NativeCAM is Features renamed

- newbynobi

-

- Offline

- Platinum Member

-

- Posts: 1930

- Thank you received: 394

deleting the complete NativeCAM directory and cloning again solved the issue.

Strange, that no even a git reset --hard origin/master solved the problem.

Now I need to find out, where to set some default values, as I want to use on every tool change the compensation from the tool file and all my tools should be used with flood cooling.

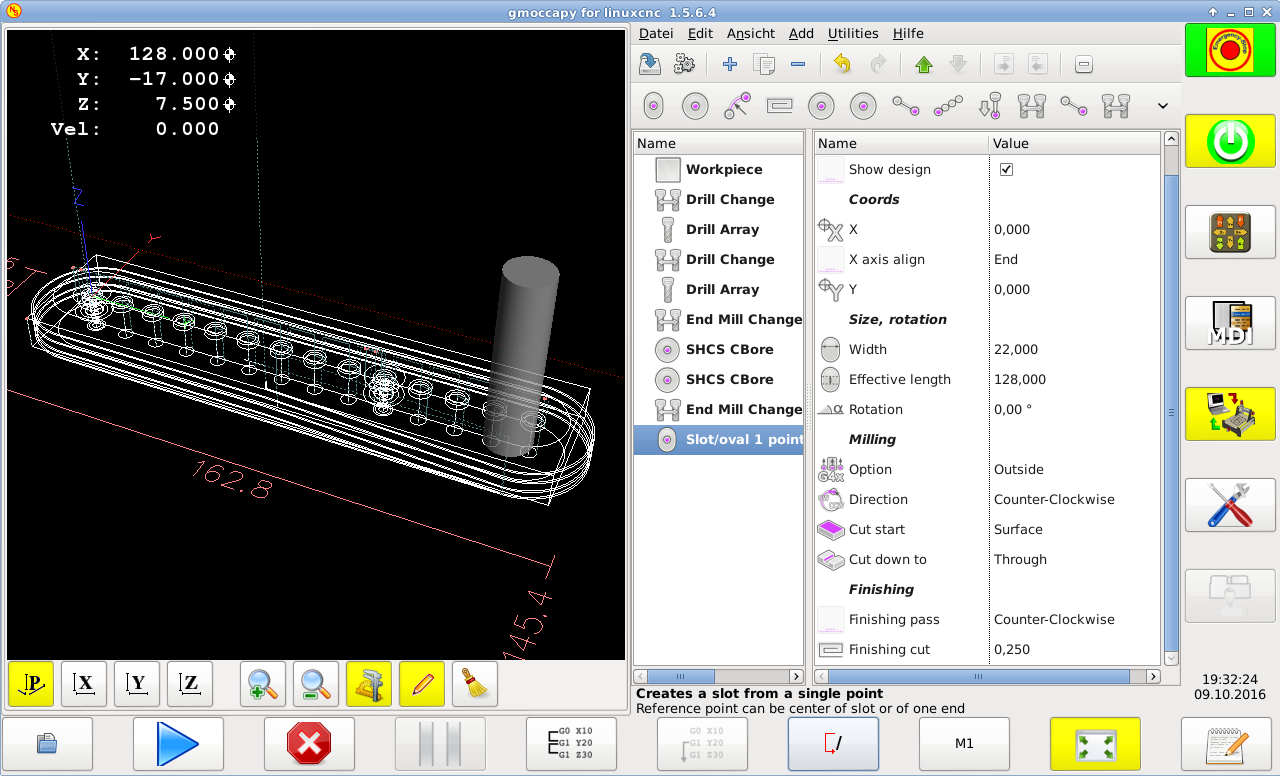

Also If I enter a feed of 750 on a slot/ovel 1 point outside milling, the machine does only 600 and speed is also lower.

I think this are those optimization factors.

Great work, I am very, very impressed!

Thanks for such a great tool. If I can support you to get it in master, just say hallo!

Norbert

Please Log in or Create an account to join the conversation.

- eFalegname

-

- Offline

- Elite Member

-

- Posts: 252

- Thank you received: 30

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 457

- Thank you received: 124

After updating LinuxCNC the problem with the screen is gone, but I still have a doubt I see that you must have the symbol "skip block" / active to run the gcode or I'm wrong?

You must "skip block". This is a safety feature. If not it would try to mill EVERY lines you see which many are just visual help to design your part

Glad to hear you have it working now. I just got back home and was about to study your post what I will do anyway to learn about possible problems

Post again for help when needed

Regards

Fern

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 457

- Thank you received: 124

Now I need to find out, where to set some default values, as I want to use on every tool change the compensation from the tool file and all my tools should be used with flood cooling.

Also If I enter a feed of 750 on a slot/ovel 1 point outside milling, the machine does only 600 and speed is also lower.

I think this are those optimization factors.

