Plasma Torch, first try and lots of questions

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21148

- Thank you received: 7221

10 Mar 2020 12:53 #159648

by tommylight

Replied by tommylight on topic Plasma Torch, first try and lots of questions

2

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

10 Mar 2020 20:46 - 10 Mar 2020 20:48 #159697

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

Oh great that worked , even 2 motors on gantry , axis toolpaths are as they should be.

the machine is fighting I tell you , my home switches are the only pnp no , I use cat5 for connections and exactly on the two motor gantry one home did not work due to broken wire !!!

It took me a long time to find where.

I added the distance from home to max with 110 but when I travel the whole distance it show 470 only which is strange have to figure that out too.

further somehow the system is very slow I used the maximum which I could enter and still jogging is very slow.

I got 15.55mm travel per revolution that should be possible for much faster speed.

I add my ini and hal, since I got the wire problem I am already frozen in my unheated Garage.

in my unheated Garage.

thanks again for your help .....

the machine is fighting I tell you , my home switches are the only pnp no , I use cat5 for connections and exactly on the two motor gantry one home did not work due to broken wire !!!

It took me a long time to find where.

I added the distance from home to max with 110 but when I travel the whole distance it show 470 only which is strange have to figure that out too.

further somehow the system is very slow I used the maximum which I could enter and still jogging is very slow.

I got 15.55mm travel per revolution that should be possible for much faster speed.

I add my ini and hal, since I got the wire problem I am already frozen

thanks again for your help .....

Last edit: 10 Mar 2020 20:48 by CNCFred.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11604

- Thank you received: 3901

11 Mar 2020 11:02 #159769

by rodw

Replied by rodw on topic Plasma Torch, first try and lots of questions

i'm a bit rusty, but pretty sure that jog speed is determined by DEFAULT_LINEAR_VELOCITY in your ini file and its a lot lower than the MAX_VELOCITY you have in your joint configs. I kept the jogging a bit under the max velocities.

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

11 Mar 2020 20:24 - 11 Mar 2020 20:27 #159802

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

Hi Rodw,

thx, funny it does not allow me to go higher on DEFAULT_LINEAR_VELOCITY, jumps always back to 1000 max...

I remeber when I just tested one motor the 7i76e on my kitchen table it was much much faster with standard settings...

Maybe I have to discard all and start a new fresh new one setup??

thx, funny it does not allow me to go higher on DEFAULT_LINEAR_VELOCITY, jumps always back to 1000 max...

I remeber when I just tested one motor the 7i76e on my kitchen table it was much much faster with standard settings...

Maybe I have to discard all and start a new fresh new one setup??

Last edit: 11 Mar 2020 20:27 by CNCFred.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

11 Mar 2020 20:41 - 11 Mar 2020 20:55 #159803

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

Last edit: 11 Mar 2020 20:55 by CNCFred.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11604

- Thank you received: 3901

11 Mar 2020 21:14 #159808

by rodw

Replied by rodw on topic Plasma Torch, first try and lots of questions

Try typing a G0 command from the MDI and see if its faster. If you you have a setting preventing the jogging to use full speed.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

11 Mar 2020 21:37 #159814

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

tried that after studying G codes

same speed!!

I read nema23 should be possible at least a view hundred rpms...mine is very slow...

should I do a latency test?

the error I reverted to a previous version of ini and hal file ..hope that solves the error message ....

same speed!!

I read nema23 should be possible at least a view hundred rpms...mine is very slow...

should I do a latency test?

the error I reverted to a previous version of ini and hal file ..hope that solves the error message ....

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11604

- Thank you received: 3901

11 Mar 2020 22:21 #159816

by rodw

Replied by rodw on topic Plasma Torch, first try and lots of questions

It will be a configuration error in your in file I have to go so can't help

The following user(s) said Thank You: CNCFred

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

12 Mar 2020 06:55 - 12 Mar 2020 06:56 #159849

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

I use the great suggestion from swolebro to use the git repository and the different stages , so I should be able to go back one step

I will see today.

The speed of the motors is clear I only use pncconf which limit to velocity 2000mm/min max and 1000mm/min default which is slow.

