LinuxCNC Features - a kind of NGCGUI

- Nick

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 125

- Thank you received: 11

31 Jul 2015 14:27 #61063

by Nick

Replied by Nick on topic LinuxCNC Features - a kind of NGCGUI

To my mind we should choose from two option.

1. turn on/of the spindle before and after each cutting feature (we can call O<spindle-start> and O<spindle-stop> there we can also turn on the flood and etc)

2. turn on/of by the task...

To my mind the first option is better.

But we will have to put it in each every feature once again.

By "we" I mean developpers, I thin it's no need for the user to make able to make this choise.

1. turn on/of the spindle before and after each cutting feature (we can call O<spindle-start> and O<spindle-stop> there we can also turn on the flood and etc)

2. turn on/of by the task...

To my mind the first option is better.

But we will have to put it in each every feature once again.

By "we" I mean developpers, I thin it's no need for the user to make able to make this choise.

Please Log in or Create an account to join the conversation.

- FernV

-

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

01 Aug 2015 12:30 #61090

by FernV

Replied by FernV on topic LinuxCNC Features - a kind of NGCGUI

Hi Nick,

I do not think option 1 would work with my VFD. I remember when setting it up it would raise an exception when trying to start while the motor was still spinning. Would it still fail now ? I can not test before a few weeks because we are re-locating and there are other higher level priorities.

I still think M3/M4 should be called right after a tool change but if you want to make simple tests, use custom gcode where you think it needs to be called. Is it a good idea to have this kind of code :

M3 M8

..do cut 1

M5 M9

M3 M8

.. do cut 2

M5 M9

M2

I re-checked M2 and it calls M5 and M9 so there is no need to change the end of to_gcode().

To move the spindle away from the workpiece when completed, I think I will add an optionnal post-amble.ngc file that can be edited as needed by the user just like defaults.ngc or I can create a new feature that can be added as the last one to do this or I can refine task.ini so users would be reminded to do it or I can do all of those

Regards,

Fern

I do not think option 1 would work with my VFD. I remember when setting it up it would raise an exception when trying to start while the motor was still spinning. Would it still fail now ? I can not test before a few weeks because we are re-locating and there are other higher level priorities.

I still think M3/M4 should be called right after a tool change but if you want to make simple tests, use custom gcode where you think it needs to be called. Is it a good idea to have this kind of code :

M3 M8

..do cut 1

M5 M9

M3 M8

.. do cut 2

M5 M9

M2

I re-checked M2 and it calls M5 and M9 so there is no need to change the end of to_gcode().

To move the spindle away from the workpiece when completed, I think I will add an optionnal post-amble.ngc file that can be edited as needed by the user just like defaults.ngc or I can create a new feature that can be added as the last one to do this or I can refine task.ini so users would be reminded to do it or I can do all of those

Regards,

Fern

Please Log in or Create an account to join the conversation.

- fixer

- Offline

- Premium Member

-

Less

More

- Posts: 132

- Thank you received: 27

04 Sep 2015 21:02 #62122

by fixer

Replied by fixer on topic LinuxCNC Features - a kind of NGCGUI

hi guys,

I've been using features almost a year now, and i love it. Great work you have done here! It is developing really well.

I just wanna inform you about a few bugs i found in latest version:

- Spindle is always set to 1000 rpm, no matter what i type in tool change - altought the final spindle velo is ok, it changes speed when cutting last cut.

- feature "slot" doesnt work ok - the dimensions of the cut are not the same as dimensions entered for height and width - I suppose there is something wrong with tool radius compensation calculation

- cutting from positive Z to Z>=0.000 doesnt work - it says invalid cutt depth.For example if you set your Z zero on the bottom of workpiece and you dont want to cut trough it.

And leave spindle as it is, turn on with the first move approaching start point, turn off at rapid Z at the end of program. On a big machine like mine it takes several seconds to get the spindle to speed, so constant turning on and off is not OK.

