Search Results (Searched for: )

- cnbbom

- cnbbom

09 Jan 2026 19:21 - 10 Jan 2026 22:42

Replied by cnbbom on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- Muzzer

- Muzzer

09 Jan 2026 19:03

- NWE

09 Jan 2026 18:59

- andypugh

09 Jan 2026 18:01

Replied by andypugh on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- cnbbom

- cnbbom

09 Jan 2026 17:45

Replied by cnbbom on topic New and Working RTAI debs for 2.9

New and Working RTAI debs for 2.9

Category: Installing LinuxCNC

- tommylight

09 Jan 2026 17:11

Replied by tommylight on topic Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Category: Driver Boards

- sataran

- sataran

09 Jan 2026 16:52

Replied by sataran on topic Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Category: Driver Boards

- PCW

09 Jan 2026 16:40

Replied by PCW on topic 7i92M + 7i76 add PWM+PktUART

7i92M + 7i76 add PWM+PktUART

Category: Driver Boards

- amanker

- amanker

09 Jan 2026 16:11

Replied by amanker on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- Murphy

- Murphy

09 Jan 2026 16:02

Replied by Murphy on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- PCW

09 Jan 2026 15:54 - 09 Jan 2026 15:54

Replied by PCW on topic Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Bitfile or help – Mesa 6i25 + 7i74 (BiSS-C) + 8i20 + 7i70/7i87

Category: Driver Boards

- lorenzing

- lorenzing

09 Jan 2026 13:39

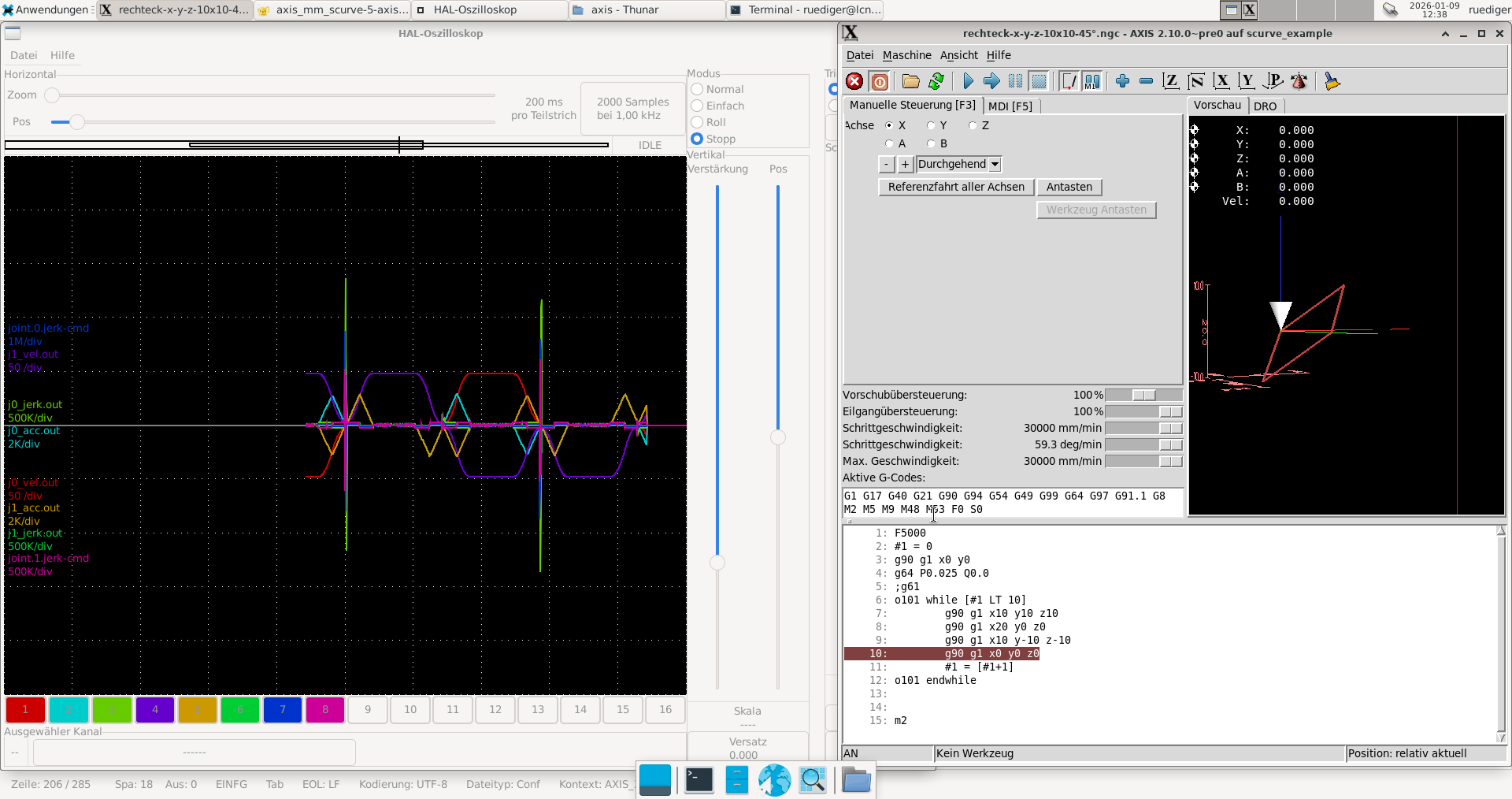

- ruediger123

- ruediger123

09 Jan 2026 11:55 - 09 Jan 2026 11:57

Replied by ruediger123 on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- lorenzing

- lorenzing

09 Jan 2026 10:02 - 09 Jan 2026 10:49

- lorenzing

- lorenzing

09 Jan 2026 09:03 - 09 Jan 2026 09:11

Time to create page: 0.396 seconds