I changed default values for optimizing like in this shot

I also changed default values in Change Drill and Change End Mill to use length compensation and flood. It should not hurt if tool table value for Z is 0 or nothing is connected for flood, isn't it ? If you think it does, let me know please

I see you are learning quickly and I think you will just love polyline when you are familiar with it. I think it is the masterpiece.

About using Tool change for drilling, it is very good to exchange point of views on this and I wish that many others join this discussion so we can decide on the best approach for professionnals and hobyists alike and that LinuxCNC w/ NativeCAM may become one of the standards if not THE standard in the industry

I will make another post with what guides me on this

Best regards

Fern

P.S. it is possible to change default values in all *.cfg files. They must then be saved under a different name to prevent overwriting them. It requires the use of a menu-custom.xml which would not be overwritten. Drawback is you may not be aware of improvements and new files though you will be noticed of this and to try the new changes you would either have to load with the standard menu or open a cfg file and select the new files.

I think there is a way to do it but I am far from it now. It would be to have a 'init' section in each cfg files that execute as python code and set your personnalized values that would be entered in the Preference dialog. There are other priorities now.

Please Log in or Create an account to join the conversation.

- eFalegname

-

- Offline

- Elite Member

-

- Posts: 252

- Thank you received: 30

This morning I found a very strange behavior, I think it's better to illustrate it with a video, I do not know if I should do the steps in a certain order to get that these things do not happen

Please Log in or Create an account to join the conversation.

- vmihalca

- Offline

- Platinum Member

-

- Posts: 346

- Thank you received: 22

Like many others, I appreciate all your work on linuxcnc-features and now on this.

I didn't had the chance yet to use NativeCam, I will as soon as I get home.

I only have a lathe so I would need the Turning/Threading OD, ID functions. Are this supported in the new NativeCam ?

This weekend I've managed to cut my first thread using the code generated by linuxcnc-features.

Thanks in advance!

Please Log in or Create an account to join the conversation.

- eFalegname

-

- Offline

- Elite Member

-

- Posts: 252

- Thank you received: 30

Hi Fern.Glad to hear you have it working now. I just got back home and was about to study your post what I will do anyway to learn about possible problems

Post again for help when needed

Regards

Fern

Please could you describe me the installation procedure in my cnc, which files should I incorporate in my working configuration? I did the simulation and it seem to work but now I want to use it for real.

Thank you very much

Cheers

Floris

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 457

- Thank you received: 124

Hi Fern,

Like many others, I appreciate all your work on linuxcnc-features and now on this.

I didn't had the chance yet to use NativeCam, I will as soon as I get home.

I only have a lathe so I would need the Turning/Threading OD, ID functions. Are this supported in the new NativeCam ?

This weekend I've managed to cut my first thread using the code generated by linuxcnc-features.

Thanks in advance!

The same code that was developped couple of years ago is still available but I have done nothing yet to make it work in this new version. I think it will not work without a custom default.ngc to set basic parameters. When I think NativeCAM is stable with the way most users use it with their milling machine and plasma (some minor mods needed for plasma) I will work on lathe subroutines with your help. I have a lathe but it is not CNCed and I have no enough use of it to convert it.

On my PCs it is stable with minor issues due I think to pygtk bugs but nothing that hurts the operations

Best regards

Fern

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 457

- Thank you received: 124

This morning I found a very strange behavior, I think it's better to illustrate it with a video, I do not know if I should do the steps in a certain order to get that these things do not happen

If you do not follow a logical order, yes you will have messages from lcnc that some parameters do not exist.

Select them in the order they need to be executed like you do in any ngc file you would write yourself.

I watched you video and except for some warning that appears from times to times I have never them seen before.

On my pc's there are 2 messages that appears from times to times and when I tried to solve them (at least 5 times each) the cure was worst than the evil preventing values to be displayed. They do not hurt but I do not like having them and I found no way to make them not show. I think they are pygtk error.

When I started working on Nick's basic code 2 years ago there were some error checking code but no real handling of them and nothing very elaborated and at that time I knew nothing about python and linux. I now know a little more and with a lot of research on how to do this then that I have been able to improve his application to what it is now but far from perfect.

I can not reproduce the problems I saw but I wonder if it is due to your newer versions of python or others

I will start from the messages in the txt file you attached and write error handling when and if they shoe but YOU will have to test.

However there is a bad news : I have a plane to catch this Wednesday and will be back only at the beginning of November

I will read the forum whenever I can and answer from my phone

Regards

Fern

PS. For your cnc pc the information is in the ini file plus your will have to copy ncam.ui in the same directory as the ini or to a relative path from that directory. Before real working cut lot of air to make sure there is no problem with the pc and distro you have.

Please Log in or Create an account to join the conversation.

- vmihalca

- Offline

- Platinum Member

-

- Posts: 346

- Thank you received: 22

I've checked out a commit of nick before you started the work, and it does have all these lathe features but, it opens, I can enter values for stuff but I can't import the code into emc2.7.7

If you have any advices on that I would be grateful!

Please Log in or Create an account to join the conversation.