Search Results (Searched for: )

- bkt

09 Sep 2024 18:49

- bkt

09 Sep 2024 18:45 - 09 Sep 2024 18:52

- machinedude

09 Sep 2024 18:28

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- spumco

- spumco

09 Sep 2024 18:21

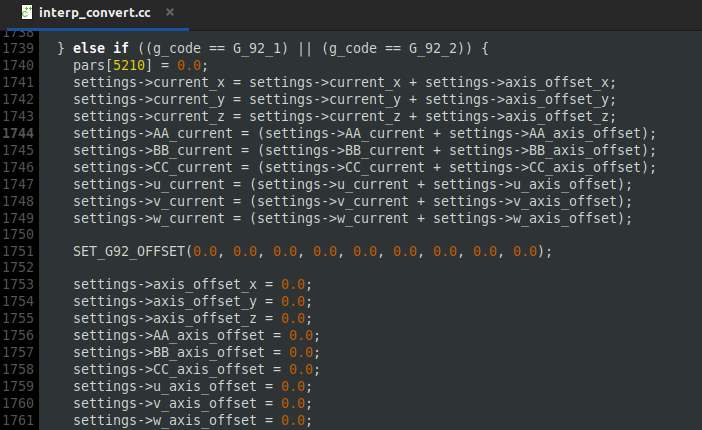

Replied by spumco on topic Probe Basic subroutine parameter - #5210?

Probe Basic subroutine parameter - #5210?

Category: QtPyVCP

- RDA

- RDA

09 Sep 2024 18:19

- Carsten

- Carsten

09 Sep 2024 18:05

- bertoldo

- bertoldo

09 Sep 2024 17:52

Replied by bertoldo on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- Todd Zuercher

09 Sep 2024 17:52

- snowgoer540

09 Sep 2024 17:26 - 09 Sep 2024 17:29

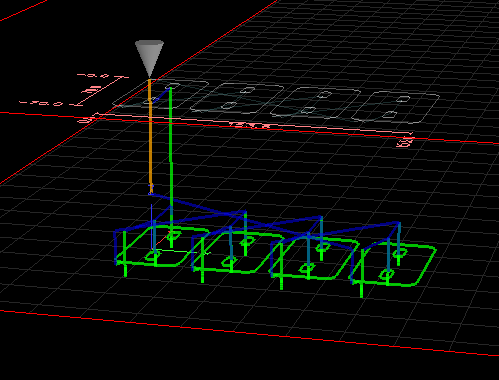

Replied by snowgoer540 on topic Showstopper Plasma Cutter retrofit

Showstopper Plasma Cutter retrofit

Category: Show Your Stuff

- jjdege

09 Sep 2024 17:22

Replied by jjdege on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- bertoldo

- bertoldo

09 Sep 2024 17:08

Replied by bertoldo on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- bertoldo

- bertoldo

09 Sep 2024 17:03

Replied by bertoldo on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- jjdege

09 Sep 2024 16:52

Replied by jjdege on topic Notes from installation of ethercat on Raspberry Pi 4

Notes from installation of ethercat on Raspberry Pi 4

Category: EtherCAT

- Aciera

09 Sep 2024 16:27 - 09 Sep 2024 16:58

Replied by Aciera on topic Probe Basic subroutine parameter - #5210?

Probe Basic subroutine parameter - #5210?

Category: QtPyVCP

- spumco

- spumco

09 Sep 2024 16:16

Replied by spumco on topic Probe Basic subroutine parameter - #5210?

Probe Basic subroutine parameter - #5210?

Category: QtPyVCP

Time to create page: 0.607 seconds