Tumbler Build - For cleaning plasma cut parts.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

10 Apr 2020 09:18 #163463

by thefabricator03

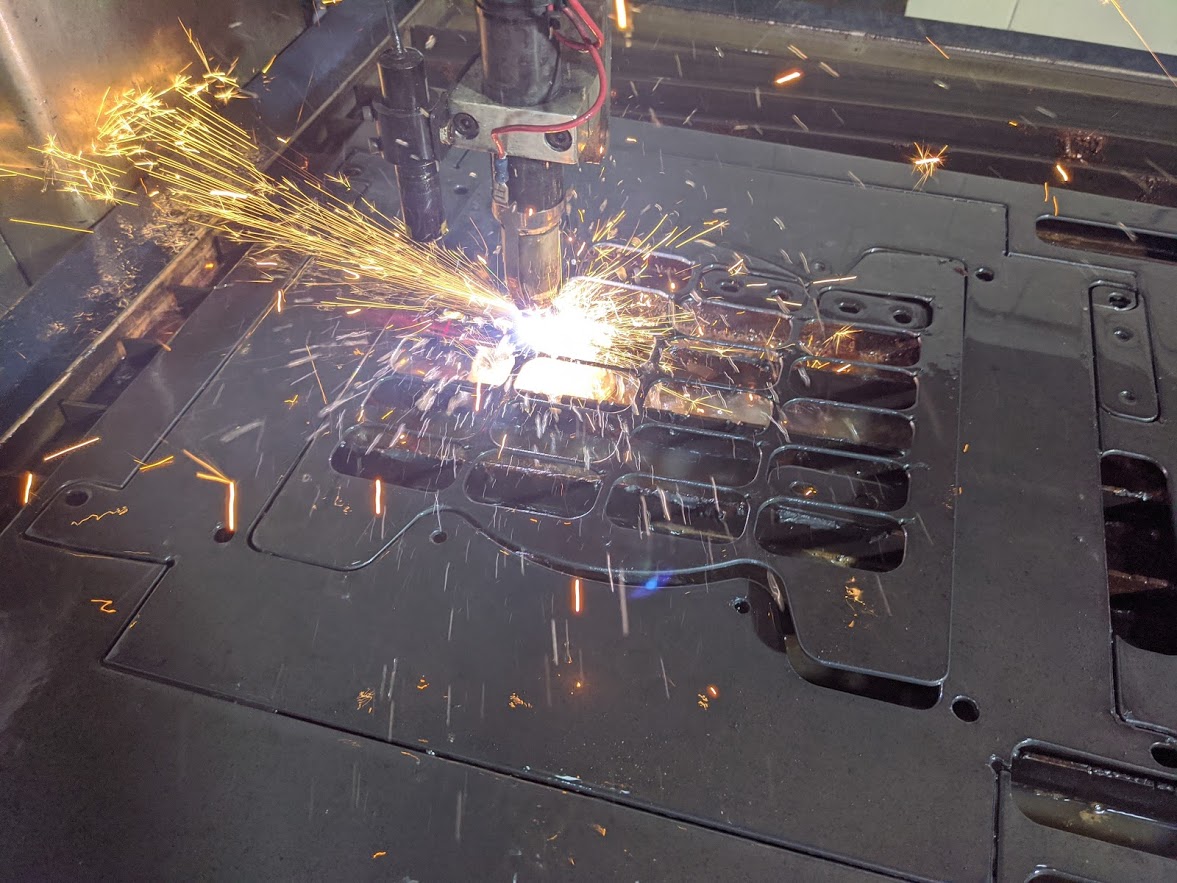

Tumbler Build - For cleaning plasma cut parts. was created by thefabricator03

Hi Guys,

I need to keep living up to my screen name and finish fabricating a few more project.

Next project is a tumbler to clean up our plasma cut parts.

This build will be a bit ad-hoc. I am not sure on how the machine will handle different loads. I have done the calcs but I want to do a bunch of testing before I fully finish it off.