I've been using features almost a year now, and i love it. Great work you have done here! It is developing really well.

I just wanna inform you about a few bugs i found in latest version:

- Spindle is always set to 1000 rpm, no matter what i type in tool change - altought the final spindle velo is ok, it changes speed when cutting last cut.

- feature "slot" doesnt work ok - the dimensions of the cut are not the same as dimensions entered for height and width - I suppose there is something wrong with tool radius compensation calculation

- cutting from positive Z to Z>=0.000 doesnt work - it says invalid cutt depth.For example if you set your Z zero on the bottom of workpiece and you dont want to cut trough it.

And leave spindle as it is, turn on with the first move approaching start point, turn off at rapid Z at the end of program. On a big machine like mine it takes several seconds to get the spindle to speed, so constant turning on and off is not OK.

Please Log in or Create an account to join the conversation.

- FernV

-

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

05 Sep 2015 21:41 - 05 Sep 2015 21:47 #62149

by FernV

Replied by FernV on topic LinuxCNC Features - a kind of NGCGUI

Hi,

Thank you very much for your very important comments, this is really needed for improving. I would really like more.

It's an unfortunate oversight.

In fv_tool-change.ini add this new line after "F#param_feed"

#<_spindle_rpm> = #param_speed

Tool radius compensation is calculated by LinuxCNC, so I guess this is OK.

The width is the diameter of the arc and the length is the distance between center of arcs.

As for now I can not use my milling to test. I will follow up when I can.

By the way, is the diameter in your tool table for the mill you use the right one ?

I changed it for the new release to come but if you need it NOW here is what to do.

The files that need to be edited are in lib directory : fv_circle.ngc, fv_ellipse.ngc, fv_polygon.ngc, fv_rectangle.ngc, fv_slot-arc.ngc, fv_slot.ngc

Find the block that says : if [#<cut_depth> EQ 0.0]

Replace it with : if [#<cut_depth> GE #<cut_start>]

Delete the else condition and the following line keeping the the last line of the block, the one that says "endif"

You will then be able to use any number as long as "cut depth" is lower than "cut start"

I agree

I will have a new release in a few weeks with many improvements to make it much easier to use.

There are changes in the subroutines and a few new one to come.

