Plasma Torch, first try and lots of questions

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

26 Apr 2019 10:32 #131938

by CNCFred

Plasma Torch, first try and lots of questions was created by CNCFred

Dear all,

I always wanted to have a cnc machine for fabricating more complicated parts in iron and maybe some arts stuff too.

I am an old IT guy and therefore producing something that lasts is nice for me .

I would like to build a plasma table with working size of 1000mm x 1000mm at least.

I choose to do a lot in iron since I have a welder, band saw and some basic tools available.

But I am not keen on inventing the wheel new which means if I don't need to do everything myself since I want to finish the project as well.

I went to a cnc shop (don't know if links are allowed) and since I was not convinced if I get everything straight and leveled (welded in iron) and it would be faster and easier to mount rails and rack and pinion to a t slot profile I bought some.

I bought Nut 10mm 45x90 3x1300mm and for the gantry each side 45 x 180 .

Three linear rails hsr20/ hsv20 and some THK hsr20r1ss wagons.

lots of t nuts and alloy plates for mounting the wagons on the 45x180, angle profiles etc.

as well I bought a ccm s35-150d as z axis .

One problem to solve now is to fit metal (table is going to be iron I have laying around (50x50x2 and 60x60x3 profiles) and the alloy parts together.

I read already some threads here in the forum which I find excellent, but still I have lots of questions which I hope you are kind to answer.

There are so many parts available and this is overwhelming and difficult to choose.

I would like to use ethernet connection controller 7i76e and some closed loop 3NM nema 23 stepper motors.

1)Is there a kit available? I saw different voltage possibilities but did not understand what the difference is.

1a) to the controller are all nema 23 closed loop motors compatible?

2) do the linear rails need a mechanical stop at the end? if yes how?

3) I wanted to square the gantry with two induction switches and read you need end switches at the other side as well which interrupt the power ? how is this achieved? relay or electronically?

4) very important question which I couldn't figure out is when I use rack and pinion do I need a reduction gear on the nema23 ?

I have seen some they use a 15 tooth wheel and have it spring loaded on the rack.

I already ordered modul 1 15x15mm racks.

I appreciate also having some links as answers.

thank you

Roman

I always wanted to have a cnc machine for fabricating more complicated parts in iron and maybe some arts stuff too.

I am an old IT guy and therefore producing something that lasts is nice for me .

I would like to build a plasma table with working size of 1000mm x 1000mm at least.

I choose to do a lot in iron since I have a welder, band saw and some basic tools available.

But I am not keen on inventing the wheel new which means if I don't need to do everything myself since I want to finish the project as well.

I went to a cnc shop (don't know if links are allowed) and since I was not convinced if I get everything straight and leveled (welded in iron) and it would be faster and easier to mount rails and rack and pinion to a t slot profile I bought some.

I bought Nut 10mm 45x90 3x1300mm and for the gantry each side 45 x 180 .

Three linear rails hsr20/ hsv20 and some THK hsr20r1ss wagons.

lots of t nuts and alloy plates for mounting the wagons on the 45x180, angle profiles etc.

as well I bought a ccm s35-150d as z axis .

One problem to solve now is to fit metal (table is going to be iron I have laying around (50x50x2 and 60x60x3 profiles) and the alloy parts together.

I read already some threads here in the forum which I find excellent, but still I have lots of questions which I hope you are kind to answer.

There are so many parts available and this is overwhelming and difficult to choose.

I would like to use ethernet connection controller 7i76e and some closed loop 3NM nema 23 stepper motors.

1)Is there a kit available? I saw different voltage possibilities but did not understand what the difference is.

1a) to the controller are all nema 23 closed loop motors compatible?

2) do the linear rails need a mechanical stop at the end? if yes how?

3) I wanted to square the gantry with two induction switches and read you need end switches at the other side as well which interrupt the power ? how is this achieved? relay or electronically?

4) very important question which I couldn't figure out is when I use rack and pinion do I need a reduction gear on the nema23 ?

I have seen some they use a 15 tooth wheel and have it spring loaded on the rack.

