NativeCAM is Features renamed

- eFalegname

-

- Offline

- Elite Member

-

Less

More

- Posts: 252

- Thank you received: 30

10 Oct 2016 23:02 - 10 Oct 2016 23:14 #81534

by eFalegname

Replied by eFalegname on topic NativeCAM is Features renamed

Thank you Fern!, now I have a step by step workflow

Floris

Floris

Last edit: 10 Oct 2016 23:14 by eFalegname.

The following user(s) said Thank You: FernV

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

11 Oct 2016 00:56 #81535

by FernV

Hi

I spent time studying the file you posted and it lead me to functions I never really edited before because this code written by Nick never caused a problem. I think newer versions of python are more sophisticated and surprising events happened when the treestore was empty. I think I solved something and I encourage everyone to switch to the updated ncam.py

Please report

Best regards

Fern

P.S. Your video is very well thank you

Replied by FernV on topic NativeCAM is Features renamed

Fern, thank you very much for being so helpful, you've done a superlative tremendous nice job.

This morning I found a very strange behavior, I think it's better to illustrate it with a video, I do not know if I should do the steps in a certain order to get that these things do not happen

Hi

I spent time studying the file you posted and it lead me to functions I never really edited before because this code written by Nick never caused a problem. I think newer versions of python are more sophisticated and surprising events happened when the treestore was empty. I think I solved something and I encourage everyone to switch to the updated ncam.py

Please report

Best regards

Fern

P.S. Your video is very well thank you

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

11 Oct 2016 03:31 #81537

by FernV

Hi Florian

Congratulations for your DIY mill, it looks sturdy and well thought. I was pleased that you milled the demo wheel and since you did not ask any help, it makes me believe that it is intuitive enough. I wish you can use it for plenty of projects and if you find an issue or something to improve, ask me and I will try to answer asap.

Best regards

Fern

Replied by FernV on topic NativeCAM is Features renamed

Hi fernando.

I only say thank you and wish your and your familie all the best.

After i get nativecam working today , i am sure lcnc gets a lot more atractive because of you and your work.

Have a nice time and greedings from austria.

Florian

Hi Florian

Congratulations for your DIY mill, it looks sturdy and well thought. I was pleased that you milled the demo wheel and since you did not ask any help, it makes me believe that it is intuitive enough. I wish you can use it for plenty of projects and if you find an issue or something to improve, ask me and I will try to answer asap.

Best regards

Fern

Please Log in or Create an account to join the conversation.

- absolut15

- Offline

- Junior Member

-

Less

More

- Posts: 28

- Thank you received: 2

11 Oct 2016 13:57 #81548

by absolut15

Replied by absolut15 on topic NativeCAM is Features renamed

Hi Fern.

Thank you for your nice answer.

I have test natcam since yesterday , and there are no problems for me. All subrotins work fine together the probing things too.....

I finished build my diy mill the past week (buildtime about 4 weeks) and now its perfekt to get a big candy from you with natcam....

Its my secend mill i have . the first was a chines bf 25 clone.

And with this i use the old fern features . since its posible to include gmoccapy with your stuff, lcnc is much better to use .and simple things to milling get very easy.

Thanks again ....

Thank you for your nice answer.

I have test natcam since yesterday , and there are no problems for me. All subrotins work fine together the probing things too.....

I finished build my diy mill the past week (buildtime about 4 weeks) and now its perfekt to get a big candy from you with natcam....

Its my secend mill i have . the first was a chines bf 25 clone.

And with this i use the old fern features . since its posible to include gmoccapy with your stuff, lcnc is much better to use .and simple things to milling get very easy.

Thanks again ....

Please Log in or Create an account to join the conversation.

