Plasma Torch, first try and lots of questions

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11483

- Thank you received: 3851

30 Apr 2019 06:57 #132330

by rodw

Replied by rodw on topic Plasma Torch, first try and lots of questions

When you say your travel radius is 15mm, does that mean the radius of the pinion is 15mm?

What module gear and how many teeth on the pinion? Take it from me, its easy to make a mistake with the maths. What I thought was 30mm ws actually over 90mm per rev! Double check by marking one pinion tooth and roll it along the rack and measure with a ruler. I was way out! Give me those numbers and I'll check your maths.

Once I was alerted to the mistake I made by people on this forum, I had to refabricate my Z axis to include a reduction gear.

Its not about the accuracy, its about avoiding the slow RPM's that causes uneven movement which is a feature of steppers.

I bolted my rails on. Many people glue the racks on with adhesive tape. I'm not 100% sure what they use but if I did that I would use a 3M ATG 700 tape dispenser making sure I used the correct grade of permanent adhesive tape.

What module gear and how many teeth on the pinion? Take it from me, its easy to make a mistake with the maths. What I thought was 30mm ws actually over 90mm per rev! Double check by marking one pinion tooth and roll it along the rack and measure with a ruler. I was way out! Give me those numbers and I'll check your maths.

Once I was alerted to the mistake I made by people on this forum, I had to refabricate my Z axis to include a reduction gear.

Its not about the accuracy, its about avoiding the slow RPM's that causes uneven movement which is a feature of steppers.

I bolted my rails on. Many people glue the racks on with adhesive tape. I'm not 100% sure what they use but if I did that I would use a 3M ATG 700 tape dispenser making sure I used the correct grade of permanent adhesive tape.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

30 Apr 2019 07:30 #132333

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

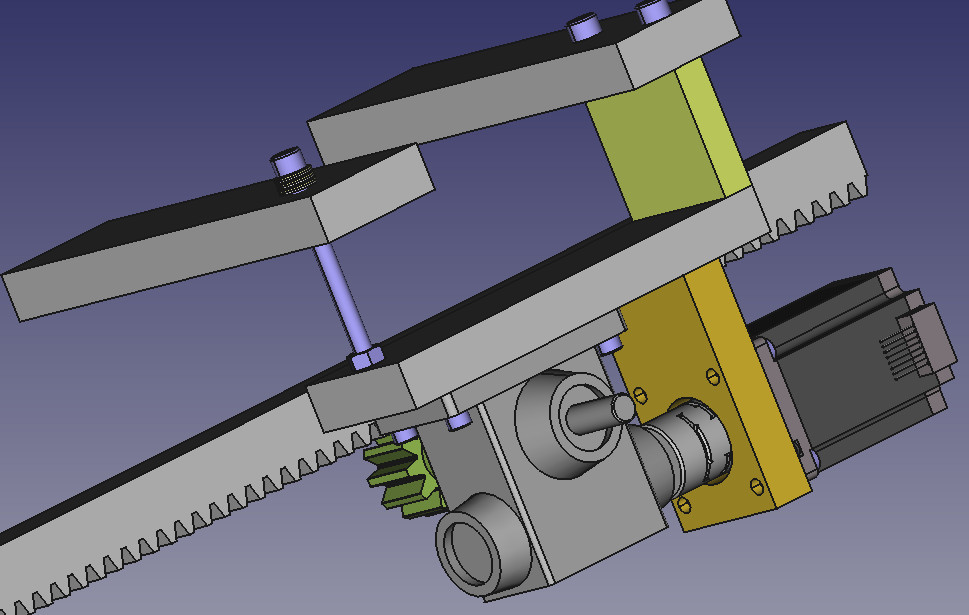

I boght module 1 racks and intend to use pinion with 15 teeth.

Pinion Module 1

Diameter d should be the travelling diameter, which makes my calc already wrong since I used that as radius!!

I was wondering why yesterday it was just the half:blink:

As mentioned the youtube video the guy is using no reduction gear and 15 teeth pinion on module1 rack.

Thx for the mounting information.

Thank you rodw for cnclinux config thread!

