Search Results (Searched for: )

- snowgoer540

07 Mar 2025 03:18

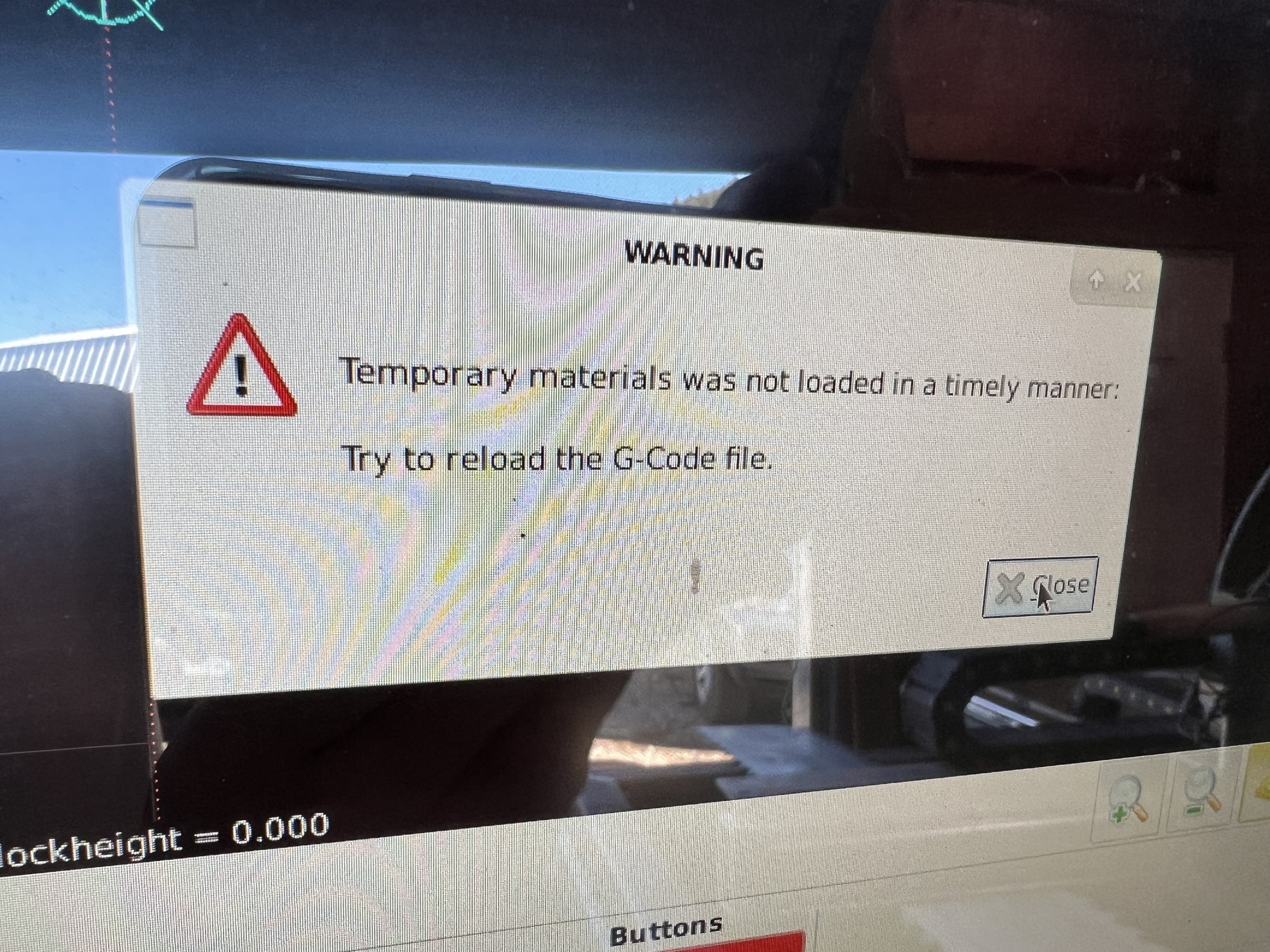

Replied by snowgoer540 on topic Temporary materials was not loaded in a timely manner

Temporary materials was not loaded in a timely manner

Category: Plasmac

- cmorley

- cmorley

07 Mar 2025 03:02

Replied by cmorley on topic Qtvcp Development Discussions

Qtvcp Development Discussions

Category: Qtvcp

- Nathan40

- Nathan40

07 Mar 2025 02:57

Replied by Nathan40 on topic Ethernet Settings for Raspi4

Ethernet Settings for Raspi4

Category: Installing LinuxCNC

- rodw

07 Mar 2025 02:56

Replied by rodw on topic New ethercat / probe basic control for minimonster

New ethercat / probe basic control for minimonster

Category: CNC Machines

- Sziggy_NC

- Sziggy_NC

07 Mar 2025 02:55

Replied by Sziggy_NC on topic Calling pockets with carousel

Calling pockets with carousel

Category: Basic Configuration

- ihavenofish

- ihavenofish

07 Mar 2025 02:47

Replied by ihavenofish on topic Problems with Lichuan Ethercat servo drive

Problems with Lichuan Ethercat servo drive

Category: EtherCAT

- ihavenofish

- ihavenofish

07 Mar 2025 02:43

Replied by ihavenofish on topic New ethercat / probe basic control for minimonster

New ethercat / probe basic control for minimonster

Category: CNC Machines

- cmorley

- cmorley

07 Mar 2025 02:38

- Philip Lydin

- Philip Lydin

07 Mar 2025 01:44

- Chia

- Chia

07 Mar 2025 01:41

Replied by Chia on topic LinuxCNC coreXY homing question

LinuxCNC coreXY homing question

Category: General LinuxCNC Questions

- Philip Lydin

- Philip Lydin

07 Mar 2025 01:40 - 07 Mar 2025 01:41

Replied by Philip Lydin on topic Problems with Lichuan Ethercat servo drive

Problems with Lichuan Ethercat servo drive

Category: EtherCAT

- FraesPaul

- FraesPaul

07 Mar 2025 00:59 - 07 Mar 2025 00:59

Replied by FraesPaul on topic Installation 2.9.4 Debian Bookworm Preempt-RT ISO // Probleme

Installation 2.9.4 Debian Bookworm Preempt-RT ISO // Probleme

Category: Deutsch

- PCW

06 Mar 2025 23:47 - 06 Mar 2025 23:48

Time to create page: 0.946 seconds