Search Results (Searched for: )

- Aciera

30 Nov 2024 09:55 - 30 Nov 2024 10:04

- Aciera

30 Nov 2024 09:48

- royka

- royka

30 Nov 2024 09:38

Replied by royka on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

- tommylight

30 Nov 2024 09:28

Replied by tommylight on topic Small touchscreen display 7-10' -> 14-16"

Small touchscreen display 7-10' -> 14-16"

Category: General LinuxCNC Questions

- tommylight

30 Nov 2024 09:22

Replied by tommylight on topic Tommylight's Dog Appreciation Thread

Tommylight's Dog Appreciation Thread

Category: Off Topic and Test Posts

- endian

30 Nov 2024 09:09

Replied by endian on topic Ethercat installation from repositories - how to step by step

Ethercat installation from repositories - how to step by step

Category: EtherCAT

- Hossein74Majidi

- Hossein74Majidi

30 Nov 2024 08:57

Replied by Hossein74Majidi on topic Real-Time Kernel with Orange Pi 4 LTS

Real-Time Kernel with Orange Pi 4 LTS

Category: General LinuxCNC Questions

- slowpoke

- slowpoke

30 Nov 2024 08:52

Replied by slowpoke on topic Small touchscreen display 7-10' -> 14-16"

Small touchscreen display 7-10' -> 14-16"

Category: General LinuxCNC Questions

- NTULINUX

30 Nov 2024 08:35

Tommylight's Dog Appreciation Thread was created by NTULINUX

Tommylight's Dog Appreciation Thread

Category: Off Topic and Test Posts

- slowpoke

- slowpoke

30 Nov 2024 08:33

- abdulasis12

- abdulasis12

30 Nov 2024 08:16

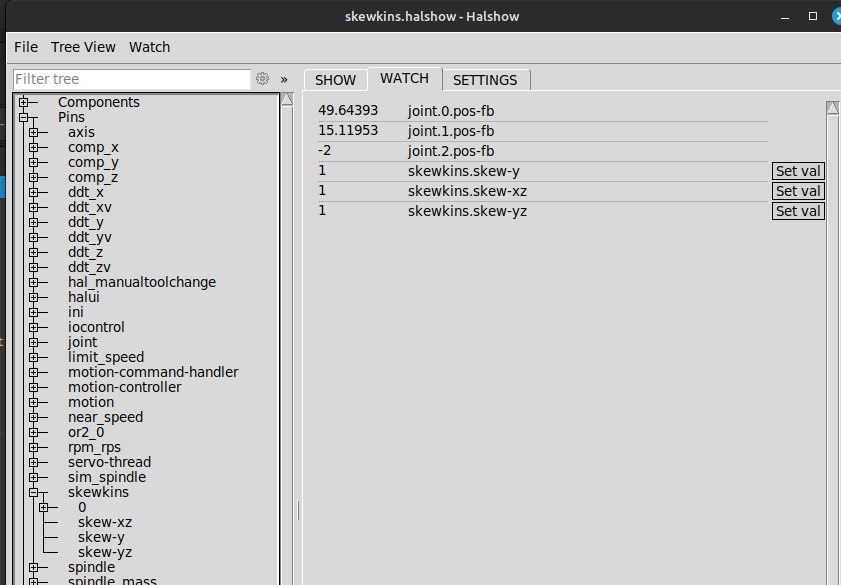

Replied by abdulasis12 on topic Skew correction/perpendicularity correction (millkins or millkins_xyz)

Skew correction/perpendicularity correction (millkins or millkins_xyz)

Category: Basic Configuration

- tommylight

30 Nov 2024 08:11

Replied by tommylight on topic Tip on how to plan a machine

Tip on how to plan a machine

Category: General LinuxCNC Questions

- timo

- timo

30 Nov 2024 08:05

Replied by timo on topic Tip on how to plan a machine

Tip on how to plan a machine

Category: General LinuxCNC Questions

- gitin

- gitin

30 Nov 2024 07:59

Replied by gitin on topic Help: How to run X and A axis with different feed rates simultaneously?

Help: How to run X and A axis with different feed rates simultaneously?

Category: G&M Codes

- tommylight

30 Nov 2024 07:51

Replied by tommylight on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

Time to create page: 0.567 seconds