- eFalegname

-

- Offline

- Elite Member

-

Less

More

- Posts: 252

- Thank you received: 30

11 Oct 2016 15:10 - 11 Oct 2016 15:12 #81550

by eFalegname

Replied by eFalegname on topic NativeCAM is Features renamed

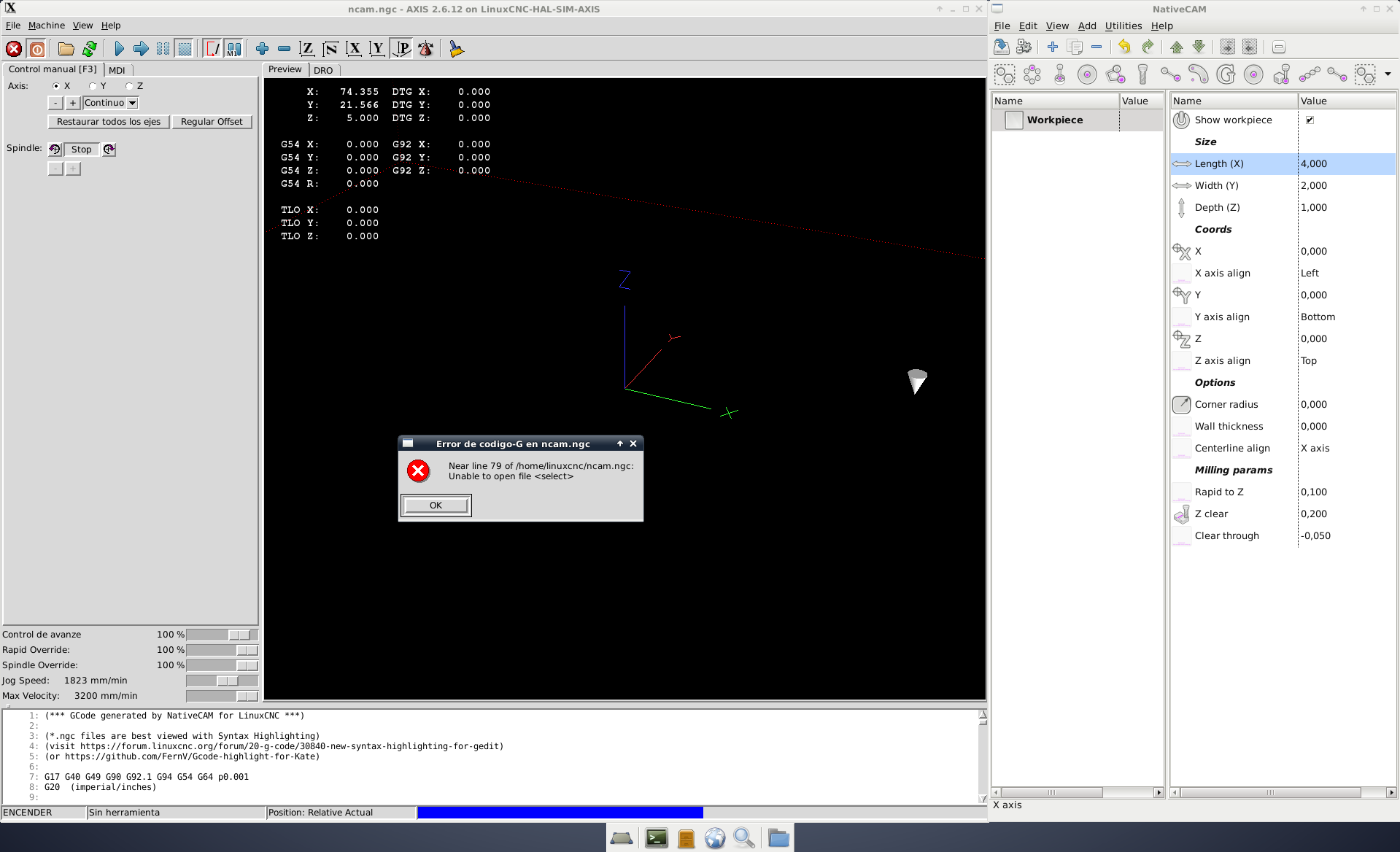

Hi again Fern,

something went wrong with my update, NativeCAM doesn't work anymore. Could you lend me a hand with it please?

something went wrong with my update, NativeCAM doesn't work anymore. Could you lend me a hand with it please?

Last edit: 11 Oct 2016 15:12 by eFalegname.

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

11 Oct 2016 22:11 #81567

by FernV

When I was developing and debugging I found it annoying to have times after times a request to mount a tool that was allready mounted, this is why it will not ask to remount it again. G49 is in my init string but I can only guess it is also in your's. Using T0 forces to unmount the tool at the end and when restarting since no tool is mounted it will ask for T7 and also issue G43.

