Dec 2025 22:20 - 05 Dec 2025 02:44

Remora sk1.4 with ethernet? was created by Punisher

Remora sk1.4 with ethernet?

Category: Computers and Hardware

- Steve303

- Steve303

01 Dec 2025 22:06

Replied by Steve303 on topic 4th axis scale factor (steps per degree)

4th axis scale factor (steps per degree)

Category: PathPilot

- EdWorks

01 Dec 2025 22:05

- OHEngineering

01 Dec 2025 21:56

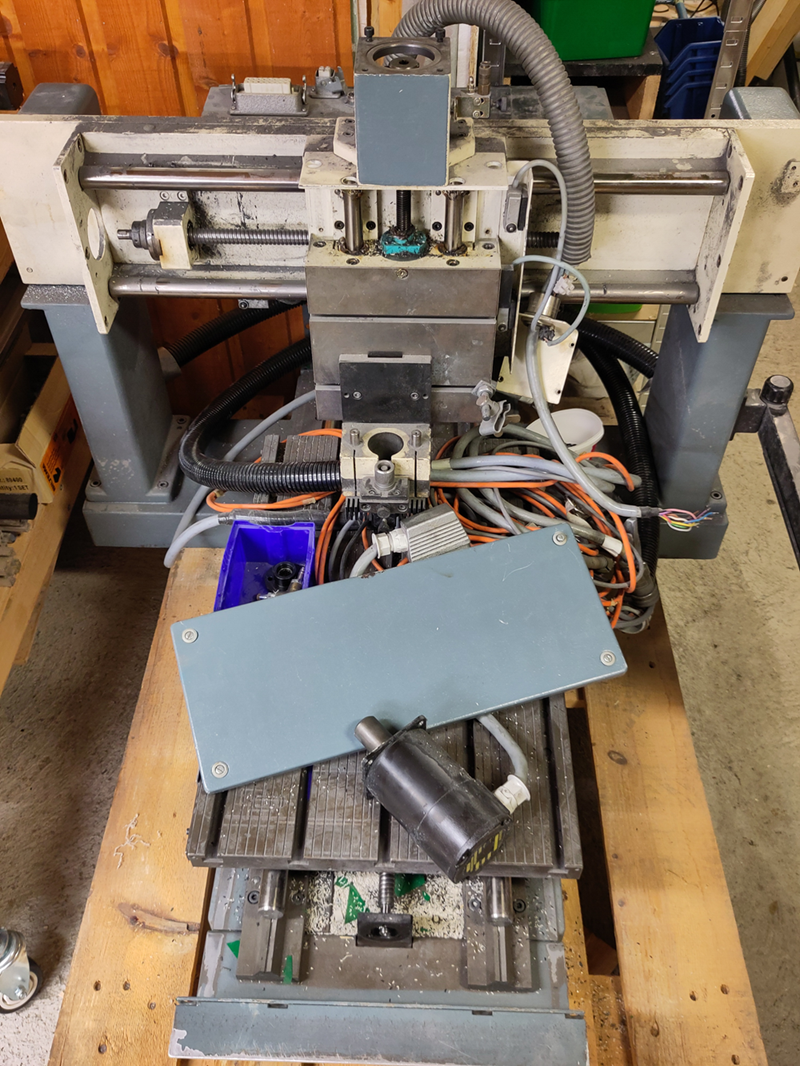

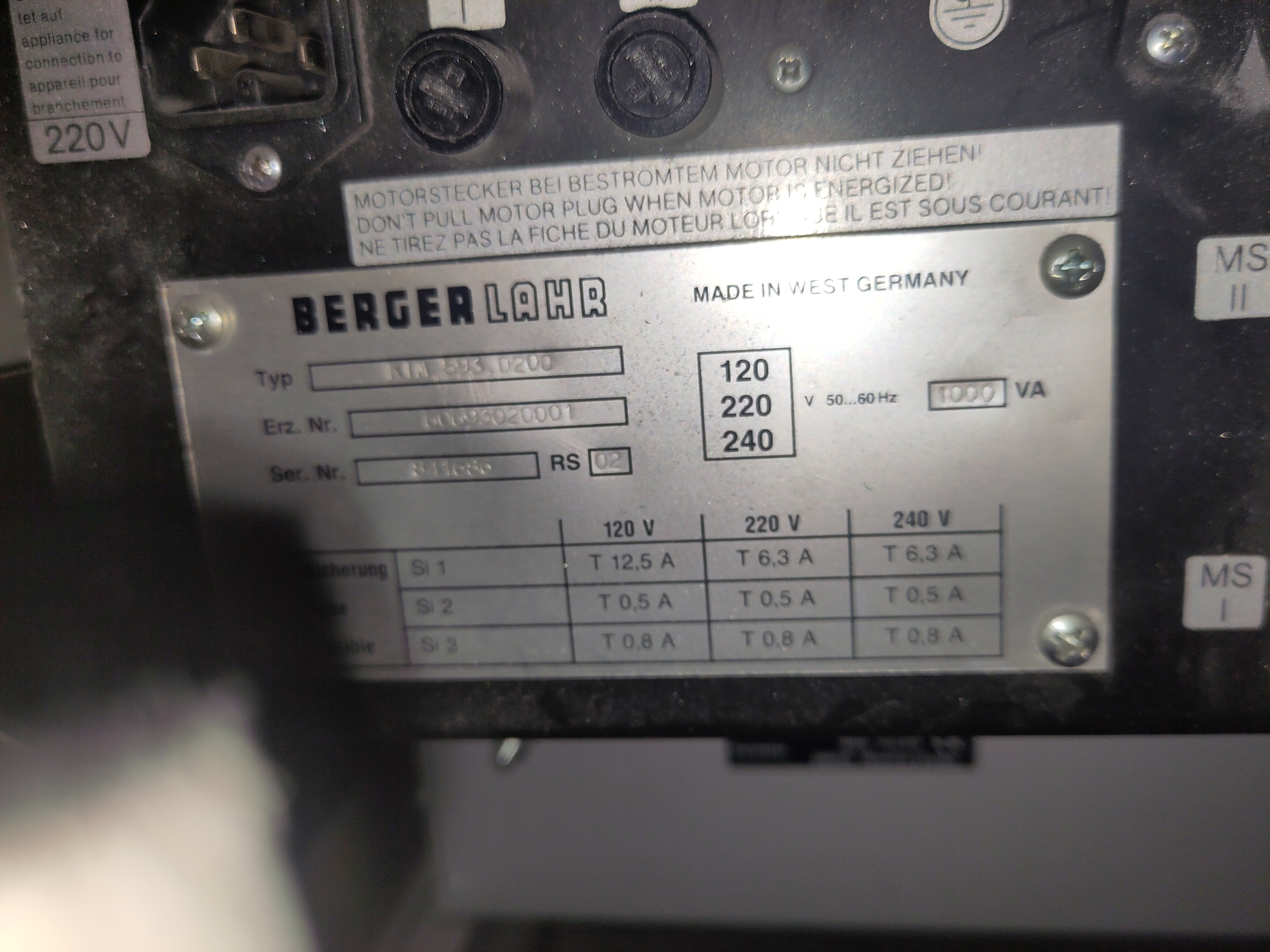

Kuhlmann Engraver/mill retrofit Build log was created by OHEngineering

Kuhlmann Engraver/mill retrofit Build log

Category: Show Your Stuff

- ArthurG

- ArthurG

01 Dec 2025 21:27

Looking for freelancer to finish retrofit of K2 router was created by ArthurG

Looking for freelancer to finish retrofit of K2 router

Category: User Exchange

- Muzzer

- Muzzer

01 Dec 2025 21:22

Replied by Muzzer on topic Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Updating from LINUXCNC - 2.8.4-23, Mint 20.3 - gmoccapy lathe structure

Category: Gmoccapy

- Masiwood123

01 Dec 2025 20:21

Replied by Masiwood123 on topic Physical buttons to 7i96s+7i77

Physical buttons to 7i96s+7i77

Category: HAL

- unknown

- unknown

01 Dec 2025 20:13

Replied by unknown on topic looking to tweak a working system for more accuracy

looking to tweak a working system for more accuracy

Category: Basic Configuration

- unknown

- unknown

01 Dec 2025 19:45

Replied by unknown on topic User name rpi-first-boot-wizard

User name rpi-first-boot-wizard

Category: Installing LinuxCNC

Time to create page: 0.334 seconds