I already ordered modul 1 15x15mm racks.

I appreciate also having some links as answers.

thank you

Roman

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11491

- Thank you received: 3854

26 Apr 2019 11:23 #131942

by rodw

Replied by rodw on topic Plasma Torch, first try and lots of questions

1. no kit available. consider NEMA23 with a 48 volt power supply. Total amperage draw can exceed your power supply output by about 40%

1a. probably not but I have no experience

2. Yes. I just put a block of aluminium that stopped the carriages from coming off but the limit switches stop them from being hit.

3.If you use the master branch of LinuxCNC, yo can configure the gantry squareness by following the homing sequence documentation. Once you build the machine, home the gantry against limit switches. The measure squareness, and adjust offsets in the .ini file and rehome so the hardware is square. 10 minute job

4. Yes you need a reduction drive. I had the same question See forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

Finally, follow the plasmac developments in the "Another plasma component" thread. I've also written a how to install thread for plasmac in the last week. Plasmac will make your job easier but right now, it might take a bit more effort to install Linuxcnc (from source)

1a. probably not but I have no experience

2. Yes. I just put a block of aluminium that stopped the carriages from coming off but the limit switches stop them from being hit.

3.If you use the master branch of LinuxCNC, yo can configure the gantry squareness by following the homing sequence documentation. Once you build the machine, home the gantry against limit switches. The measure squareness, and adjust offsets in the .ini file and rehome so the hardware is square. 10 minute job

4. Yes you need a reduction drive. I had the same question See forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

Finally, follow the plasmac developments in the "Another plasma component" thread. I've also written a how to install thread for plasmac in the last week. Plasmac will make your job easier but right now, it might take a bit more effort to install Linuxcnc (from source)

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20917

- Thank you received: 7131

26 Apr 2019 15:13 #131971

by tommylight

Replied by tommylight on topic Plasma Torch, first try and lots of questions

Have a read through this, plenty of info there:

forum.linuxcnc.org/plasma-laser/35349-op...ea-and-a-lot-of-info

forum.linuxcnc.org/plasma-laser/35349-op...ea-and-a-lot-of-info

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

26 Apr 2019 16:49 #131999

by pl7i92

Replied by pl7i92 on topic Plasma Torch, first try and lots of questions

hi im in Germany

i own 4 plasmas for cutting sheet metal up to 3mm at 8m/min

there are SBR sets you can go for 1300mm

this is the cheepest version

it is at that space not the best to go

but HGH at that size are more expensive and it piles up until the tourch firers

so if you go only 1m/1m it is good at Ballscrew 1605 recomends are 2010 and a 20/25 Timingbelt AT5