I changed Change Drill and Change End Mill to issue G43 even if the tool is not remounted. I will later when I am back next month add in the Preferences dialog the option of forcing or not a remounting of the tool. I ran tests today and to me it seems OK now but my experience is limited with this compensation. G43 H parameter is the number of the tool selected so someone could select a different tool without mounting it for the length compensation but I have no idea at all why he would want to do this.

You stated it was the design you posted a screen shot, isn't it ? I will investigate from that point

What kind of behaviors are you talking about here ? I consider adding last code of T0 M6 G49 G0 X0 Y0 a temporary work around and will work to find a permanent solution

Best regards

Fern

Replied by FernV on topic NativeCAM is Features renamed

My 4.2 mm drill has a tool length offset of -6.25 mm. I touched off with tool 1 (tool length offset = 0), than I loaded tool T7 M6 G43 with offset -6,25 and started the code (just drilling), the tool begins drilling about the tool compensation over the workpiece and thats why it would not go through the workpiece.

Very strange, as If i unload the tool with T0 M6 G49 before starting the code, it is fine.

When I was developing and debugging I found it annoying to have times after times a request to mount a tool that was allready mounted, this is why it will not ask to remount it again. G49 is in my init string but I can only guess it is also in your's. Using T0 forces to unmount the tool at the end and when restarting since no tool is mounted it will ask for T7 and also issue G43.

I changed Change Drill and Change End Mill to issue G43 even if the tool is not remounted. I will later when I am back next month add in the Preferences dialog the option of forcing or not a remounting of the tool. I ran tests today and to me it seems OK now but my experience is limited with this compensation. G43 H parameter is the number of the tool selected so someone could select a different tool without mounting it for the length compensation but I have no idea at all why he would want to do this.

Next, after finishing the part, I just mounted a new part of material and pressed start again, but then your code moved the zero point of the part! The code finished with the tool in position X90 Y0 and after the restart the position X90 was X0!

You stated it was the design you posted a screen shot, isn't it ? I will investigate from that point

Also the tool compensation made strong behaviors.

What kind of behaviors are you talking about here ? I consider adding last code of T0 M6 G49 G0 X0 Y0 a temporary work around and will work to find a permanent solution

Best regards

Fern

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

11 Oct 2016 22:55 #81568

by FernV

I removed some code I added yesterday. It seems to me that it is buggy in python and I found another way to do it.

Hope it works for you now

Fern

Replied by FernV on topic NativeCAM is Features renamed

Hi again Fern,

something went wrong with my update, NativeCAM doesn't work anymore. Could you lend me a hand with it please?

I removed some code I added yesterday. It seems to me that it is buggy in python and I found another way to do it.

Hope it works for you now

Fern

Please Log in or Create an account to join the conversation.

- aer73

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 0

12 Oct 2016 12:10 #81571

by aer73

Replied by aer73 on topic NativeCAM is Features renamed

Please Log in or Create an account to join the conversation.

- FernV

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 457

- Thank you received: 124

12 Oct 2016 12:53 #81573

by FernV

Have you change the SUBROUTINE_PATH in the

inifile ? It is trying to execute select.ngc from lib/utilities

Read the ini files in the ncam_demo directories

Fern

Replied by FernV on topic NativeCAM is Features renamed

Many thanks to FernV for this great new tool for Linuxcnc.

Onething, i start Nativecam and when try to run any Feature i get an error,

Someone can help me with this?

My installation is under Debian.

Have you change the SUBROUTINE_PATH in the

inifile ? It is trying to execute select.ngc from lib/utilities

Read the ini files in the ncam_demo directories

Fern

Please Log in or Create an account to join the conversation.

- eFalegname

-

- Offline

- Elite Member

-

Less

More

- Posts: 252

- Thank you received: 30

13 Oct 2016 18:44 #81622

by eFalegname

Replied by eFalegname on topic NativeCAM is Features renamed

Thank you Fern, the new update works perfectly. Now I'm trying to get my tool change: I put M61 Q (T) at the beginning of each file, and then I do the Z tool touch off with a mobile probe plate

Please Log in or Create an account to join the conversation.

Time to create page: 0.136 seconds