Another plasma component...

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

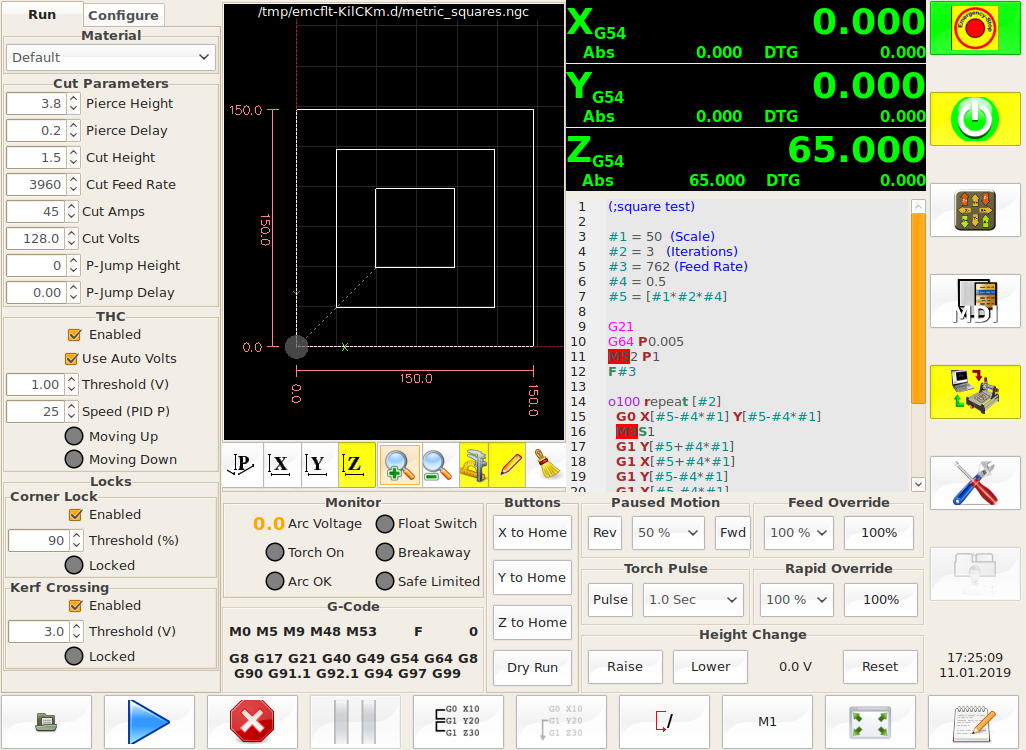

It appears under Gmoccapy in the Configuration Selector.

I am not sure about SpinButtons as I do not have a touchscreen so I am not sure what are the correct widgets to use.

github.com/phillc54/linuxcnc-plasmac

Cheers, Phill

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11722

- Thank you received: 3968

Please Log in or Create an account to join the conversation.

- sevaz

-

- Offline

- Junior Member

-

- Posts: 24

- Thank you received: 5

Info:

I've git cloned phillc54/plasmac repo, and then compiled it as a RIP package as well as a deb. Then i've tried both versions of debian - wheezy and stretch, but still nothing.

And one more question. As i'm also tried to connect pins to a real machine, i am also keep getting error messages "bottom limit reached

while THC moving down program is stopped......" and it doesn't matter NC or NO is the switch. It's probably connected with the problem mentioned above, because it also includes a Probe Switch Handler logic.

What am i doing wrong?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11722

- Thank you received: 3968

eg. Jog down until probe switch is triggered , then jog up until it turns off them do the G92. I just watch the light on my probe proximity sensor when doing this from my wireless pendant.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21342

- Thank you received: 7283

In the mean time i will continue to build and document the machines that are mentioned in this thread:

forum.linuxcnc.org/plasma-laser/35349-op...ea-and-a-lot-of-info

with the addition of a rotary axis that can be added to any of the above.

In the mean time, if anyone has the time and energy to investigate the possibility of adding the square and rectangular tube cutting to the gcodetools for Inkscape or NativeCam (Nick, i am looking at you !

From my experience, that thc_toma config ( again, i did not program all of it ) coupled with a Proma THC150 will put to shame most of the commercial machines costing many thousands of $, so adding this config coupled with mesa THCAD should make it go far beyond that, controlling the current from LinuxCNC on cheap Plasma current sources would get it nearly to Hypertherm level of automation.

I for one am not willing to give up on this, as the resignation from a very well paid job proves it.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11722

- Thank you received: 3968

I suspect his has been driven by one of its competitors and crappy performance from Mach3. Tell me does the Proma 150 have relays for its signals inside? I've heard it said it is held back by slow relays but I don't believe this is correct.

As far as a rotary axis goes, its rather simple on tube where it does not need a THC as the torch height is fixed above the tube and more complex on square/rectangular sections but you need a THC to lift the torch over the corners as they rotate.

You need to think in terms of folding the tube out flat and then it becomes a simple XY job. This coping calculator shows how this is done. I tested this years ago and it is possible to get highly accurate results with a cardboard template and an angle grinder! 90 degrees is easy but 45 degrees results in a deeper notch which is hard to get right. Sheetcam has a module for a wrapped rotary axis....

I think in time, Proma's biggest competitor might become a functioning LinuxCNC system.. Anyway I'm off to play on my machine this morning and to try a few ideas... and get a voltage feed into LinuxCNC.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Should only occur if the probe was tripped above the safe minimum distance below the Z axis maximum limit.material too high for safe traverse program is stopped...

Safe minimum distance is equal to pierce-height plus 1mm (pierce-height plus 0.039 inch).

Should only occur if the Z axis would reach the Z axis minimum limit during a THC directed move.bottom limit reached while THC moving down program is stopped......

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I don't think it matters where the Z axis is touched off as all Z axis moves are done using offsets.rodw wrote:

This is just a guess as I've not used this yet but I suspect you may need to touch off the Z axis manually in the MDI with G92 Zx where x is the material height. Think of this as part of your axis configuration.

It probably does look better in the preview (if in perspective view) if touchoff is done to the the top of the stock but in all my testing I only ever touched off once and that was 10mm below the Z axis maximum limit.

There should be NO Z axis moves in the gcode file.

Cheers, Phill.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21342

- Thank you received: 7283

Got my screens working properly and Linuxcnc on 64 bit Preempt-RT (again

BTW, here is the link to how Linuxcnc looks on that setup

forum.linuxcnc.org/51-ot-posts/35943-pro...reenshot-ever#125441

Regards,

Tom

Please Log in or Create an account to join the conversation.

- phillc54

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

That screen is AWESOME...tomylight wrote:

BTW, here is the link to how Linuxcnc looks on that setup

Cheers, Phill.

Please Log in or Create an account to join the conversation.