so out of the 3Nm at 48V you get 4Nm as Gear ratio puts you up

also the speed of the 2010 will boost your cut

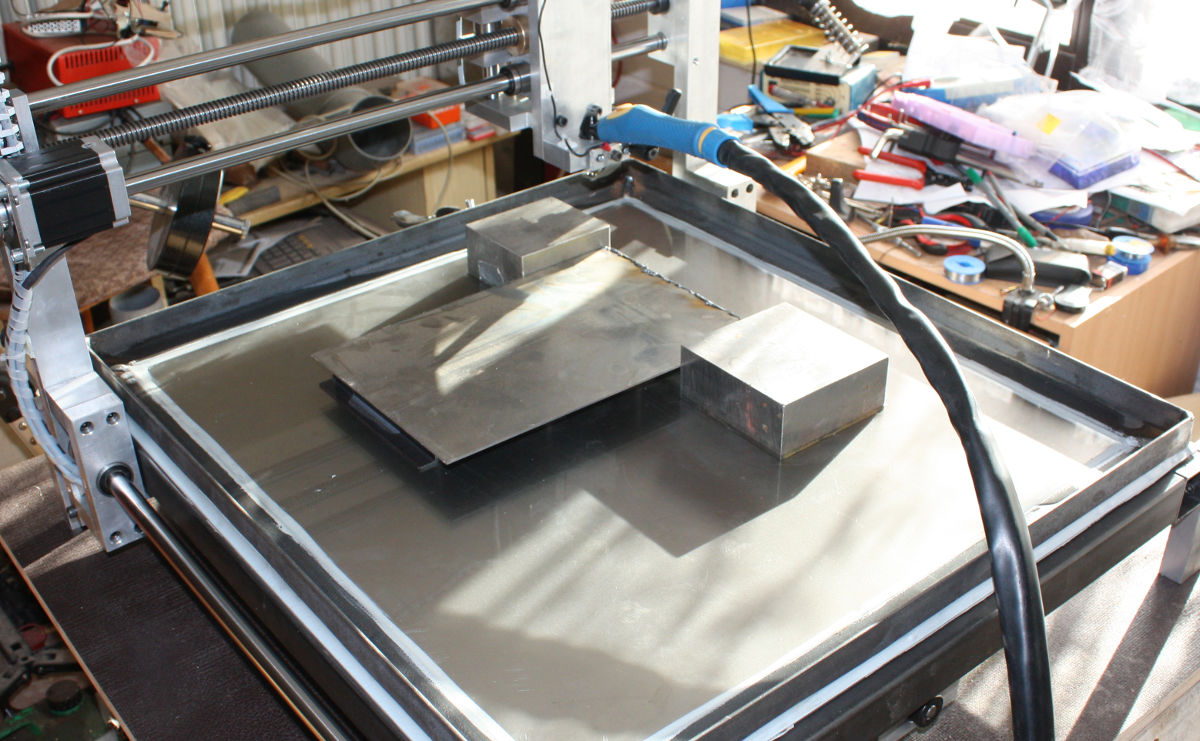

the image showes a lowest cost plasma at 700Euro with THC and Plasma Scut50

all inkluded made with a 16mm Drill on a RF50

i own 4 plasmas for cutting sheet metal up to 3mm at 8m/min

there are SBR sets you can go for 1300mm

this is the cheepest version

it is at that space not the best to go

but HGH at that size are more expensive and it piles up until the tourch firers

so if you go only 1m/1m it is good at Ballscrew 1605 recomends are 2010 and a 20/25 Timingbelt AT5

so out of the 3Nm at 48V you get 4Nm as Gear ratio puts you up

also the speed of the 2010 will boost your cut

the image showes a lowest cost plasma at 700Euro with THC and Plasma Scut50

all inkluded made with a 16mm Drill on a RF50

Attachments:

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

26 Apr 2019 19:38 - 26 Apr 2019 19:41 #132013

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

I have to google your appreviations ..

Sbr ..hgh...rf50

The idea I got from this video Plasmatable self made by DerNormio since I was told in the shop the stepper motors can't allow axial torque like shown in this video which was my favourite easy way to go in first place with a belt!!

So using rack and pinion I found next easier since he is not using a gear ratio ...

1mx1m is the size I would be able to cut, 1300 mm, I took because of the wagons etc.??

Sorry I am totally new to this area.

Sbr ..hgh...rf50

The idea I got from this video Plasmatable self made by DerNormio since I was told in the shop the stepper motors can't allow axial torque like shown in this video which was my favourite easy way to go in first place with a belt!!

So using rack and pinion I found next easier since he is not using a gear ratio ...

1mx1m is the size I would be able to cut, 1300 mm, I took because of the wagons etc.??

Sorry I am totally new to this area.

Last edit: 26 Apr 2019 19:41 by CNCFred.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

26 Apr 2019 20:16 #132016

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

Googled everything, yes thank you..ballscrew 2010 would be the way to go as well.

But having no experience with that I think they are not easy just to screw on and ready, more I don't know how to mount the motor on a system I make myself like this.

I am searching an looking for solutions which with drilling and bit of welding I can fix myself. Lots of searching.

Thx again

But having no experience with that I think they are not easy just to screw on and ready, more I don't know how to mount the motor on a system I make myself like this.

I am searching an looking for solutions which with drilling and bit of welding I can fix myself. Lots of searching.

