Search Results (Searched for: )

- zelo

- zelo

01 Jan 2025 13:36 - 01 Jan 2025 16:20

Replied by zelo on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- _skinner

- _skinner

01 Jan 2025 13:00

Spindle speed and instatnly powered led was created by _skinner

Spindle speed and instatnly powered led

Category: Qtvcp

- Cant do this anymore bye all

01 Jan 2025 12:49

Replied by Cant do this anymore bye all on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- MrDe

- MrDe

01 Jan 2025 12:42

Replied by MrDe on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- _skinner

- _skinner

01 Jan 2025 12:34

Replied by _skinner on topic qtDragon LED Probe und Spindeldrehzahl anzeigen

qtDragon LED Probe und Spindeldrehzahl anzeigen

Category: Deutsch

- wusel0464

- wusel0464

01 Jan 2025 12:18

Replied by wusel0464 on topic Reading values from qtdragon.pref.

Reading values from qtdragon.pref.

Category: Qtvcp

- RV3Dtech

- RV3Dtech

01 Jan 2025 12:16

qtDragon LED Probe und Spindeldrehzahl anzeigen was created by RV3Dtech

qtDragon LED Probe und Spindeldrehzahl anzeigen

Category: Deutsch

- Cant do this anymore bye all

01 Jan 2025 12:10

Replied by Cant do this anymore bye all on topic 7i96s not recognized

7i96s not recognized

Category: Basic Configuration

- slowpoke

- slowpoke

01 Jan 2025 11:09

Replied by slowpoke on topic 7i96s not recognized

7i96s not recognized

Category: Basic Configuration

- BSOD

- BSOD

01 Jan 2025 10:57 - 01 Jan 2025 14:02

Replied by BSOD on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- radom

- radom

01 Jan 2025 10:17 - 01 Jan 2025 10:47

Replied by radom on topic Threading Index Varies With Speed

Threading Index Varies With Speed

Category: General LinuxCNC Questions

- TomAlborough

01 Jan 2025 06:46 - 01 Jan 2025 06:46

Replied by TomAlborough on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

- epineh

- epineh

01 Jan 2025 06:41

Replied by epineh on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- ihavenofish

- ihavenofish

01 Jan 2025 06:15

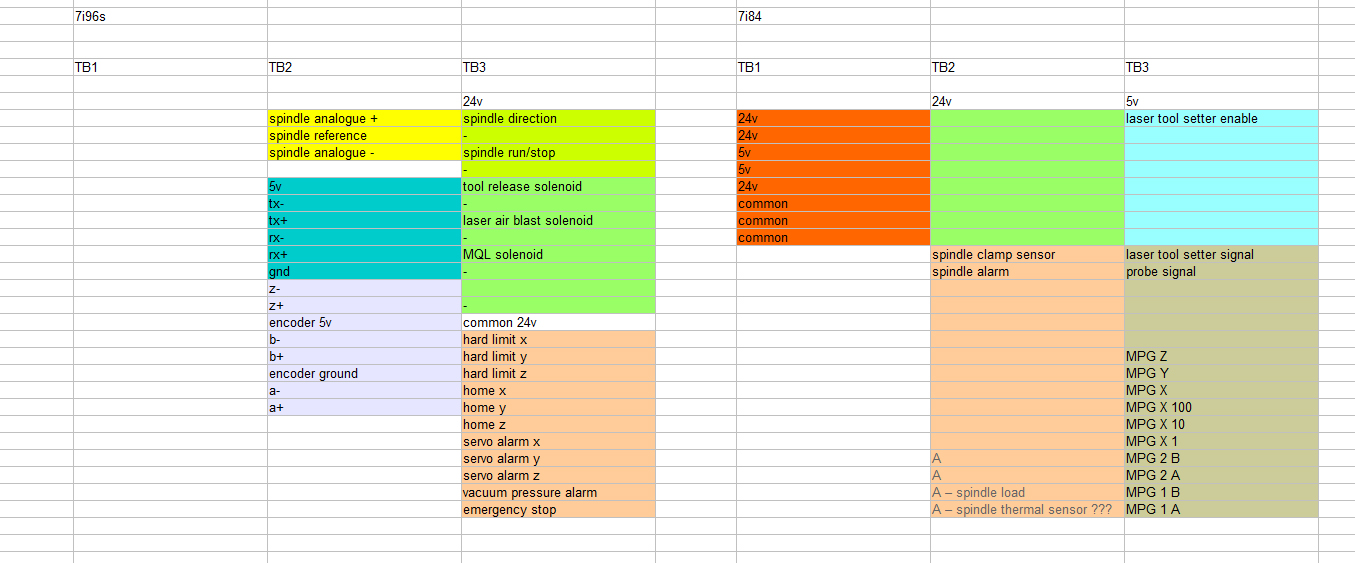

Replied by ihavenofish on topic mixing 5v and 24v on mesa cards

mixing 5v and 24v on mesa cards

Category: General LinuxCNC Questions

- Cant do this anymore bye all

01 Jan 2025 05:37 - 01 Jan 2025 05:37

Replied by Cant do this anymore bye all on topic LinuxCNC on Raspberry Pi 5

LinuxCNC on Raspberry Pi 5

Category: Installing LinuxCNC

Time to create page: 4.737 seconds