If there is something specific you would like to see added, tell me about it

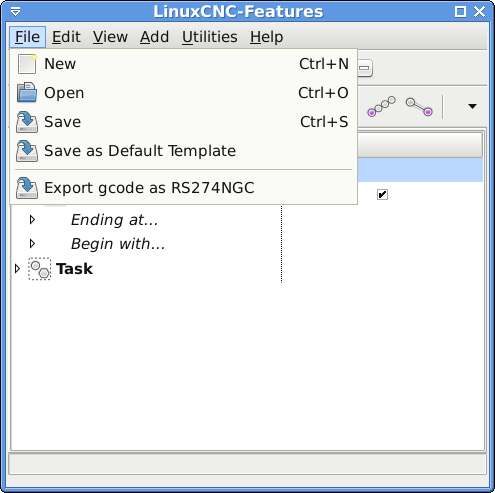

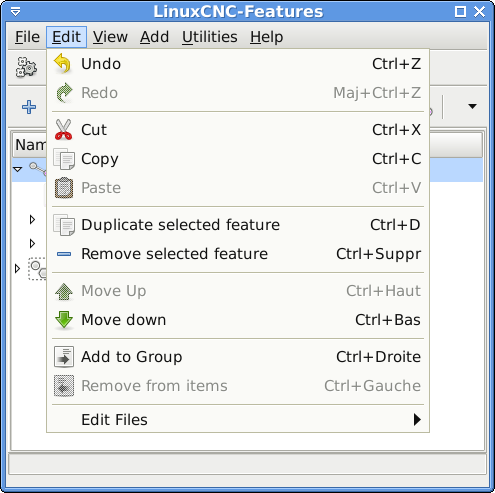

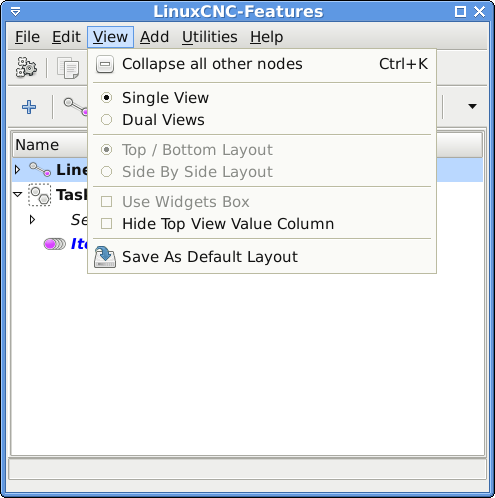

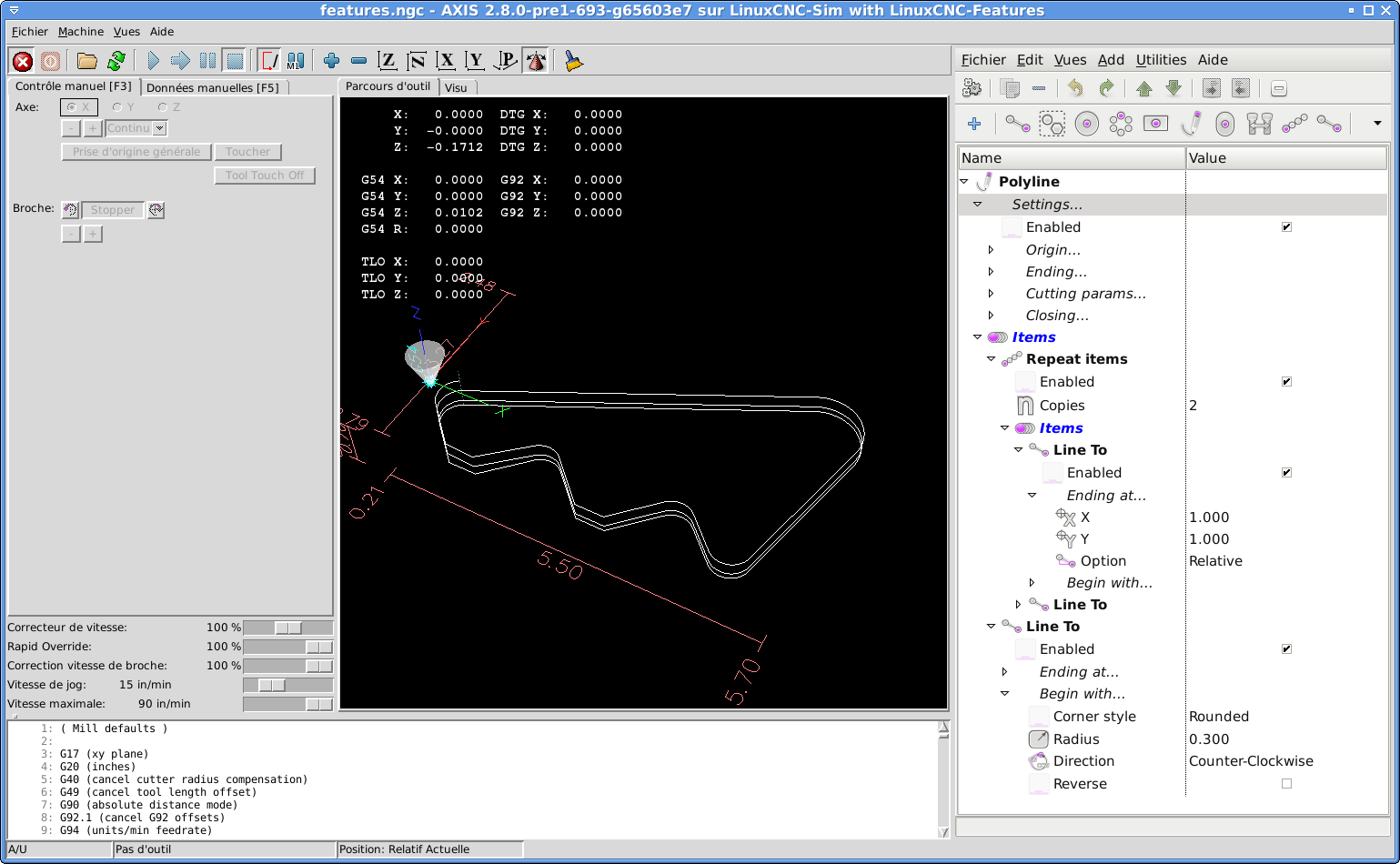

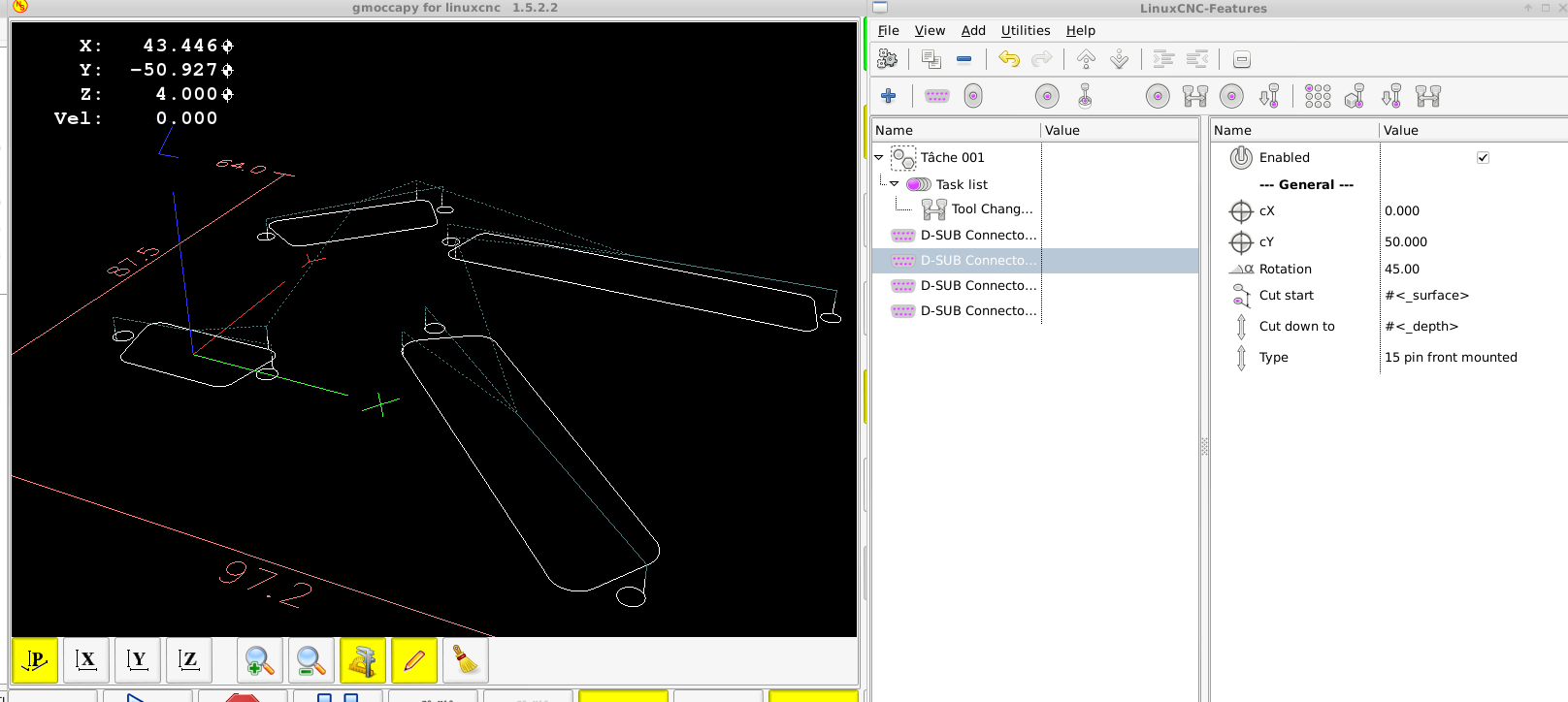

A few screen shot of things to come. Please comment

Menu is reorganized and include many accelerators/shortcuts

Better grouping makes it easier to use. Single view is default now

Best regards

Fern

Thank you very much for your very important comments, this is really needed for improving. I would really like more.

hi guys,

I've been using features almost a year now, and i love it. Great work you have done here! It is developing really well.

I just wanna inform you about a few bugs i found in latest version:

- Spindle is always set to 1000 rpm, no matter what i type in tool change - altought the final spindle velo is ok, it changes speed when cutting last cut.

It's an unfortunate oversight.

In fv_tool-change.ini add this new line after "F#param_feed"

#<_spindle_rpm> = #param_speed

- feature "slot" doesnt work ok - the dimensions of the cut are not the same as dimensions entered for height and width - I suppose there is something wrong with tool radius compensation calculation

Tool radius compensation is calculated by LinuxCNC, so I guess this is OK.