Thx again

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20917

- Thank you received: 7131

26 Apr 2019 20:46 #132017

by tommylight

Replied by tommylight on topic Plasma Torch, first try and lots of questions

No balls crews on plasma cutters, to expensive and to much trouble to mount/install and way to slow for plasma and very hard to protect.

Small plasma = use belts they will last very long, just do not put them where the sparks could get to them.

Bigger ones, rack and pinion.

I will try to find the pictures, i have a 4x2 meter plasma cutter that uses ball screws just on Z axis ( two of them, had them so used them ) all other axis use belts.

SBR are round rails, and for the size you want they are usable, just keep in mind when doing the math that you need 2 of them on the gantry, while with HGR/HGH linear rails you can do it with a single rail on the gantry. For Z axis use allthread, M6 or M8 work nicely, a bit slow but does the job.

Small plasma = use belts they will last very long, just do not put them where the sparks could get to them.

Bigger ones, rack and pinion.

I will try to find the pictures, i have a 4x2 meter plasma cutter that uses ball screws just on Z axis ( two of them, had them so used them ) all other axis use belts.

SBR are round rails, and for the size you want they are usable, just keep in mind when doing the math that you need 2 of them on the gantry, while with HGR/HGH linear rails you can do it with a single rail on the gantry. For Z axis use allthread, M6 or M8 work nicely, a bit slow but does the job.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

26 Apr 2019 21:54 #132023

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

Please see my first post, I got :Three linear rails hsr20/ hsv20 and some THK hsr20r1ss wagons.

So x,y and for z I got the ccm s35-150d z axis

I ordered yesterday rack and pinion extendable modul 1 , 5x1m

The youtube videos provided showed what i had in mind belt and with rack & pinion.

Regards

So x,y and for z I got the ccm s35-150d z axis

I ordered yesterday rack and pinion extendable modul 1 , 5x1m

The youtube videos provided showed what i had in mind belt and with rack & pinion.

Regards

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20917

- Thank you received: 7131

26 Apr 2019 22:19 #132028

by tommylight

Replied by tommylight on topic Plasma Torch, first try and lots of questions

That will do nicely. I did read that, and while i was typing that last response was not sure if it was for this thread.

Sorry, but i read everything at the same time working with some electronics and some mechanics, not for the same machine!

Sorry, but i read everything at the same time working with some electronics and some mechanics, not for the same machine!

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

30 Apr 2019 05:33 - 30 Apr 2019 05:34 #132326

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

Hi,

my rack and pinion arrived yesterday .

I found a magnet of an old big SCSI hard disk which is very strong and easy to weld on for the breakaway torch holder.

A mini linear rail 9mm and a no name wagon should arrive today for the floating Z axis.

A:) I have no plan how to fabricate a reduction gear for the steppers so I started to calculate and there comes the question why do I need a a reduction gear?

The spur gear I selected has a travel radius of about 15mm which gives me with a 1.8degree step 0.471mm travel per step.

Using micro steps even less travel distance.

Is for CNC PLASMA half a millimeter not enough? in full steps? 1/8th micro stepping 0.058...

B:) my rack came without holes for mounting , I wanted to weld it on, since I changed my mind and used alloy I can't anymore. how did you mount it ? I think drilling holes is not precise enough ?

sorry for these questions.

Regards

my rack and pinion arrived yesterday .

I found a magnet of an old big SCSI hard disk which is very strong and easy to weld on for the breakaway torch holder.

A mini linear rail 9mm and a no name wagon should arrive today for the floating Z axis.

A:) I have no plan how to fabricate a reduction gear for the steppers so I started to calculate and there comes the question why do I need a a reduction gear?

The spur gear I selected has a travel radius of about 15mm which gives me with a 1.8degree step 0.471mm travel per step.

Using micro steps even less travel distance.

Is for CNC PLASMA half a millimeter not enough? in full steps? 1/8th micro stepping 0.058...

B:) my rack came without holes for mounting , I wanted to weld it on, since I changed my mind and used alloy I can't anymore. how did you mount it ? I think drilling holes is not precise enough ?

sorry for these questions.

Regards

Last edit: 30 Apr 2019 05:34 by CNCFred.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.266 seconds