So no problem with that, I asked Chris so he will maybe change since I like the wizard a lot.

forum.linuxcnc.org/39-pncconf/38556-defa...ocity-limited#159847

2000mm/min makes in my setup approx 2 rev/sec 33mm/sec travel distance 1.3 inch/sec.

I will see today.

The speed of the motors is clear I only use pncconf which limit to velocity 2000mm/min max and 1000mm/min default which is slow.

So no problem with that, I asked Chris so he will maybe change since I like the wizard a lot.

forum.linuxcnc.org/39-pncconf/38556-defa...ocity-limited#159847

2000mm/min makes in my setup approx 2 rev/sec 33mm/sec travel distance 1.3 inch/sec.

Last edit: 12 Mar 2020 06:56 by CNCFred.

Please Log in or Create an account to join the conversation.

- CNCFred

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 217

- Thank you received: 43

18 Mar 2020 20:16 - 18 Mar 2020 20:22 #160674

by CNCFred

Replied by CNCFred on topic Plasma Torch, first try and lots of questions

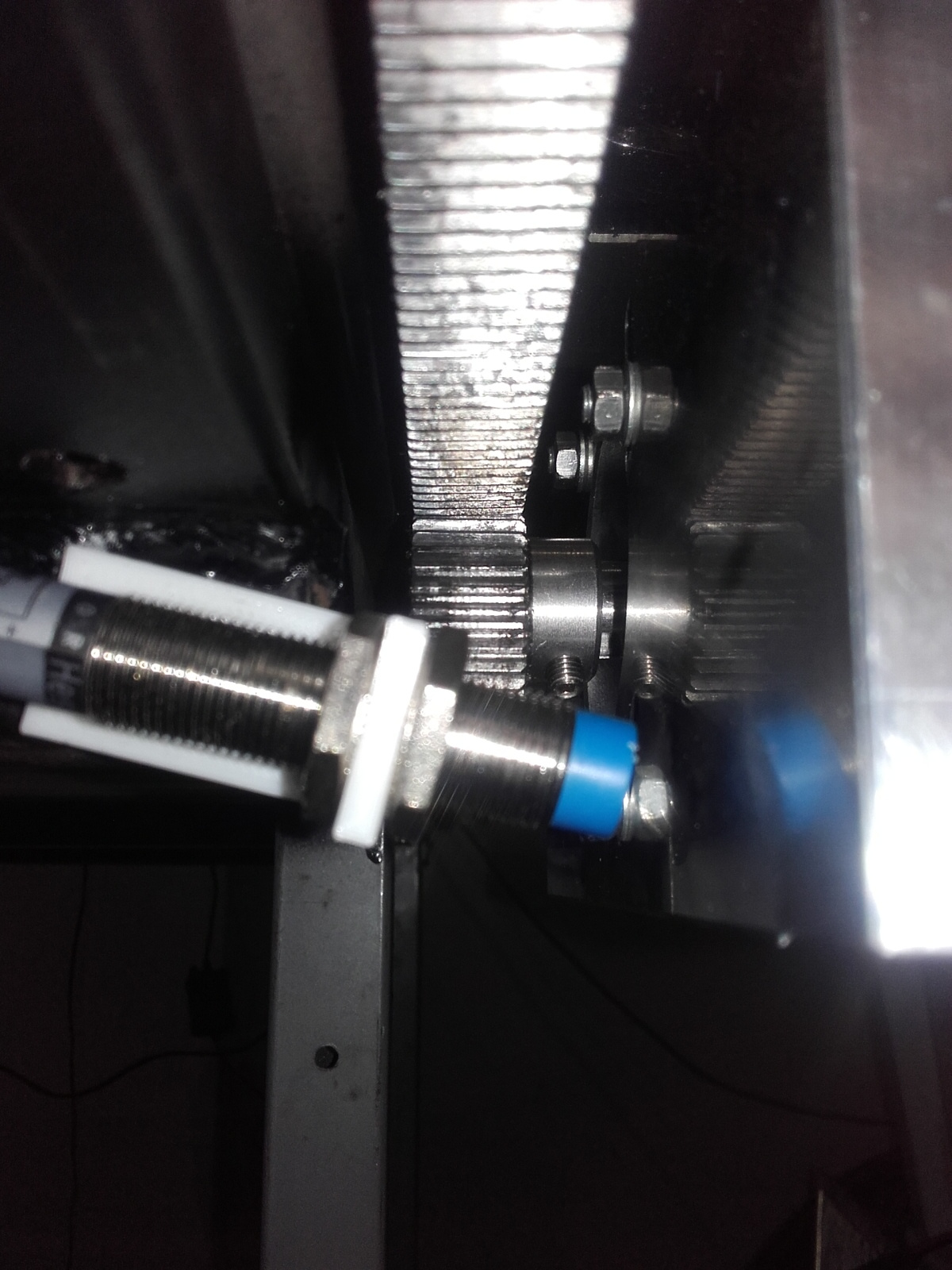

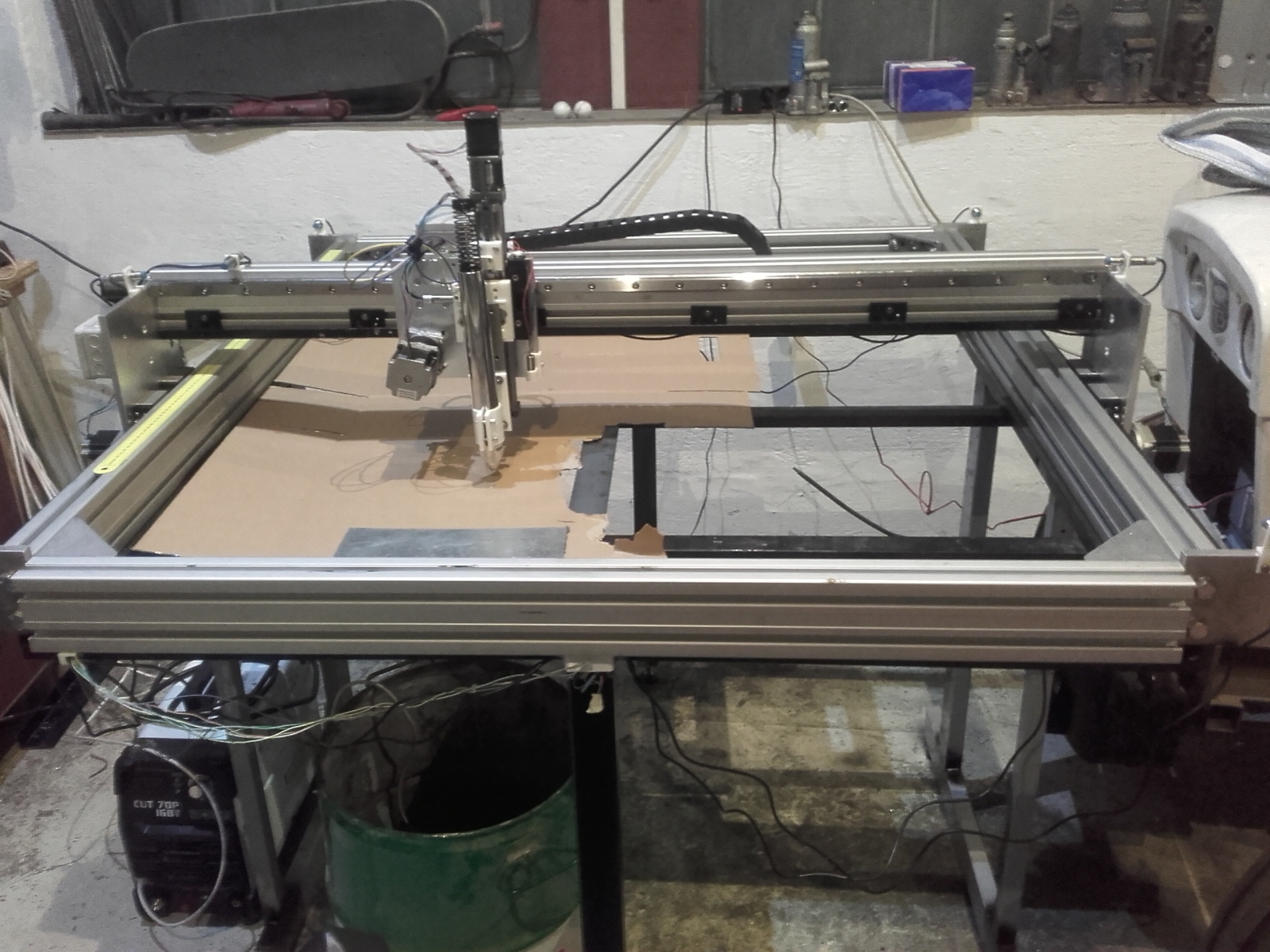

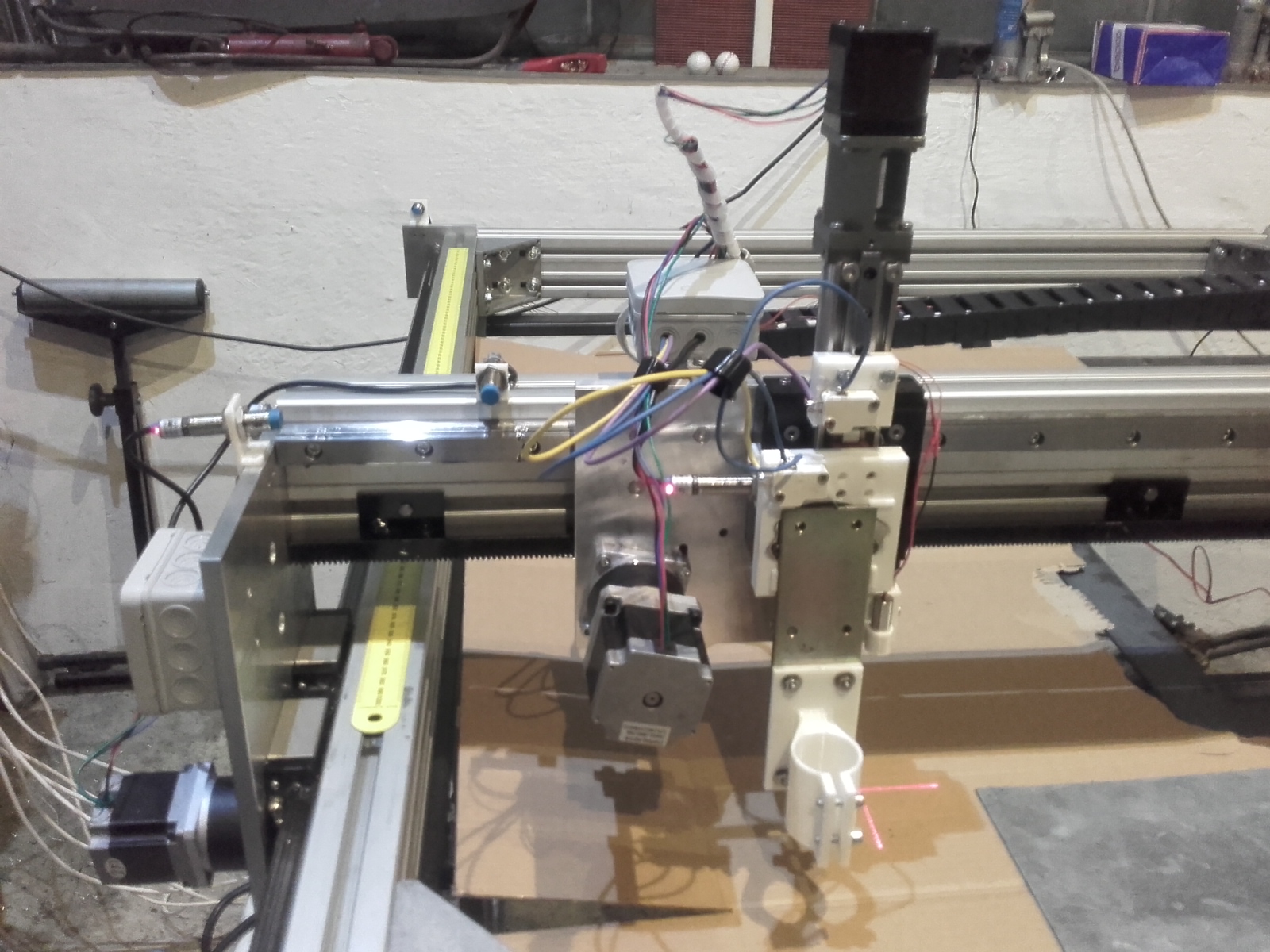

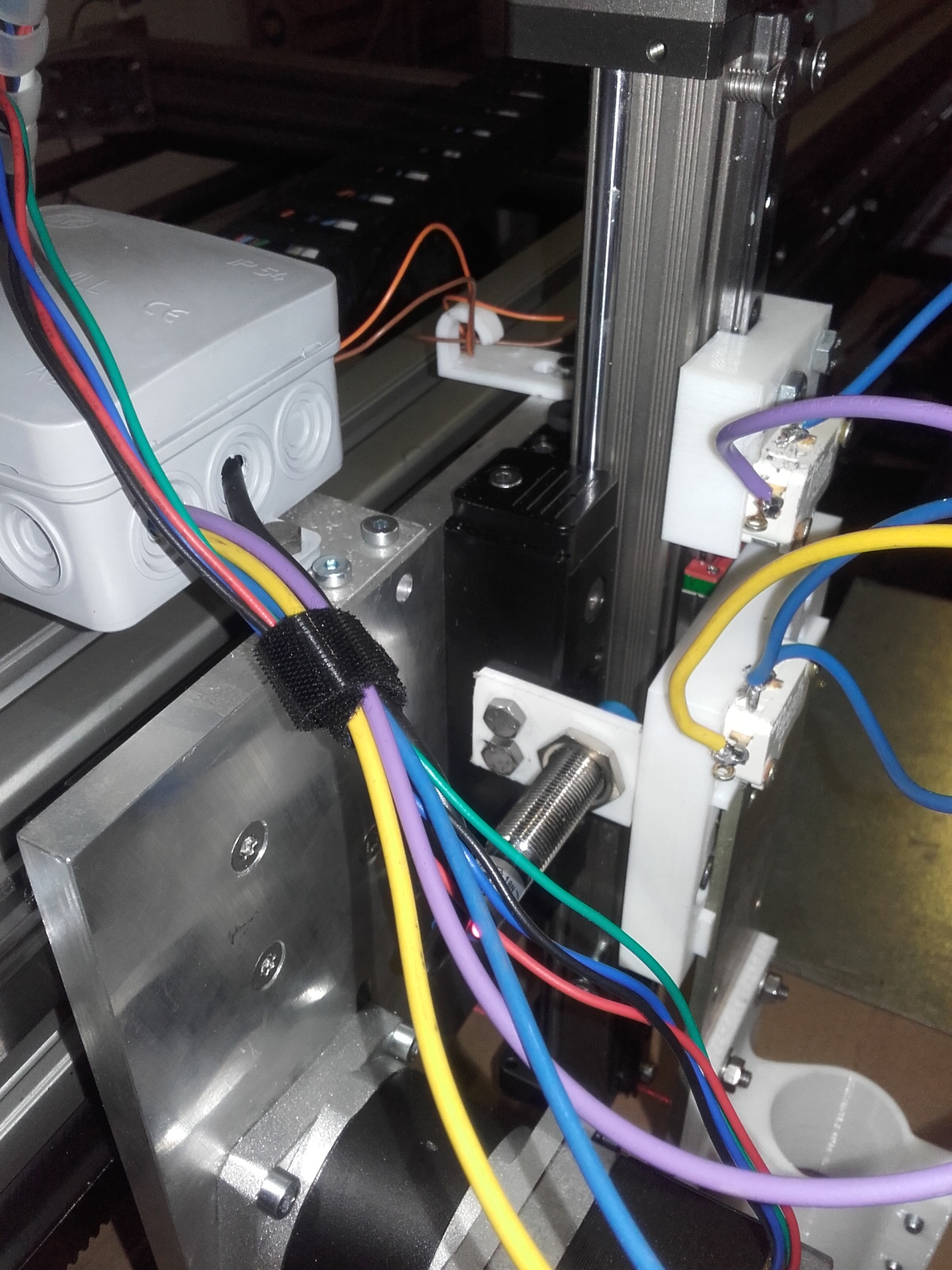

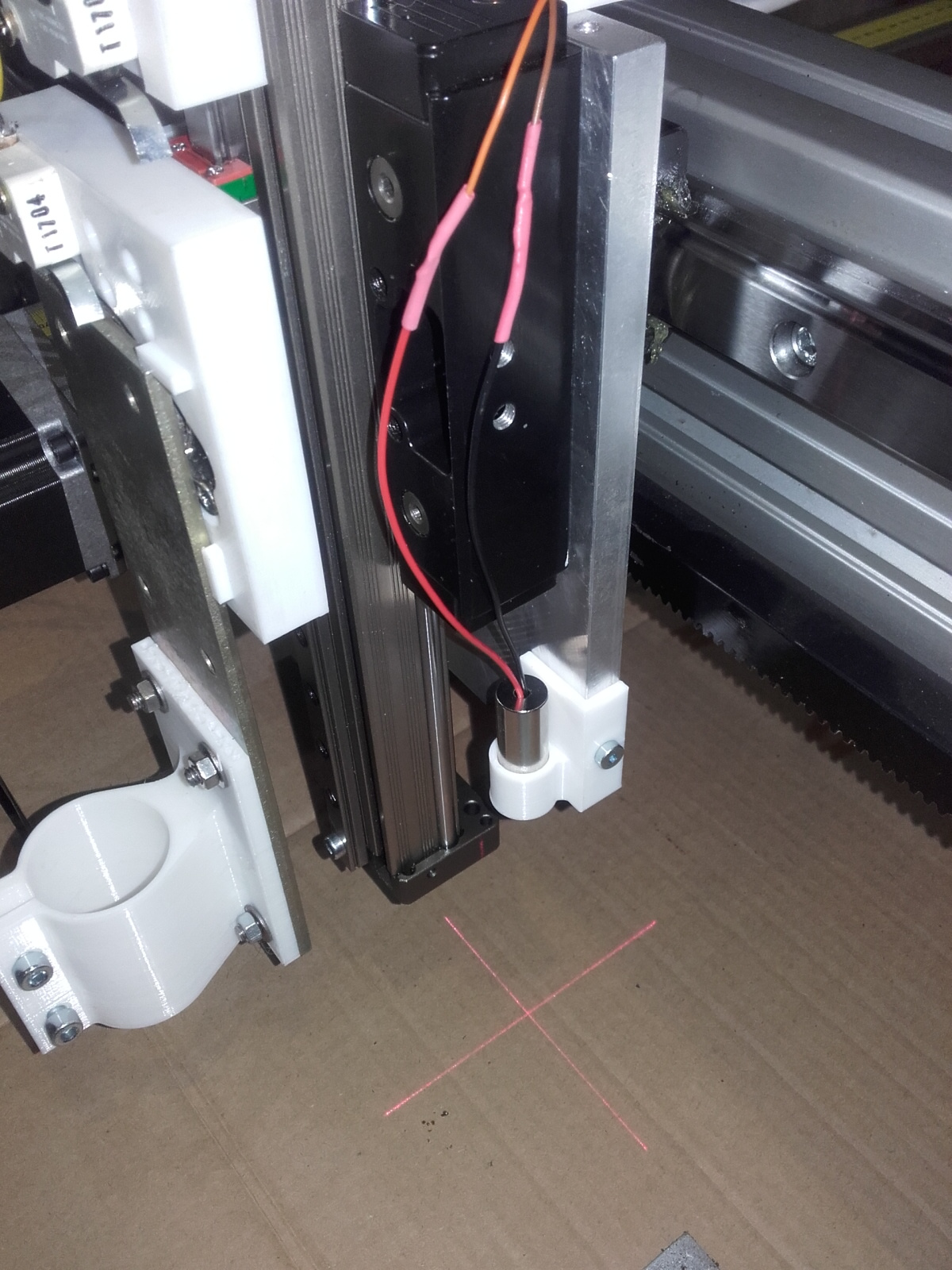

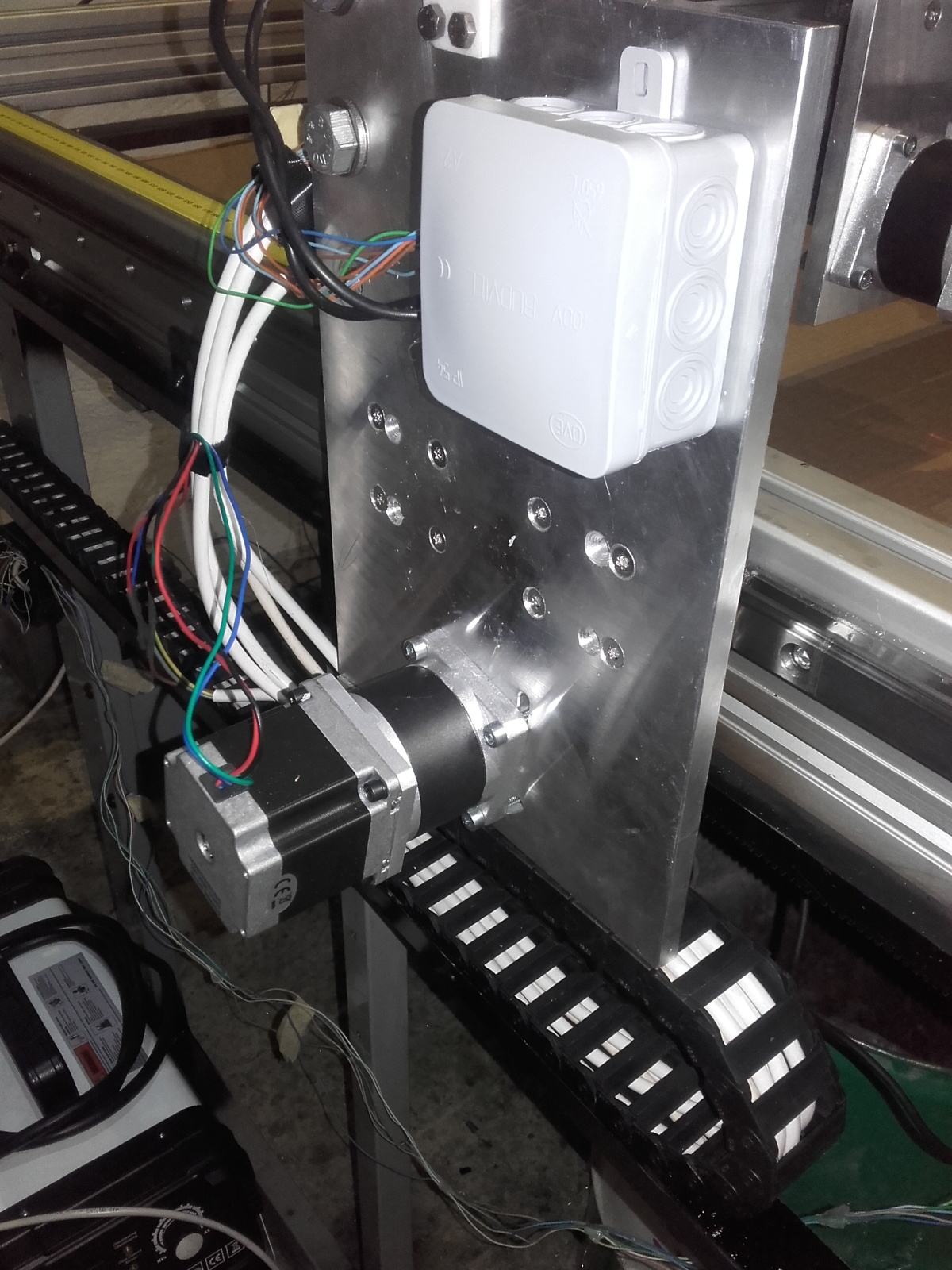

after a lot of help I got and still need , here some pics to view as thank you!!

I would make the gantry a big taller in height next time..wanted to make it flat but it's not necessary ...

home switch Y

setup for squaring and laser test

switches for power supplies motors and switches for motor drivers as well

I would make the gantry a big taller in height next time..wanted to make it flat but it's not necessary ...

home switch Y

setup for squaring and laser test

switches for power supplies motors and switches for motor drivers as well

Last edit: 18 Mar 2020 20:22 by CNCFred.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.246 seconds