Pinion Module 1

Diameter d should be the travelling diameter, which makes my calc already wrong since I used that as radius!!

I was wondering why yesterday it was just the half:blink:

As mentioned the youtube video the guy is using no reduction gear and 15 teeth pinion on module1 rack.

Thx for the mounting information.

Thank you rodw for cnclinux config thread!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11483

- Thank you received: 3851

30 Apr 2019 10:12 #132335

by rodw

You are welcome.

You have made the same mistake as I did with the maths but I actually built my direct drive pinion and never used it! See this thread

forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

The distance traveled by your pinion per revolution is module 1 x 15 teeth x pi = 47.12mm per revolution. Measure it on the rack to see if I'm correct

The sweet spot for plasma most people suggest is about 25mm per rev. Tommy on that thread says its from 10-25mm per rev. So your machine would benefit from a 2:1 or 3:1 reduction gear which would give 15.6mm or 23.5mm per rev.

Good luck with it!

Replied by rodw on topic Plasma Torch, first try and lots of questions

I boght module 1 racks and intend to use pinion with 15 teeth.

Pinion Module 1

Diameter d should be the travelling diameter, which makes my calc already wrong since I used that as radius!!

I was wondering why yesterday it was just the half:blink:

As mentioned the youtube video the guy is using no reduction gear and 15 teeth pinion on module1 rack.

Thx for the mounting information.

Thank you rodw for cnclinux config thread!

You are welcome.

You have made the same mistake as I did with the maths but I actually built my direct drive pinion and never used it! See this thread

forum.linuxcnc.org/30-cnc-machines/31509...pinion-drive?start=0

The distance traveled by your pinion per revolution is module 1 x 15 teeth x pi = 47.12mm per revolution. Measure it on the rack to see if I'm correct

The sweet spot for plasma most people suggest is about 25mm per rev. Tommy on that thread says its from 10-25mm per rev. So your machine would benefit from a 2:1 or 3:1 reduction gear which would give 15.6mm or 23.5mm per rev.

Good luck with it!

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

30 Apr 2019 10:39 #132338

by pl7i92

Replied by pl7i92 on topic Plasma Torch, first try and lots of questions

you shoudt better calculate not on module

use the D0 diameter from the table of the manufacture and calculate by PI

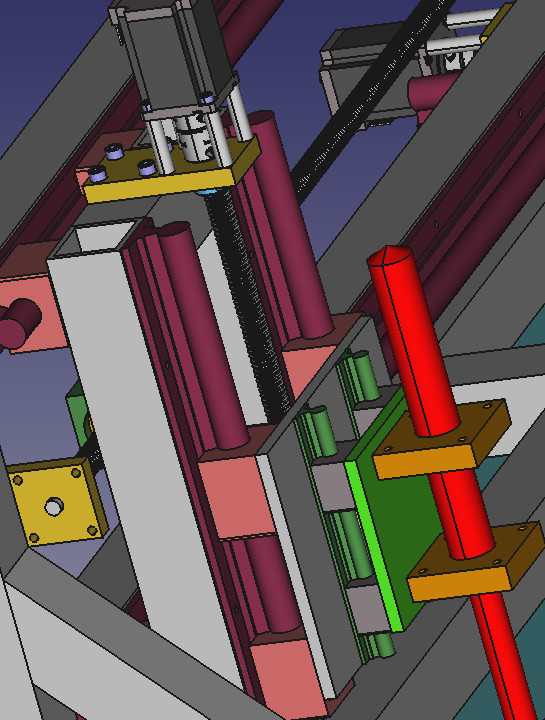

there are Metric Rack pinions that have a real precice workmessurments i use T5 or T10 Metric rack pinion

with the spring tighing system to the Axis it is so precice i never expected that at the speed and precision

even after 2 years we decided to go Gantry and the second gear has been the same

use the D0 diameter from the table of the manufacture and calculate by PI

there are Metric Rack pinions that have a real precice workmessurments i use T5 or T10 Metric rack pinion

with the spring tighing system to the Axis it is so precice i never expected that at the speed and precision

even after 2 years we decided to go Gantry and the second gear has been the same

Attachments:

