plasma control panel

- rodw

-

- Away

- Platinum Member

-

- Posts: 11666

- Thank you received: 3930

Depending on the circuit, a pullup or pulldown resistor is connected from the input to +V (pullup) or Ground (pulldown). This allows some current to pass through the circuit and "pull" the input high or low and thus prevent it to float.

One of my brutal learnings with plasma was that the 7i76e is a high impedance circuit. I think the book says there is 15k resistance from an input to ground. Depending on your plasma cutter design, this can be a problem as many relays have a minimum current spec and the high impedance means the current passing through the ArcOK dry contacts is well under the minimum relay spec and the oxide that builds up on the relay contacts is not burnt off during operation. This oxide builds up and can eventually prevent the relay from conducting the minimal current in the circuit from. This results in intermittent arcOK triggering after a period of time of perfect operation. Fortunately a couple of silver haired electronics guys I know that were old enough to have experience with analog circuits proposed this was what was causing my issues.

So we managed to unearth the data sheet for the plasma cutters dry contacts and calculated that we needed a 1k pullup resistor to ensure enough current for reliable relay operation. They then looked at the current draw and decided we needed a 1W resistor and Chris found a very old Australian made 4W resistor in his junk box so thats what is in my machine today. They warned me that it might take a few cycles to burn off the oxide but the machine quickly returned to normal relaiable operation.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11666

- Thank you received: 3930

I know John has his THCAD10 mounted at the plasma cutter but unless you graduate to a HF start like the Powermax 200, you don't need to do this. I have had no problems with noise with my 120 amp Thermal Dynamics machine with the THCAD in the cabinet.

Finally, if you are likely to go with a HF start machine, my HF guru has suggested the ArcOK signal passes into the cabinet using one of these (which needs bare metal contact to the cabinet).

au.element14.com/tusonix/2499-003-x5u0-1...gh-1000pf/dp/1186422

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

Stefan, when you have a digital input, the signal can sometimes "float" between on and off so you can get spurious triggering. This is not really likely with a 7i76e and a 24 volt logic signal as the voltage has to rise or fall a long way before it changes state but it can be a big problem with a 5 volt logic signal such as an Arduino (which has built in pullup resistors you can enable from software).

Depending on the circuit, a pullup or pulldown resistor is connected from the input to +V (pullup) or Ground (pulldown). This allows some current to pass through the circuit and "pull" the input high or low and thus prevent it to float.

One of my brutal learnings with plasma was that the 7i76e is a high impedance circuit. I think the book says there is 15k resistance from an input to ground. Depending on your plasma cutter design, this can be a problem as many relays have a minimum current spec and the high impedance means the current passing through the ArcOK dry contacts is well under the minimum relay spec and the oxide that builds up on the relay contacts is not burnt off during operation. This oxide builds up and can eventually prevent the relay from conducting the minimal current in the circuit from. This results in intermittent arcOK triggering after a period of time of perfect operation. Fortunately a couple of silver haired electronics guys I know that were old enough to have experience with analog circuits proposed this was what was causing my issues.

So we managed to unearth the data sheet for the plasma cutters dry contacts and calculated that we needed a 1k pullup resistor to ensure enough current for reliable relay operation. They then looked at the current draw and decided we needed a 1W resistor and Chris found a very old Australian made 4W resistor in his junk box so thats what is in my machine today. They warned me that it might take a few cycles to burn off the oxide but the machine quickly returned to normal relaiable operation.

Rod,

Do you use a pull up resistor on your Thermal Dynamics machine? If so could you give me a idea of how it is wired to your ArcOK signal.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

And also why don't you ditch the power supply for the THCAD and power it direct from TB3-6 and TB3-9 ?

I know John has his THCAD10 mounted at the plasma cutter but unless you graduate to a HF start like the Powermax 200, you don't need to do this. I have had no problems with noise with my 120 amp Thermal Dynamics machine with the THCAD in the cabinet.

Finally, if you are likely to go with a HF start machine, my HF guru has suggested the ArcOK signal passes into the cabinet using one of these (which needs bare metal contact to the cabinet).

au.element14.com/tusonix/2499-003-x5u0-1...gh-1000pf/dp/1186422

The reason I am still going to mount the THCAD-10 card externally from the control box is because I have already brought the metal box and step down power supply. Also when I brought my toroidal power supply I did not check its dimensions and when it arrived it was much bigger than I though it was going to be, Its taking up a lot of real estate in the control cabinet so externally mounting the THCAD-10 card frees up a bit of room.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11666

- Thank you received: 3930

Rod,

Do you use a pull up resistor on your Thermal Dynamics machine? If so could you give me a idea of how it is wired to your ArcOK signal.

Actually when I looked it was a pull down (connected to -24V)

