Search Results (Searched for: )

- tommylight

31 Dec 2025 13:29

Replied by tommylight on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Category: Plasmac

- xenon-alien

31 Dec 2025 12:43 - 31 Dec 2025 12:50

Replied by xenon-alien on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

[ Vfdmod ] An easy VFD control over MODBUS RTU

Category: HAL

- Hakan

- Hakan

31 Dec 2025 10:56

Replied by Hakan on topic refClockSyncCycles="-1", I got Messages.

refClockSyncCycles="-1", I got Messages.

Category: EtherCAT

- workshop54

- workshop54

31 Dec 2025 10:39

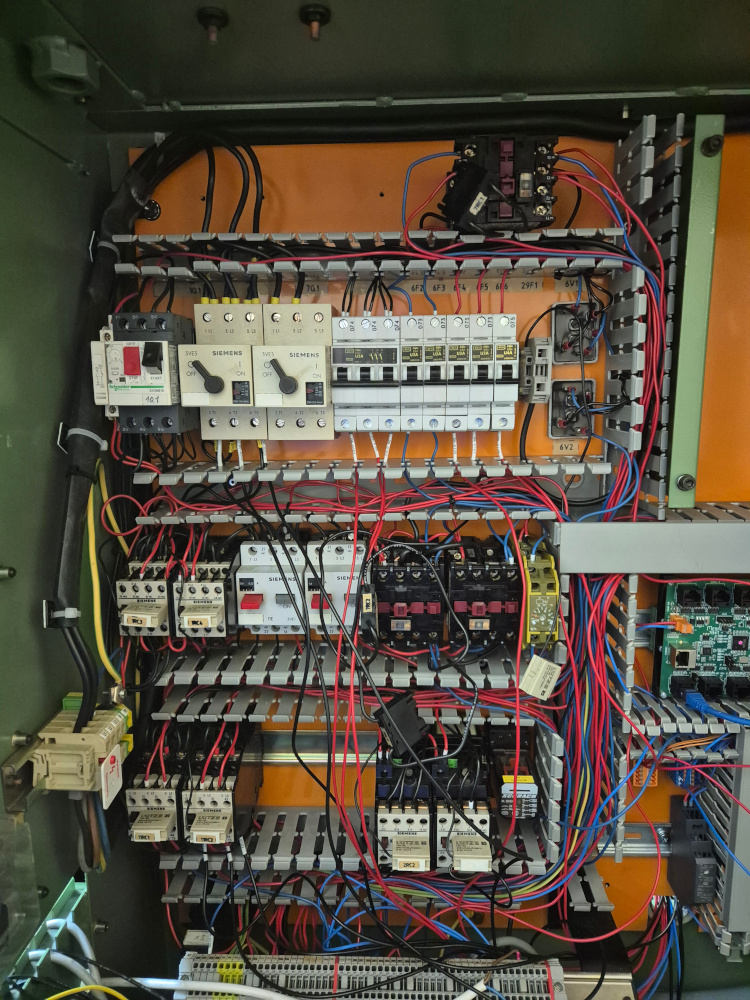

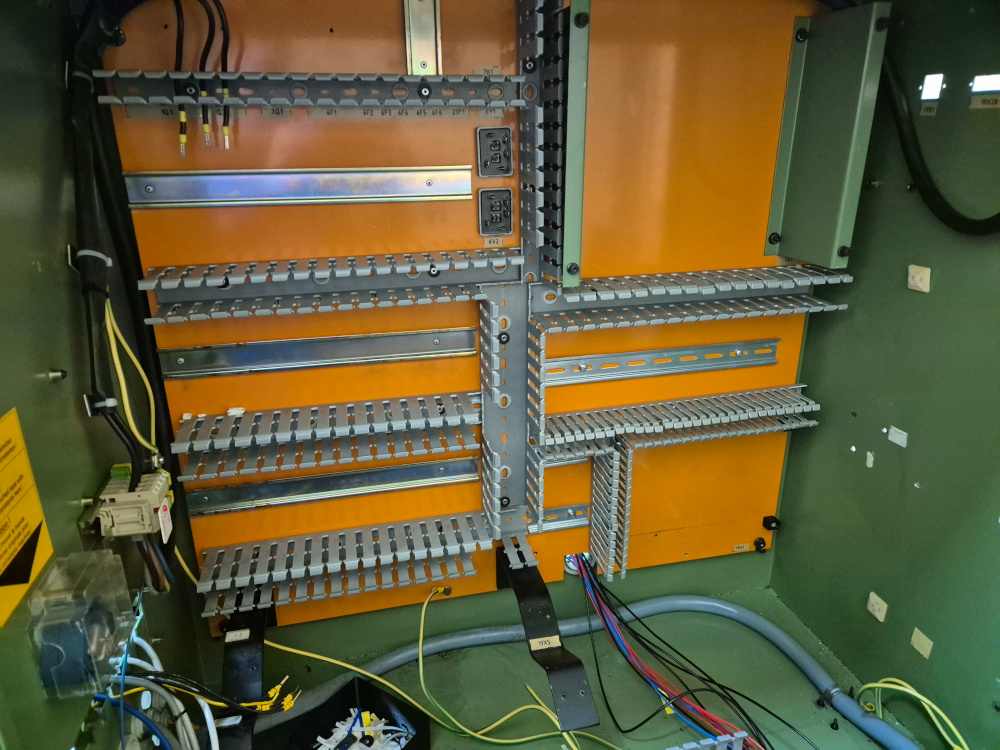

Replied by workshop54 on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

Category: Milling Machines

- tar_san

- tar_san

31 Dec 2025 09:47

Replied by tar_san on topic refClockSyncCycles="-1", I got Messages.

refClockSyncCycles="-1", I got Messages.

Category: EtherCAT

- endian

31 Dec 2025 08:39

Replied by endian on topic LinuxCNC S-Curve Accelerations

LinuxCNC S-Curve Accelerations

Category: General LinuxCNC Questions

- endian

31 Dec 2025 08:32

- Ozcnc

- Ozcnc

31 Dec 2025 08:29

- grandixximo

31 Dec 2025 07:44 - 31 Dec 2025 07:45

Replied by grandixximo on topic Ethercat random jitter fix

Ethercat random jitter fix

Category: EtherCAT

- Bendandsend

- Bendandsend

31 Dec 2025 04:32 - 31 Dec 2025 23:14

MESA 1I76EU Firmware was created by Bendandsend

MESA 1I76EU Firmware

Category: General LinuxCNC Questions

- Bendandsend

- Bendandsend

31 Dec 2025 03:26

- snowgoer540

30 Dec 2025 23:57

Replied by snowgoer540 on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Category: Plasmac

- nwallace

- nwallace

30 Dec 2025 23:32

Replied by nwallace on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

[ Vfdmod ] An easy VFD control over MODBUS RTU

Category: HAL

- xenon-alien

30 Dec 2025 23:20

Replied by xenon-alien on topic [ Vfdmod ] An easy VFD control over MODBUS RTU

[ Vfdmod ] An easy VFD control over MODBUS RTU

Category: HAL

- NWE

- NWE

30 Dec 2025 23:20 - 30 Dec 2025 23:34

Time to create page: 0.491 seconds