Low budget plasma setup, what do I need?

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

08 May 2020 11:00 #167027

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

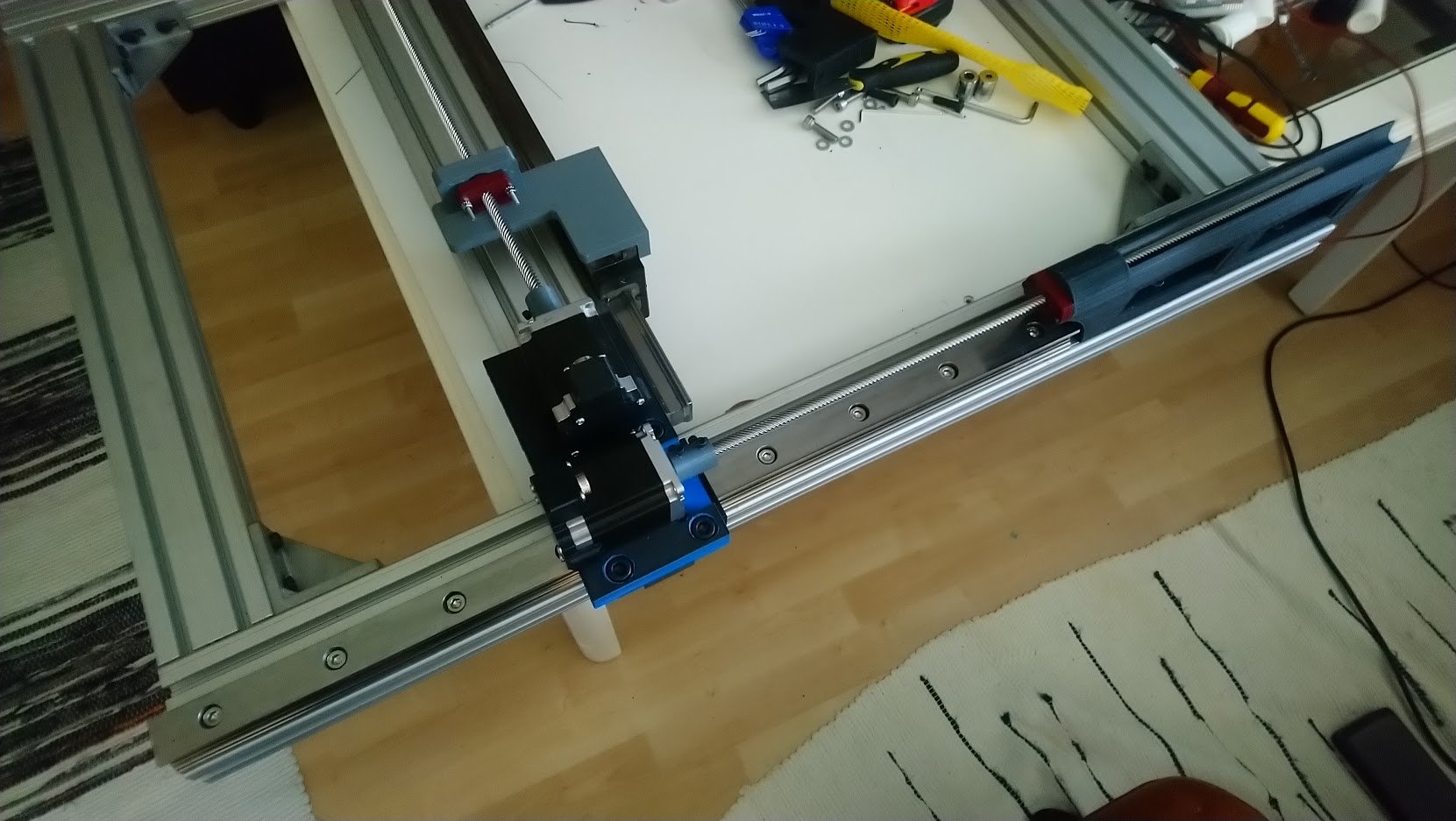

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

08 May 2020 11:04 #167030

by bbsr_5a

Replied by bbsr_5a on topic Low budget plasma setup, what do I need?

not a good part to be printet

and printed part on plasma is this realy a need why not using standard Parts like UCP and AL-Mount

and printed part on plasma is this realy a need why not using standard Parts like UCP and AL-Mount

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

11 May 2020 12:04 #167358

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Attachments:

The following user(s) said Thank You: Mike_Eitel, tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

11 May 2020 12:32 #167363

by tommylight

Replied by tommylight on topic Low budget plasma setup, what do I need?

They should do just fine, the only forces they are going to see is when changing direction, depending on the acceleration set.So my results must be pretty annoying for you bbsr_5a as all parts are 3D printed.

Please Log in or Create an account to join the conversation.

- machinedude

-

- Offline

- Platinum Member

-

Less

More

- Posts: 715

- Thank you received: 312

11 May 2020 22:30 #167429

by machinedude

Replied by machinedude on topic Low budget plasma setup, what do I need?

everything looks supper light so i don't think it will be a problem with everything as long as the weight is kept in mind. i don't even think acceleration will be to much of an issue with such a light weight build. I've see ATC tool changers made with mostly 3D printed parts that worked just fine. so it's an option if you have one to work with. it all depends on what you have to work with and basing your designs around what you can do yourself to keep costs down. that goes a long way as long as you can think outside the box  heck I've even seen a light duty router / engraver made with a 3D printer and was surprised by what it could do, i say print away as long as it lasts a while go for it. come to think of it i seen a 3D printed floating head for plasma done too

heck I've even seen a light duty router / engraver made with a 3D printer and was surprised by what it could do, i say print away as long as it lasts a while go for it. come to think of it i seen a 3D printed floating head for plasma done too

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

11 May 2020 23:47 #167439

by tommylight

Replied by tommylight on topic Low budget plasma setup, what do I need?

There is also a guy on youtube bending metal parts with 3d printed shapes, i just did not bother to check if they were plastic or sintered metal.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

12 May 2020 05:15 #167464

by Mike_Eitel

Replied by Mike_Eitel on topic Low budget plasma setup, what do I need?

They are plastic.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

12 May 2020 11:27 #167500

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Time to start pondering around Z axis and floating head.

So, is the floating head a must? Pros and Cons?

So, is the floating head a must? Pros and Cons?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21227

- Thank you received: 7249

12 May 2020 11:54 #167503

by tommylight

It is used to find the material and consequently adjust the pierce height and the cut height, the material will warp during cutting so that position changes, depending on the material being cut sometimes very much so.

Pro's = all

Con's = missed cut starts, torch touching the material during arc start messing the nozzle.

Replied by tommylight on topic Low budget plasma setup, what do I need?

Yes it is for large cut areas, for that small one, not really.So, is the floating head a must? Pros and Cons?

It is used to find the material and consequently adjust the pierce height and the cut height, the material will warp during cutting so that position changes, depending on the material being cut sometimes very much so.

Pro's = all

Con's = missed cut starts, torch touching the material during arc start messing the nozzle.

The following user(s) said Thank You: tecno

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11666

- Thank you received: 3930

12 May 2020 21:15 #167559

by rodw

Replied by rodw on topic Low budget plasma setup, what do I need?

IF your torch has a shielded tip, you might be able to get away with just ohmic sensing but I think your machine doesn't. YOu really should have a float switch. PLasmac's new probing routine relies on it to provide room for the Z axis to slow to a stop. ie. YOu will need to allow some overtravel to allow for this..

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.196 seconds