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

30 Apr 2019 12:58 #132349

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

geared reduction closed loop

I am thinking of getting these ...i am still not clear about what driver and if those would work with 7i76e

to spend a few 100 bucks on it for experimenting I can't convince myself

rodw's calculation is right as well like pl7i92 ... I was only taking into consideration 1 step or microstep, not a whole revolution

I am thinking of getting these ...i am still not clear about what driver and if those would work with 7i76e

to spend a few 100 bucks on it for experimenting I can't convince myself

rodw's calculation is right as well like pl7i92 ... I was only taking into consideration 1 step or microstep, not a whole revolution

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

30 Apr 2019 14:40 #132354

by pl7i92

Replied by pl7i92 on topic Plasma Torch, first try and lots of questions

if you can go for it use the DM566 original leadshine >20m/min

if you are on low budget go for M542T abaut 10m/min

if you are even lowest use the TB6600 at 8USD with 36V and 3Nm Nema24 Steppers at 6m/min

if you are on low budget go for M542T abaut 10m/min

if you are even lowest use the TB6600 at 8USD with 36V and 3Nm Nema24 Steppers at 6m/min

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

30 Apr 2019 16:41 - 30 Apr 2019 17:57 #132359

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

The dm566 will it fit the www.omc-stepperonline.com/closed-loop-st...2804d-pg4-e1000.html

I thought closed and open loop are different drivers? I am lost!

And I find only dm 556 no 566.....so far they are openloop drivers

Should be the es-d508 closed loop druver for my selected geared motor...

I thought closed and open loop are different drivers? I am lost!

And I find only dm 556 no 566.....so far they are openloop drivers

Should be the es-d508 closed loop druver for my selected geared motor...

Last edit: 30 Apr 2019 17:57 by CNCFred.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11483

- Thank you received: 3851

30 Apr 2019 20:30 #132369

by rodw

Replied by rodw on topic Plasma Torch, first try and lots of questions

For NEMA23 and even small NEMA34's, I use Longs Motor DM542A which with the 7i76e give me 21 metres/min with 25x microstepping on 48 volt power. Save your money. you don't need closed loop steppers. With a 2:1 drive my guess you will have about 16-17 m/sec top speed.

With the 7i76e, work on about 750 rpm at the motor max. Previously with an Arduino, I could not get more than about 400 rpm

With the 7i76e, work on about 750 rpm at the motor max. Previously with an Arduino, I could not get more than about 400 rpm

Please Log in or Create an account to join the conversation.

- JTknives

-

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

03 May 2019 05:46 #132601

by JTknives

Replied by JTknives on topic Plasma Torch, first try and lots of questions

Do not weld your rack in place, that just screams lazy. Also the tape can work but it’s a very pitucular tape and really expensive. When I looked it up it was going to be a few hundred dollars for the roll of tape. I would recommend drilling it and bolting it to brackets.

The reasion you have to reduce the stepper is because of holding torque and acceleration. Steppers can start and stop fast but you need torque to move your weight. Also at the higher speeds that plasmas cut at you need to beable to stop the torch on a dime and change directions. The moving mass of the gantry will over power the stepper motor and you will loose steps and have wonky corners.

I REALY love my closed loop steppers. I tryied standard steppers and I was shocked how hot thy got just sitting there. I don’t have a heat problem with the closed loop and thy are MUCH quieter. And thy have more torque then a standard stepper of the same size.

The reasion you have to reduce the stepper is because of holding torque and acceleration. Steppers can start and stop fast but you need torque to move your weight. Also at the higher speeds that plasmas cut at you need to beable to stop the torch on a dime and change directions. The moving mass of the gantry will over power the stepper motor and you will loose steps and have wonky corners.

I REALY love my closed loop steppers. I tryied standard steppers and I was shocked how hot thy got just sitting there. I don’t have a heat problem with the closed loop and thy are MUCH quieter. And thy have more torque then a standard stepper of the same size.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

03 May 2019 06:46 #132607

by pl7i92

Replied by pl7i92 on topic Plasma Torch, first try and lots of questions

Attachments:

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.261 seconds