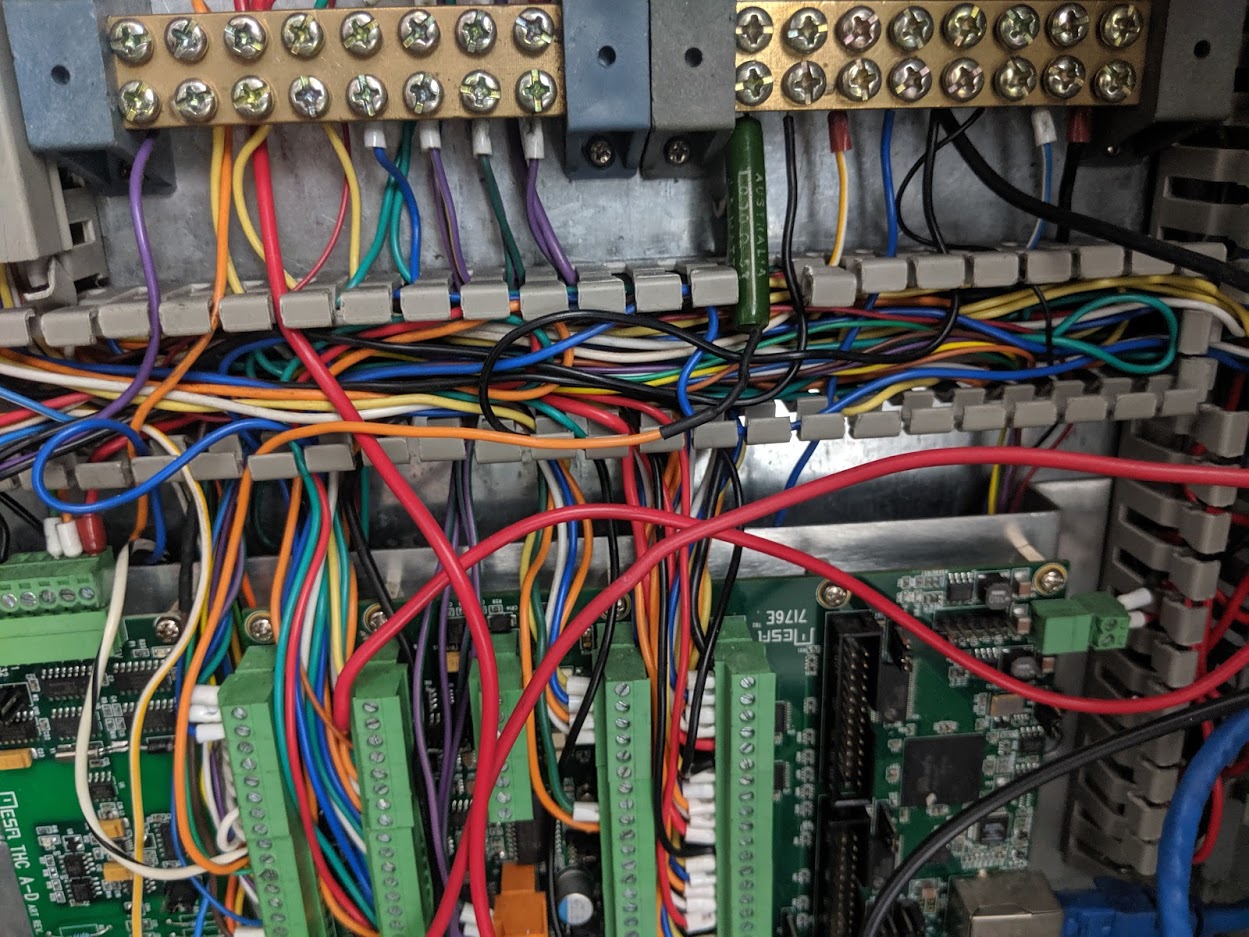

On my machine the busbar on the left is +24V and the right one is -24v

You can see the rather large and very historic Aussie made green resistor attached to -24v and the orange wire goes down to the input the arcOK wire is attached to. Its as simple as that. Keep some space around resistor as it may get hot.

Initially, I took it out when I upgraded to the TD A120 but I had some issues which were config related so I put it back in. I think I'll leave it there.

I've made a mess of the wiring when I added Ohmic sensing, I need to clean that up!

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

Rod,

If you could check my drawing of the resistor to input-21 and let me know if it looks right, I would very much appreciate it.

Attachment not found

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11666

- Thank you received: 3930

Where you have ArcOK Common going to TB-1, it should be going to Field Power as the input needs to see 24 Volts.

Also I went back through the emails from my Mate Chris and we settled on a 1k 1 W resistor which would draw 24 mA as a cleaning current. 220 Ohms would require a 3 Watt resistor or it would burn out.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

I have already brought a resistor as per Johns recommendation I brought a 220 ohm 5 Watt wire wound resistor,

I take it that since it is greater than 3 Watt it should be fine to use.

I really appreciate the help from everyone here, I should have my cabinet wired up this weekend and hopefully have the machine up and running next week.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

- Posts: 11666

- Thank you received: 3930

Thanks Rod,

I have already brought a resistor as per Johns recommendation I brought a 220 ohm 5 Watt wire wound resistor,

I take it that since it is greater than 3 Watt it should be fine to use.

I really appreciate the help from everyone here, I should have my cabinet wired up this weekend and hopefully have the machine up and running next week.

Stefan, that will be fine and result in 100 mA of cleaning current which is what was the minimum current draw of the relay Everlast used.

This is what my resident expert suggested

Rod, I forgot to calculate the power dissipation across the resistor. Unless you have a 3 Watt resistor, it will burnout.

It would be better to use 1000 ohm, giving a cleaning current of 24mA (if the resistor is rated at 1 Watt)

or, if you want the contact current to be around 50mA, 2 x 1000ohm 1 Watt resistors in parallel.

It is important to use resistors that can dissipate the power dropped across them.

A 220 ohm 5 Watt resistor would be OK. (giving a current of around 100mA

I have to say we are expecting great things of thefabricator in '19!

Really looking forward to seeing your machine cutting and your feedback about plasmac as it really just you and John who cut stuff commercially on a daily basis.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

Please Log in or Create an account to join the conversation.