Search Results (Searched for: )

- ihavenofish

- ihavenofish

24 Jan 2026 09:59

Replied by ihavenofish on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- Aciera

24 Jan 2026 09:35

Replied by Aciera on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- endian

24 Jan 2026 09:30

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- Hakan

- Hakan

24 Jan 2026 09:20

Replied by Hakan on topic Lichuan 4 axis stepper need help-

Lichuan 4 axis stepper need help-

Category: EtherCAT

- Aciera

24 Jan 2026 09:19

Replied by Aciera on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- rodw

24 Jan 2026 09:18

Replied by rodw on topic MAC address not retrieved (after 2 years stop)

MAC address not retrieved (after 2 years stop)

Category: Driver Boards

- ihavenofish

- ihavenofish

24 Jan 2026 09:11

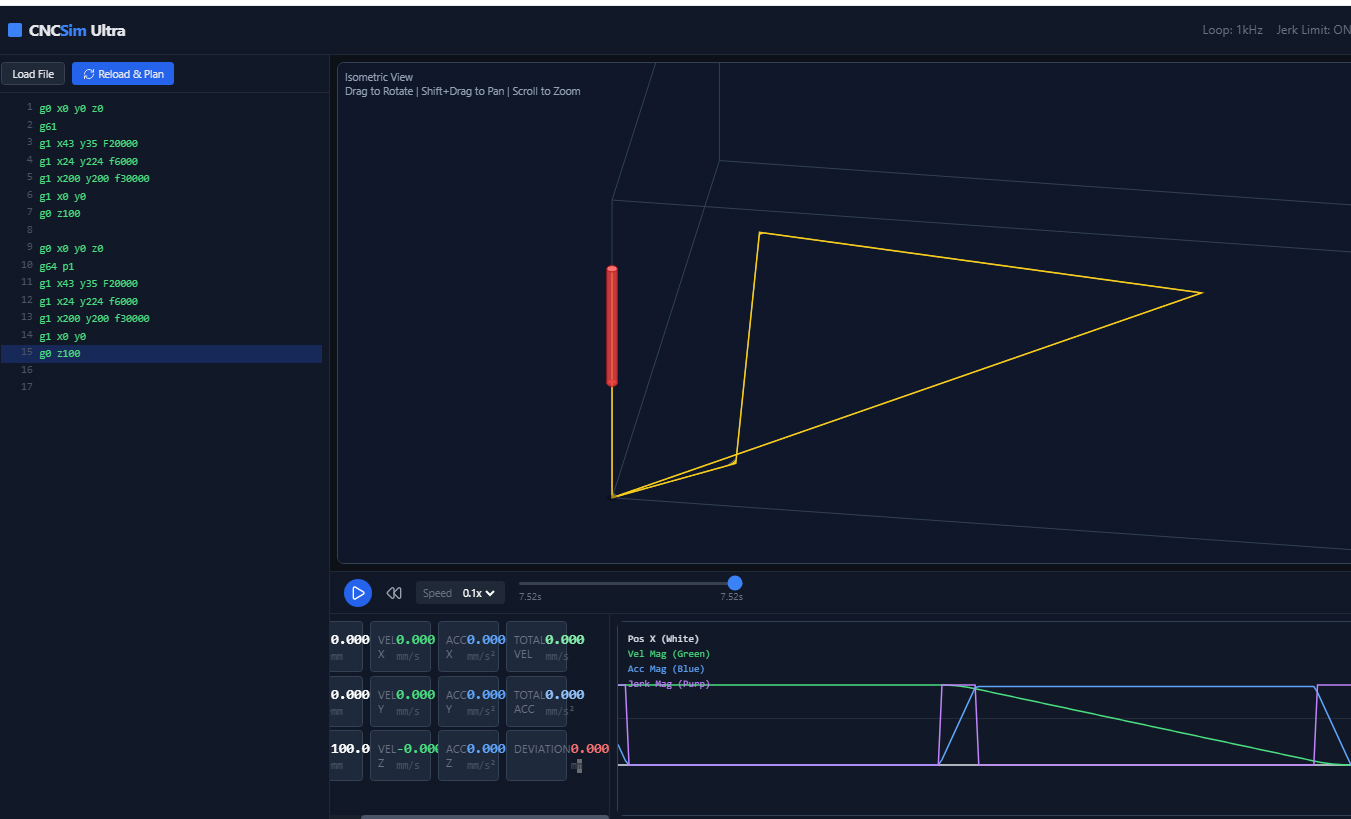

Replied by ihavenofish on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- Jocman

- Jocman

24 Jan 2026 09:03

Replied by Jocman on topic MAC address not retrieved (after 2 years stop)

MAC address not retrieved (after 2 years stop)

Category: Driver Boards

- rodw

24 Jan 2026 08:59

Replied by rodw on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- Hakan

- Hakan

24 Jan 2026 08:56

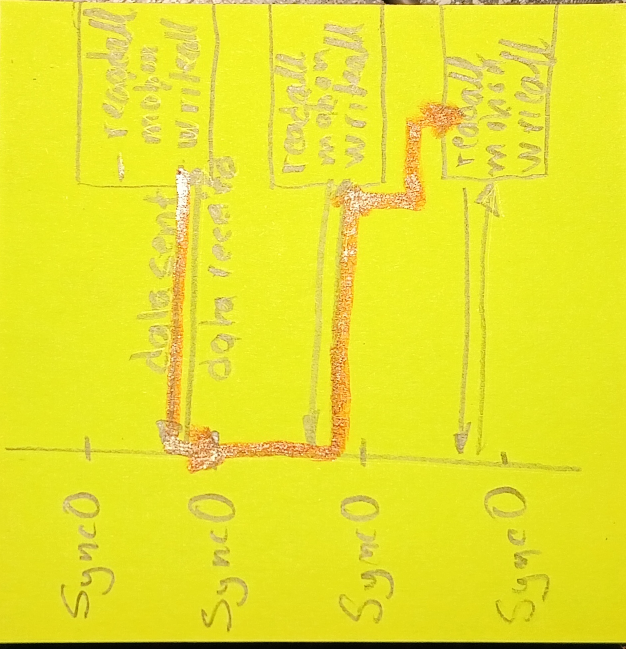

Replied by Hakan on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- ihavenofish

- ihavenofish

24 Jan 2026 08:45

Replied by ihavenofish on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- billykid

24 Jan 2026 08:43

Replied by billykid on topic 7i80db16 7i85s 7i37 firmware

7i80db16 7i85s 7i37 firmware

Category: Driver Boards

- Aciera

24 Jan 2026 08:41 - 24 Jan 2026 08:58

Replied by Aciera on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- ihavenofish

- ihavenofish

24 Jan 2026 08:32

Replied by ihavenofish on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- 3404gerber

- 3404gerber

24 Jan 2026 08:31

Replied by 3404gerber on topic Linuxcnc erste Schritte und erste Probleme, NVEM und Remora

Linuxcnc erste Schritte und erste Probleme, NVEM und Remora

Category: Deutsch

Time to create page: 0.406 seconds