The width is the diameter of the arc and the length is the distance between center of arcs.

As for now I can not use my milling to test. I will follow up when I can.

By the way, is the diameter in your tool table for the mill you use the right one ?

- cutting from positive Z to Z>=0.000 doesnt work - it says invalid cutt depth.For example if you set your Z zero on the bottom of workpiece and you dont want to cut trough it.

I changed it for the new release to come but if you need it NOW here is what to do.

The files that need to be edited are in lib directory : fv_circle.ngc, fv_ellipse.ngc, fv_polygon.ngc, fv_rectangle.ngc, fv_slot-arc.ngc, fv_slot.ngc

Find the block that says : if [#<cut_depth> EQ 0.0]

Replace it with : if [#<cut_depth> GE #<cut_start>]

Delete the else condition and the following line keeping the the last line of the block, the one that says "endif"

You will then be able to use any number as long as "cut depth" is lower than "cut start"

And leave spindle as it is, turn on with the first move approaching start point, turn off at rapid Z at the end of program. On a big machine like mine it takes several seconds to get the spindle to speed, so constant turning on and off is not OK.

I agree

I will have a new release in a few weeks with many improvements to make it much easier to use.

There are changes in the subroutines and a few new one to come.

If there is something specific you would like to see added, tell me about it

A few screen shot of things to come. Please comment

Menu is reorganized and include many accelerators/shortcuts

Better grouping makes it easier to use. Single view is default now

Best regards

Fern

Last edit: 05 Sep 2015 21:47 by FernV.

Please Log in or Create an account to join the conversation.

- fixer

- Offline

- Premium Member

-

Less

More

- Posts: 132

- Thank you received: 27

06 Sep 2015 01:01 - 06 Sep 2015 01:07 #62150

by fixer

Replied by fixer on topic LinuxCNC Features - a kind of NGCGUI

ok, thanks for the updates,

regarding slots, i am not sure but i belive that the problem was that, as you say, the length is between centers, and i was wrongly expecting value between arcs...

I am working on a subrutine for features for cutting out shapes for common d-sub connectors in enclosures. Not what every machinist would need, but there are quite a lot of electro guys with CNCs, I am sure someone will find it useful. I will post it here tomorow, if everything goes OK.

I would also like to propose a small change in GUI: Can you make the Add feature window to not be additional window, but would show the menu in the "value" part of the main window? After you would choose feature to add it would disapear and normaly show values as before. I am using touchscreen and it is not convenient to have additional windows on top of main.