I will assembly the drum and frame. Wire it up temporarily and test it with various loads. Depending on how the test go I will then build a enclosure for it,

It will be interesting to see just how loud the thing will be. I am looking at cheap sound proofing options. Tossing up how hebel panels for the enclosure walls would go.

Ill keep updating the pictures over the next couple of weeks.

I need to keep living up to my screen name and finish fabricating a few more project.

Next project is a tumbler to clean up our plasma cut parts.

This build will be a bit ad-hoc. I am not sure on how the machine will handle different loads. I have done the calcs but I want to do a bunch of testing before I fully finish it off.

I will assembly the drum and frame. Wire it up temporarily and test it with various loads. Depending on how the test go I will then build a enclosure for it,

It will be interesting to see just how loud the thing will be. I am looking at cheap sound proofing options. Tossing up how hebel panels for the enclosure walls would go.

Ill keep updating the pictures over the next couple of weeks.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

10 Apr 2020 09:21 - 15 Apr 2020 11:45 #163464

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

2 HP motor

Gearbox, cant remember the exact specs - I brought it two year ago, Ill look them up.

VFD

Bearing housing

Chain

Latches and high tensile bolts

Gearbox, cant remember the exact specs - I brought it two year ago, Ill look them up.

VFD

Bearing housing

Chain

Latches and high tensile bolts

Last edit: 15 Apr 2020 11:45 by thefabricator03.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

10 Apr 2020 12:45 #163472

by Leon82

Replied by Leon82 on topic Tumbler Build - For cleaning plasma cut parts.

Nice

Adding a drain may make it easier to regulate the water content

Adding a drain may make it easier to regulate the water content

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

10 Apr 2020 12:56 #163474

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

I might if needed. Kind of playing it by ear at this stage. Not a lot of information on the internet that I could find about tumblers for steel parts.

Plan on doing a bunch of testing and adding my experiences to this thread to help others out.

Anyone with something they think I should try should let me know.

Plan on doing a bunch of testing and adding my experiences to this thread to help others out.

Anyone with something they think I should try should let me know.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

10 Apr 2020 12:58 #163475

by rodw

Possibly add a swivel hose inlet to the shaft and let the water flow in...

Replied by rodw on topic Tumbler Build - For cleaning plasma cut parts.

x 2Nice

Adding a drain may make it easier to regulate the water content

Possibly add a swivel hose inlet to the shaft and let the water flow in...

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

10 Apr 2020 13:03 #163476

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

Lol no water will be added on purpose

I have had some guys tell me to add the steel punching we collect from our punch and shear machine. They work like ball bearings to help remove mill scale and dross.

I am sure it will be noisy as hell tho.

I have had some guys tell me to add the steel punching we collect from our punch and shear machine. They work like ball bearings to help remove mill scale and dross.

I am sure it will be noisy as hell tho.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11712

- Thank you received: 3963

10 Apr 2020 13:19 #163478

by rodw

Replied by rodw on topic Tumbler Build - For cleaning plasma cut parts.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

10 Apr 2020 13:25 - 10 Apr 2020 13:26 #163479

by thefabricator03

Replied by thefabricator03 on topic Tumbler Build - For cleaning plasma cut parts.

I built a tank for my machine so I can drain the water tray in about 10 mins and fill it back up again in about 6.

Last edit: 10 Apr 2020 13:26 by thefabricator03.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21282

- Thank you received: 7266

10 Apr 2020 15:22 #163497

by tommylight

Replied by tommylight on topic Tumbler Build - For cleaning plasma cut parts.

Nice, thank you.

Will have to build 2 of the vertical variety soon for tumbling wheel rims.

Will have to build 2 of the vertical variety soon for tumbling wheel rims.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

10 Apr 2020 16:38 #163508

by Leon82

Replied by Leon82 on topic Tumbler Build - For cleaning plasma cut parts.

In my experience with the tumblers they recirculate the water and tumbling fluid.

It can get sludgy and make the parts stick together so there is a happy medium.

They have tumbling fluid, and a rust prevent additives as well.

It can get sludgy and make the parts stick together so there is a happy medium.

They have tumbling fluid, and a rust prevent additives as well.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.223 seconds