Search Results (Searched for: )

- grandixximo

22 Jan 2026 07:18 - 22 Jan 2026 07:21

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- cmorley

- cmorley

22 Jan 2026 05:12

- yrsiddhapura

- yrsiddhapura

22 Jan 2026 05:10

Replied by yrsiddhapura on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- MaHa

- MaHa

22 Jan 2026 00:10 - 22 Jan 2026 00:37

- Lcvette

22 Jan 2026 00:06

- phino

- phino

22 Jan 2026 00:05

Replied by phino on topic Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

Category: Plasma & Laser

- ncf250sd

- ncf250sd

21 Jan 2026 23:21

- Lcvette

21 Jan 2026 23:07

- ncf250sd

- ncf250sd

21 Jan 2026 22:54

- prokopcio

21 Jan 2026 22:16

Replied by prokopcio on topic Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

Category: Plasma & Laser

- grandixximo

21 Jan 2026 22:06

Replied by grandixximo on topic Ver 2.9.4 iso clean install Trouble when disabling EOE

Ver 2.9.4 iso clean install Trouble when disabling EOE

Category: EtherCAT

- prokopcio

21 Jan 2026 21:41

Replied by prokopcio on topic Laser Head Height Sensor – Looking for a Beta Tester

Laser Head Height Sensor – Looking for a Beta Tester

Category: Plasma & Laser

- grandixximo

21 Jan 2026 21:23 - 22 Jan 2026 07:26

Replied by grandixximo on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

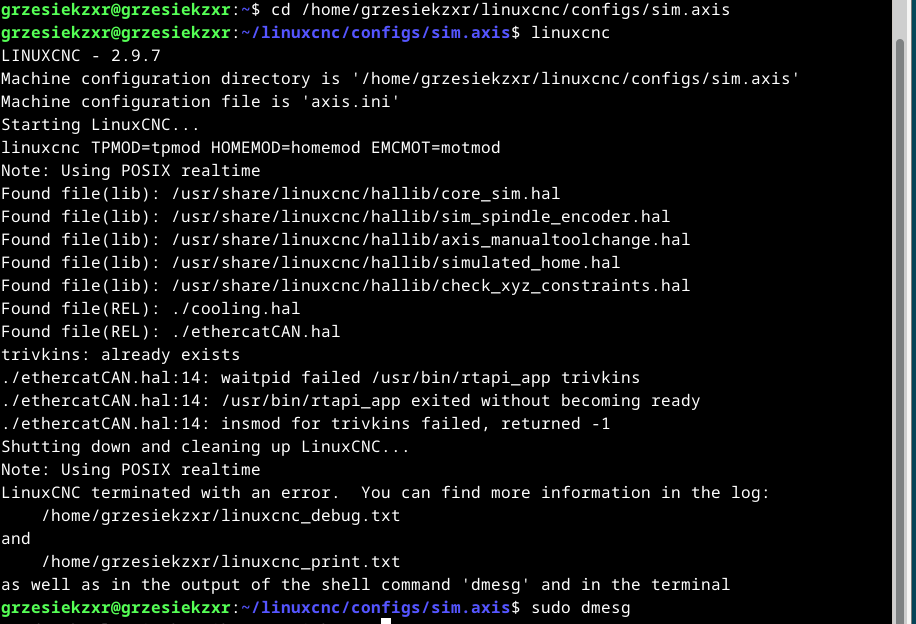

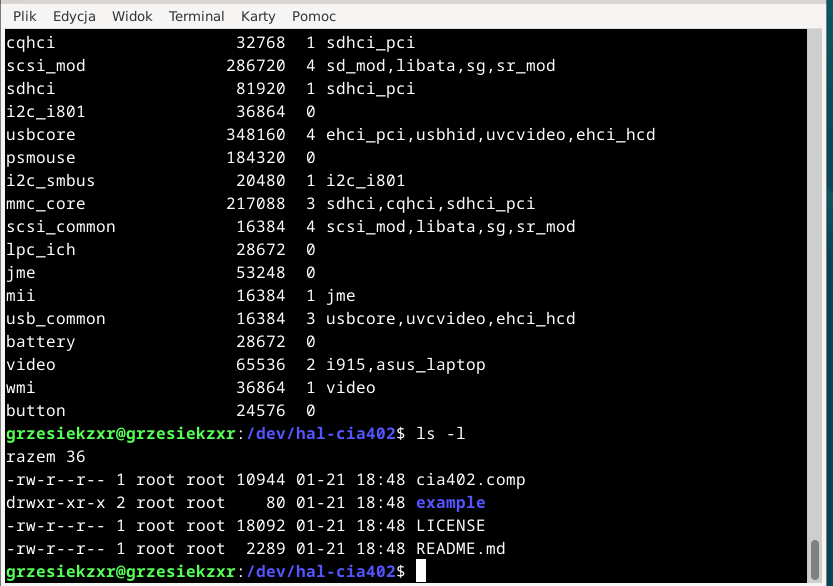

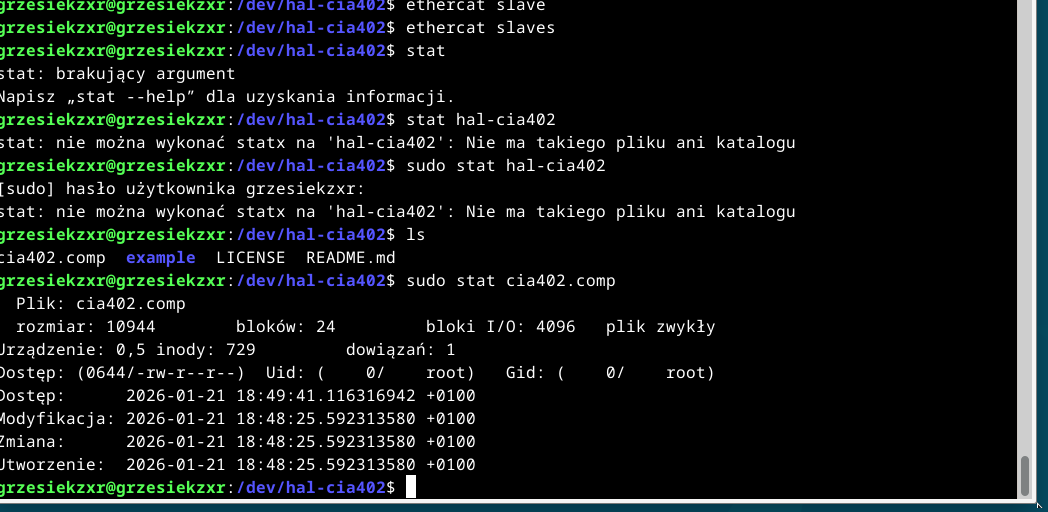

- grzester

- grzester

21 Jan 2026 20:58 - 21 Jan 2026 21:06

- cncfreak

- cncfreak

21 Jan 2026 19:21

Time to create page: 0.719 seconds