And with touchscreen, taping on a feature or folder doesnt open it, it only selects and i have to press enter to open/add it. Can you do an option for adding a feature with single/double click? User with mouse will propably want double click.

A small popup numerical keyboard wich would show when selecting a value is propably too much to ask, a?

I am learning python, but curently i am not good enought to make that kind of changes in your program...

and you can hide the shortcuts for features, as i personaly never use them, and make upper icons bigger, again because of touchscreen being inacurrate...

regarding slots, i am not sure but i belive that the problem was that, as you say, the length is between centers, and i was wrongly expecting value between arcs...

I am working on a subrutine for features for cutting out shapes for common d-sub connectors in enclosures. Not what every machinist would need, but there are quite a lot of electro guys with CNCs, I am sure someone will find it useful. I will post it here tomorow, if everything goes OK.

I would also like to propose a small change in GUI: Can you make the Add feature window to not be additional window, but would show the menu in the "value" part of the main window? After you would choose feature to add it would disapear and normaly show values as before. I am using touchscreen and it is not convenient to have additional windows on top of main.

And with touchscreen, taping on a feature or folder doesnt open it, it only selects and i have to press enter to open/add it. Can you do an option for adding a feature with single/double click? User with mouse will propably want double click.

A small popup numerical keyboard wich would show when selecting a value is propably too much to ask, a?

I am learning python, but curently i am not good enought to make that kind of changes in your program...

and you can hide the shortcuts for features, as i personaly never use them, and make upper icons bigger, again because of touchscreen being inacurrate...

Last edit: 06 Sep 2015 01:07 by fixer. Reason: add request

Please Log in or Create an account to join the conversation.

- fixer

- Offline

- Premium Member

-

Less

More

- Posts: 132

- Thank you received: 27

06 Sep 2015 16:09 #62161

by fixer

Replied by fixer on topic LinuxCNC Features - a kind of NGCGUI

As promised, subroutines for D-SUB cutouts. Dimensions for connectors are hardcoded in metric, use tool no larger than 3mm. For imperial units, just recalculate hardcoded dimensions in lines after 17 in ngc, or change into metric before subroutine call with custom G-code.

You can include them in final, but i see no point in this because very few people will find it useful. We could make repository or a new topic for collecting diferent subroutines, what do other users think?

You can include them in final, but i see no point in this because very few people will find it useful. We could make repository or a new topic for collecting diferent subroutines, what do other users think?

Please Log in or Create an account to join the conversation.

- johns

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

06 Sep 2015 20:55 #62168

by johns

Replied by johns on topic LinuxCNC Features - a kind of NGCGUI

Finally started to use the Features for conversational programming.

Using FernV-linuxcnc-features-388af08.tar

Just to let you guys know, I, too, have the spindle set to 1,000 rpm, even if I ask for 2,000 rpm in the ToolChange window.

Using mill-mm, at about line 23 in the ngc file I have:

#<_spindle_rpm> = 1000

#<_final_spindle_rpm> = 1000

Then, later I have:

...

o<toolchng-001-ena> endif

S2000

F100.000

#<_final_feed> = 75.000

#<_final_spindle_rpm> = 2000

#<_ffeed> = 100.000

#<_vertical_feed> = 25.000

#<_plunge_down> = 0

#<_depth_step> = -0.500

#<_plunge_ratio> = 0.07

#<_pocket_ratio> = 0.80

(End tool change)

I wonder if the #<_spindle_rpm> should be set to 2000, and <#_ffeed> should also be set?

I'm ONLY boring circles out; the final cut does indeed go to 2,000 but all cuts to then are at 1,000 rpm.

Thank you!

Using FernV-linuxcnc-features-388af08.tar

Just to let you guys know, I, too, have the spindle set to 1,000 rpm, even if I ask for 2,000 rpm in the ToolChange window.

