Search Results (Searched for: )

- anfänger

05 Aug 2024 16:31

Replied by anfänger on topic probe basic dro scales in inces instead mm

probe basic dro scales in inces instead mm

Category: QtPyVCP

- meister

- meister

05 Aug 2024 16:09

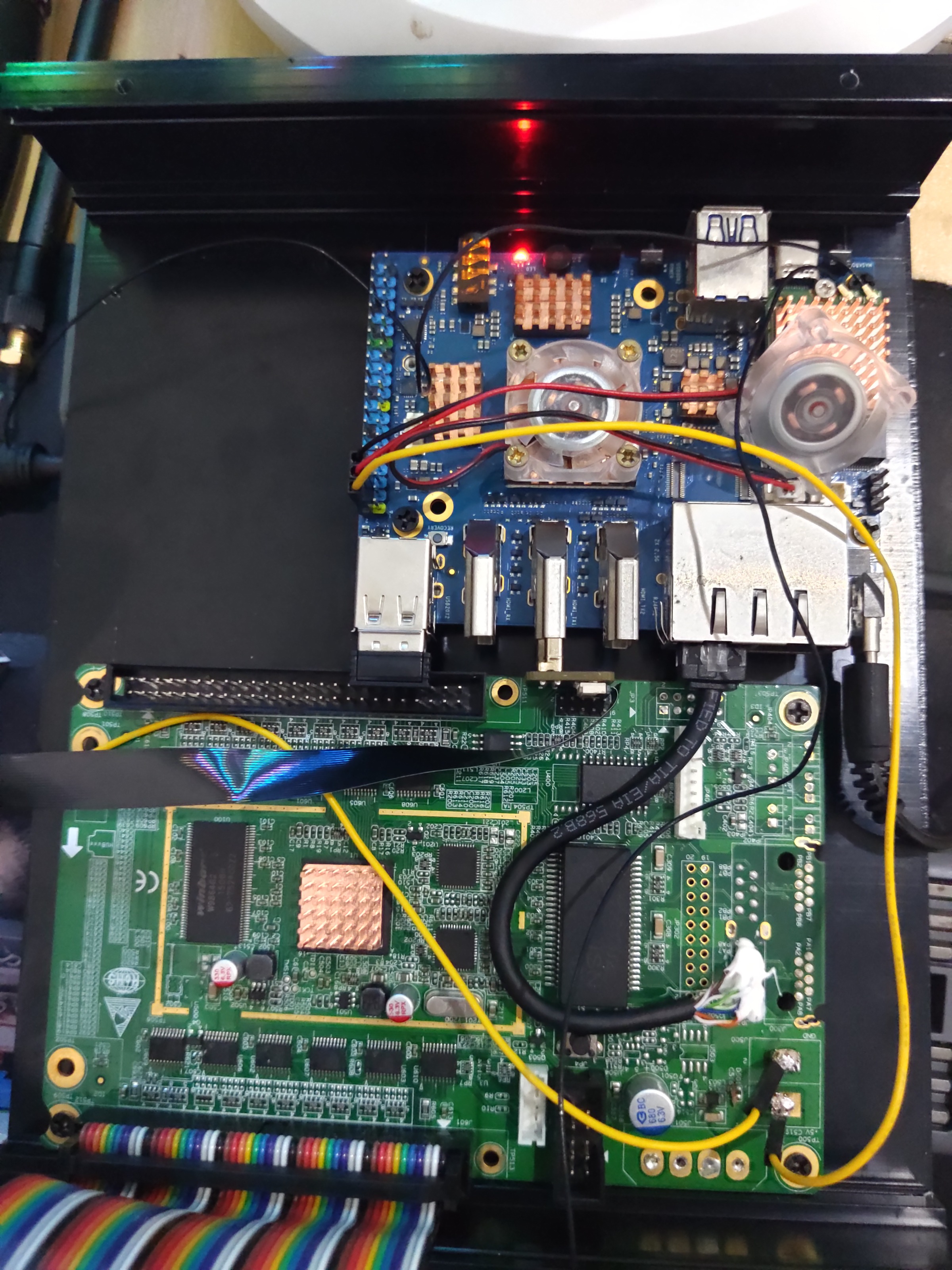

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- AndyDM01

- AndyDM01

05 Aug 2024 16:07 - 05 Aug 2024 16:22

transfer the deb files i created to the other system was created by AndyDM01

transfer the deb files i created to the other system

Category: EtherCAT

- sin-do-re

- sin-do-re

05 Aug 2024 15:32

Replied by sin-do-re on topic Scaling power based on % of imposed velocity

Scaling power based on % of imposed velocity

Category: General LinuxCNC Questions

- hectormhr

- hectormhr

05 Aug 2024 15:15

Replied by hectormhr on topic Experience with Moons Industries Ethercat Servo

Experience with Moons Industries Ethercat Servo

Category: EtherCAT

- scottlaird

05 Aug 2024 15:11

Replied by scottlaird on topic New LinuxCNC-Ethercat git tree

New LinuxCNC-Ethercat git tree

Category: EtherCAT

- Bennett

05 Aug 2024 14:45

- PCW

05 Aug 2024 14:35 - 05 Aug 2024 14:36

Replied by PCW on topic Scaling power based on % of imposed velocity

Scaling power based on % of imposed velocity

Category: General LinuxCNC Questions

- PCW

05 Aug 2024 14:28

- Muftijaja

- Muftijaja

05 Aug 2024 14:20

Replied by Muftijaja on topic Latency Test OK, dennoch Fehlermeldung

Latency Test OK, dennoch Fehlermeldung

Category: Deutsch

- sin-do-re

- sin-do-re

05 Aug 2024 14:17 - 05 Aug 2024 14:21

Replied by sin-do-re on topic Scaling power based on % of imposed velocity

Scaling power based on % of imposed velocity

Category: General LinuxCNC Questions

- onceloved

05 Aug 2024 14:09 - 05 Aug 2024 14:13

Replied by onceloved on topic EtherCAT i/o board for spindle, estop and mpg

EtherCAT i/o board for spindle, estop and mpg

Category: EtherCAT

- Muftijaja

- Muftijaja

05 Aug 2024 14:02

Replied by Muftijaja on topic Latency Test OK, dennoch Fehlermeldung

Latency Test OK, dennoch Fehlermeldung

Category: Deutsch

- tommylight

05 Aug 2024 13:57

Replied by tommylight on topic Latency Test OK, dennoch Fehlermeldung

Latency Test OK, dennoch Fehlermeldung

Category: Deutsch

- Muftijaja

- Muftijaja

05 Aug 2024 13:38

Replied by Muftijaja on topic Latency Test OK, dennoch Fehlermeldung

Latency Test OK, dennoch Fehlermeldung

Category: Deutsch

Time to create page: 0.794 seconds