Using mill-mm, at about line 23 in the ngc file I have:

#<_spindle_rpm> = 1000

#<_final_spindle_rpm> = 1000

Then, later I have:

...

o<toolchng-001-ena> endif

S2000

F100.000

#<_final_feed> = 75.000

#<_final_spindle_rpm> = 2000

#<_ffeed> = 100.000

#<_vertical_feed> = 25.000

#<_plunge_down> = 0

#<_depth_step> = -0.500

#<_plunge_ratio> = 0.07

#<_pocket_ratio> = 0.80

(End tool change)

I wonder if the #<_spindle_rpm> should be set to 2000, and <#_ffeed> should also be set?

I'm ONLY boring circles out; the final cut does indeed go to 2,000 but all cuts to then are at 1,000 rpm.

Thank you!

Please Log in or Create an account to join the conversation.

- FernV

-

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

07 Sep 2015 16:45 - 07 Sep 2015 17:28 #62187

by FernV

Replied by FernV on topic LinuxCNC Features - a kind of NGCGUI

Hi Johns,

The solution is in the post #62149

Here is the easiest way until I post an update

Regards

Fern

The solution is in the post #62149

Here is the easiest way until I post an update

- Right-click on Tool Change in the top treeview and select 'Edit Current Feature'. It should open fv_tool-change.ini in gedit

- Go at the end of the file and add this new line after "F#param_feed" : #<_spindle_rpm> = #param_speed

- Save the file

- Right-click again on Tool Change in the top treeview and select 'Reload Current Feature'. It will load the updated version.

- Edit the values with the ones you entered before

- Delete the old one

Regards

Fern

Last edit: 07 Sep 2015 17:28 by FernV.

Please Log in or Create an account to join the conversation.

- FernV

-

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

07 Sep 2015 17:15 #62188

by FernV

Replied by FernV on topic LinuxCNC Features - a kind of NGCGUI

Hi fixer,

Regards

Fern

I added a combo where users specify if length entered is "overall" or "effective"ok, thanks for the updates,

regarding slots, i am not sure but i belive that the problem was that, as you say, the length is between centers, and i was wrongly expecting value between arcs...

Not very difficult. I added the option to my TODO list, but not sure it will be in the next update.I would also like to propose a small change in GUI: Can you make the Add feature window to not be additional window, but would show the menu in the "value" part of the main window? After you would choose feature to add it would disapear and normaly show values as before. I am using touchscreen and it is not convenient to have additional windows on top of main.

It needs only a single click now.And with touchscreen, taping on a feature or folder doesnt open it, it only selects and i have to press enter to open/add it. Can you do an option for adding a feature with single/double click? User with mouse will propably want double click.

Also added in my TODO list.A small popup numerical keyboard wich would show when selecting a value is propably too much to ask, a?

I am using Eclipse with PyDev plug-in. I think it is used for gmoccapy development. I never saw a line of Python code before a year ago. I think it is pretty easy to program though I always search for references and examples which are quite abundant. I could not find anything to help for drag and drop yet.I am learning python, but curently i am not good enought to make that kind of changes in your program...

You can edit features.py at line 66 and change to ICON_SIZE = 40. A quick fix less than perfect.and you can hide the shortcuts for features, as i personaly never use them, and make upper icons bigger, again because of touchscreen being inacurrate...

Regards

Fern

Please Log in or Create an account to join the conversation.

- andypugh

-

- Online

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

07 Sep 2015 17:26 #62189

by andypugh

There is a pre-existing pop up keyboard, I use it on my screens.

git.linuxcnc.org/gitweb?p=linuxcnc.git;a...67dd368594e90eb94ff2

Replied by andypugh on topic LinuxCNC Features - a kind of NGCGUI

Also added in my TODO list.A small popup numerical keyboard wich would show when selecting a value is propably too much to ask, a?

There is a pre-existing pop up keyboard, I use it on my screens.

git.linuxcnc.org/gitweb?p=linuxcnc.git;a...67dd368594e90eb94ff2

Please Log in or Create an account to join the conversation.

Time to create page: 0.201 seconds